Search

Search

Search

Search

27 zones isolated and fracked in ERD wellbore

Download PDFUnconventionals

Selectively isolate zones to reach maximum efficiency in an unconventional well

Canada

The operator needed to isolate and selectively fracture 27 specific zones

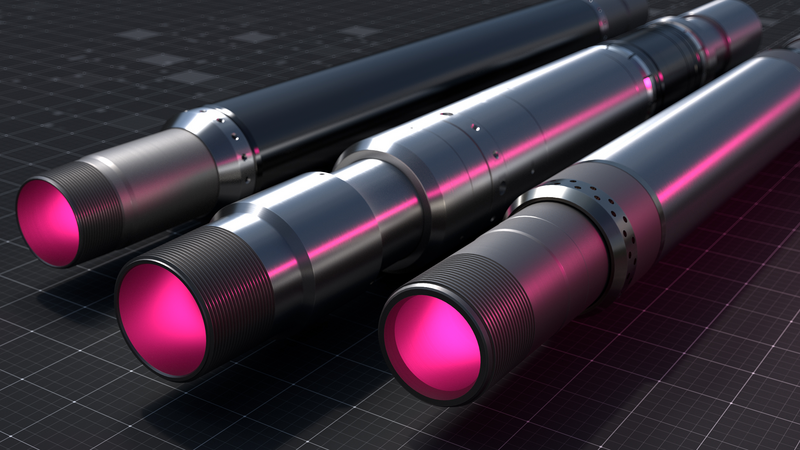

ZoneGuard openhole packers and RapidStage frac sleeves helped an operator in Canada to reach maximum efficiency in their unconventional well by selectively isolating and stimulating 27 zones. These high-pressure, capable packers were able to reduce risk and cost, giving the operator peace of mind and money in their pockets.

An operator in Canada wanted to perform a multi-zone frac job to optimize well production in their unconventional wellbore. The desire was to isolate and selectively stimulate 27 zones in the lateral section of the wellbore in the most efficient manner possible. They were looking for a cost-effective solution for this challenge, in order to help lower the cost of producing each barrel of oil.

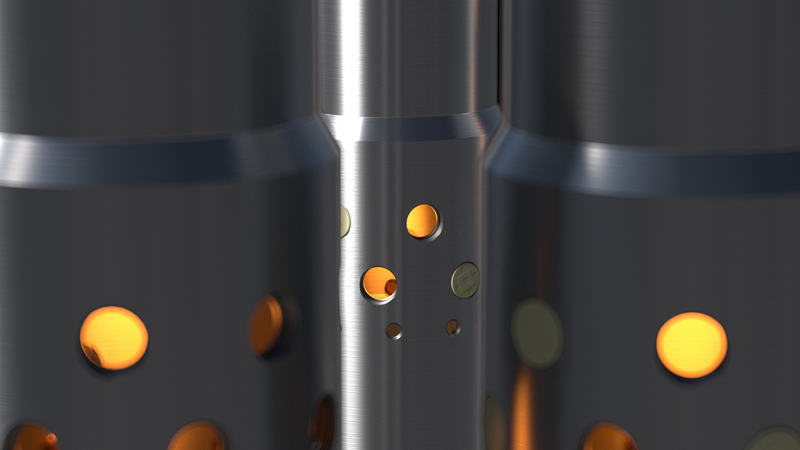

Halliburton proposed using hydraulically-set ZoneGuard SR packers and RapidStage single-entry frac sleeves to enhance the efficiency of the completion, saving time as well as ensuring the solution was cost effective. The ZoneGuard SR packer would provide effective annular isolation of the 27 target frac stages.

RapidStage frac sleeves stimulate each stage through the use of a ball-drop opening process, imparting maximum time-savings. Additionally, the ability to run, set, and isolate each zone in one trip reduces rig time while running the completion and the continuous pumping operations enabled by the RapidStage sleeve.

The instant isolation achieved by using ZoneGuard SR packers allowed the well to be stimulated immediately after the rig was released, further enhancing the cost-effectiveness of the solution.

feet total depth

psi pressure encountered

ZoneGuard SR packers run and set in one trip

The multistage frac completion was run to depth successfully. The ZoneGuard SR packer’s short compact design was an essential feature in helping to deploy the completion to depth with decreased risk. Once the completion was on depth, the ZoneGuard SR packers were immediately set and the rig released from location. The stimulation crew was then able to quickly move in so that fracking could begin. The packer’s high-pressure capability provided the isolation needed for effective fracture placement. All 27 zones were effectively isolated, and the target zones stimulated without incident.

Highlights of the job included:

Openhole Isolation

The Halliburton ZoneGuard SR (Short Radius) openhole packer is a versatile solution that helps enable effective annular zonal isolation in a wide range of oilfield applications.

Download Data Sheet

Expanding, swellable, mechanical zonal isolation systems provide unsurpassed sealing capabilities to help reduce well construction costs.

Maximize production with multistage fracturing completion systems that help reduce stimulation time and offer selective zonal treatment.