Search

Search

Search

Search

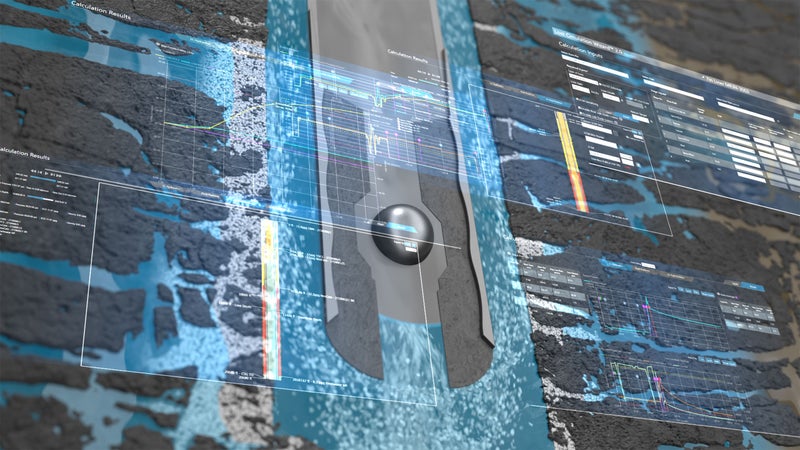

Halliburton provides the ability to assess and monitor critical variables before, during, and after a cement job to ensure integrity and zonal isolation

Talk to an expertGreater reservoir depth, downhole temperature, and pressure increasingly complicate wellbore challenges and achieving wellbore integrity. Through field-proven technical solutions, laboratory-driven empirical data, and robust applied-design tools, Halliburton Cementing helps operators ensure successful job design, primary cementing, and wellbore integrity through the well’s lifecycle.

Cementing barrier design and tailoring digital twin software that enables real-time job monitoring, evaluation, and instantaneous barrier validation.

Lost Circulation Wizard™ software allows Halliburton technical professionals to predict the optimal LCM/fluid package to mitigate losses during and after cement operations.

Evaluating LCM selection and concentration for optimal passage, suspendability, and transport.

Tailored design decisions employed by machine learning to improve the probability of operational success.

Advanced FEA analyzes the casing, cement sheath, and formation information to determine the cement mechanical properties necessary for long-term integrity.

We offer the Halliburton eRedBook® Mobile application as a free download. The app uses Halliburton Cementing Tables, the industry-preferred data reference for calculations used in drilling, cementing and/or completing oil and gas wells.

Download APP