Search

Search

Search

Search

Cementing and casing equipment solutions deliver improved performance and integrity throughout the life of the well

Talk to an expertHalliburton patented the two-plug cementing system in 1921 and continues to lead the oil and gas industry in innovation. We customize our cementing solutions using a comprehensive range of chemicals, advanced software to tackle specific well challenges, and the most efficient and reliable equipment for surface and casing applications. With over 100 cement labs globally, we tailor our solutions and services to meet the needs of our customers.

In 1929, Erle P. Halliburton commissioned a study of different cement blends. The resulting cement tables provided the foundation for the first Halliburton RedBook®. The field reference guide provides cementing calculations needed to drill, cement, and complete wells. It remains the oil and gas industry's go-to cementing service reference. A mobile app version of the RedBook cementing tables is available.

Explore SoftwareHalliburton uses innovative casing equipment technologies, automation, world-class cementing materials and services, and software modeling to tailor job designs. We help mitigate sustained casing pressure and fugitive gas emissions to achieve zonal isolation in deepwater and horizontal completions. Our engineered cementing and casing solutions enable high-quality projects that can maximize asset value.

Fit-for-purpose pumping and mixing equipment for both land and offshore, recognized worldwide for safety, effectiveness, and reliability.

Meet the unique pressure, temperature, and property demands of each well.

Achieve quick, accurate information on cement bond, casing evaluation, and well integrity.

Ensure wellbore-integrity and sound technical decision-making throughout the life of the well.

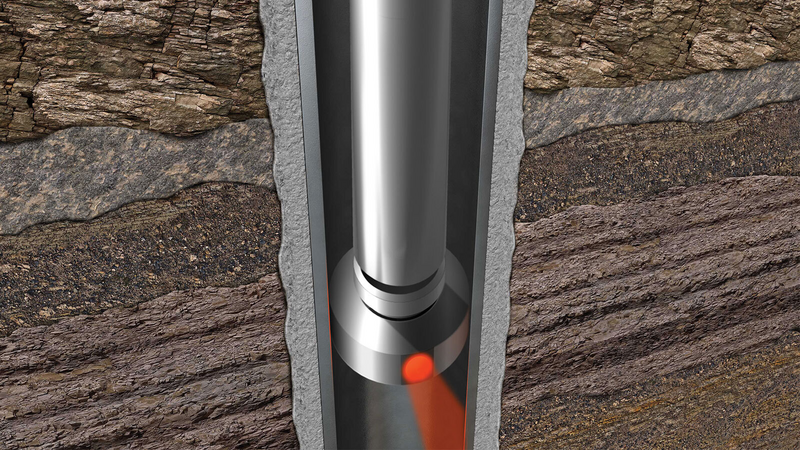

Secure the primary cement job amid extreme conditions and increase the return of uncontaminated mud to the surface.

Halliburton casing solutions help run and land casing to depth, ensure proper centralization, and achieve long-term zonal isolation.