Search

Search

Search

Search

As the landscape of oil and gas operations, geothermal energy, mining, and carbon capture, utilization, and storage (CCUS) continues to evolve, maintaining wellbore integrity during production and abandonment phases is crucial. Traditional well construction practices typically focus only on short-term cement mechanical properties and safe placement.

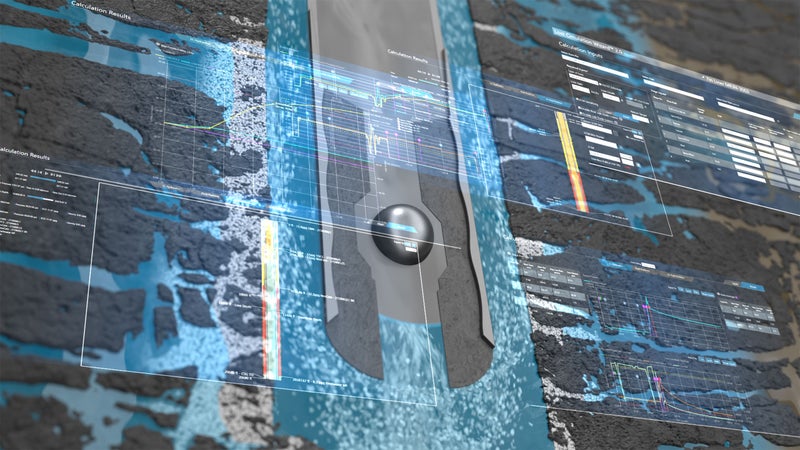

WellLife® software, a well integrity digital twin, uses advanced finite element analysis (FEA) models to evaluate the performance of cement systems or sealants under various operational and environmental stresses. Applications include conventional oil and gas production, geothermal resources, CCUS, lithium extraction, hydrogen storage, and plug and abandonment (P&A). This technology can mitigate risks, such as thermo-mechanical failure and fluid migration, to help ensure long-term well stability.

WellLife software uses advanced FEA to analyze the casing, cement sheath, and formation information to determine the cement mechanical properties necessary for long-term integrity. During analysis, the cement sheath integrity is modeled as it is subjected to planned well operations. These operations, such as drilling, injection, production, fracturing, and abandonment, can impart temperature and/or pressure loads that result in stress on the cement sheath, which can lead to potential cement failure.

The software evaluates the failure risk in multiple modes that might occur throughout the life of the well. Modes of failure for the wellbore components (i.e., cement sheath, casing, and formation) include compression, tension, debonding, casing plasticity, and formation shear. When the most likely failure mode is understood, Halliburton engineers can tailor the exact mechanical properties for the unique operations the annular barrier will experience throughout the production and abandonment phases of the well.

Modeling feature

Modeling feature

Modeling feature

Modeling feature

Evaluating LCM selection and concentration for optimal passage, suspendability, and transport.

Lost Circulation Wizard™ software allows Halliburton technical professionals to predict the optimal LCM/fluid package to mitigate losses during and after cement operations.

Tailored design decisions employed by machine learning to improve the probability of operational success.

Cementing barrier design and tailoring digital twin software that enables real-time job monitoring, evaluation, and instantaneous barrier validation.