Search

Search

Search

Search

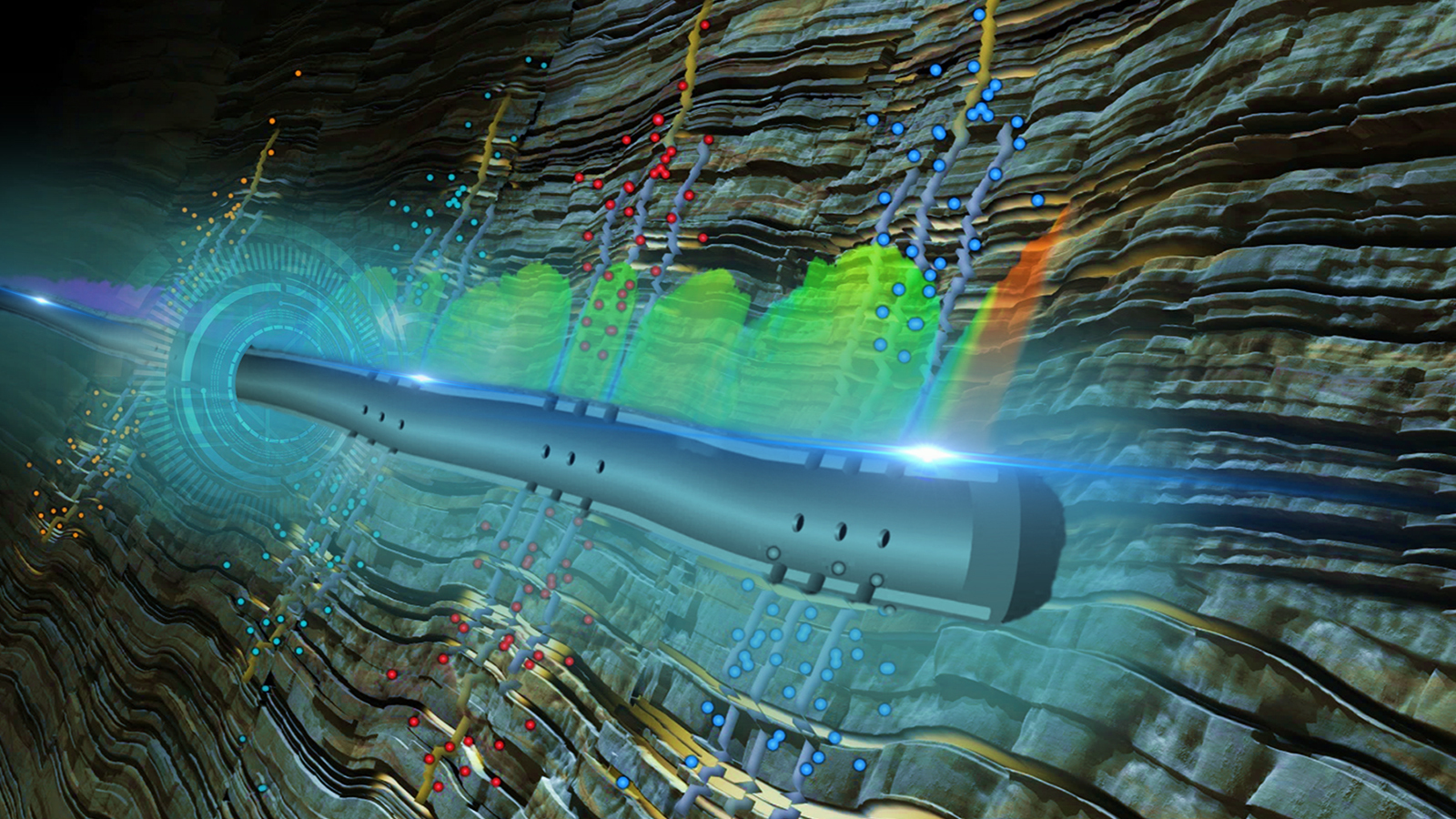

Halliburton provides scalable fiber optic sensing and real-time analytics that result in confident performance-enhancing adjustments to fracture designs

Talk to an expertHalliburton fracture monitoring solutions provide real-time, actional insights based on accurate analytics acquired from distributed temperature sensing (DTS) and distributed acoustic sensing (DAS). These insights allow operators to understand what is going on in the subsurface for confident design adjustments that improve fracture placement and performance.

Our fracture monitoring solutions are scalable, making fiber installation easier, faster, and more affordable, so operators can acquire real-time, actionable insights on more wells across their asset. These technologies deliver quantitative data for unconventional resources during stimulation and can be permanently installed or deployed as a retrievable solution.

World Oil Podcast Episode

In this episode, we explore the latest advancements in fracture monitoring technology. Discover how our Sensori service simplifies fracture monitoring with easy to deploy, non-intrusive diagnostics that lower cost and complexity, while providing continuous, real-time subsurface measurements.

Watch Podcast

An easy to deploy, cost-effective fracture monitoring solution for continuous measurement and visualization of the subsurface.

Explore

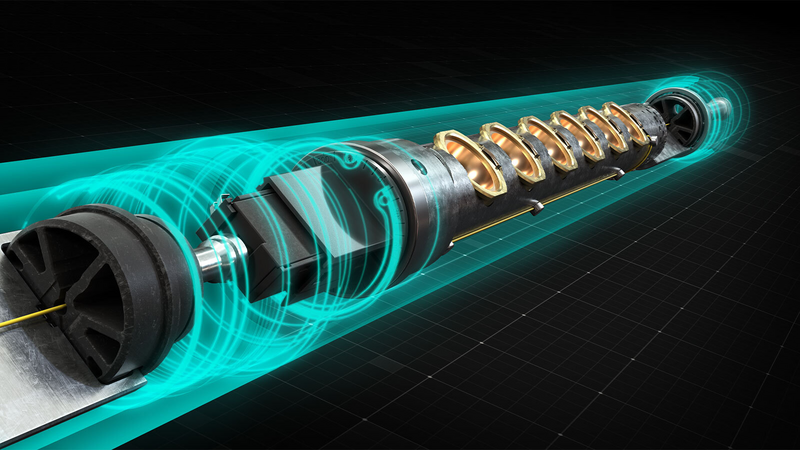

A step-change in the industry by integrating fiber optic and electric communication and power.

Explore

Acquire real-time well data without the need for intervention during frac interaction monitoring.

Explore

Velocity Revolve+™ guns are the industry's most accurate, compact, and versatile system for orienting perforations in fiber-optic completions.

Explore