Search

Search

Search

Search

Reduced interventions significantly increases operational efficiency

Download PDFDeep Water

Set a production packer and provide dual barriers with minimal intervention

North Sea

North Sea, operator wanted to eliminate interventions during completion installation to reduce associated rig time. Halliburton proposed using the eRED®-LV™ remotely operated barrier valve and the EV0-RED™ bridge plug to reduce intervention runs and increase operational efficiency.

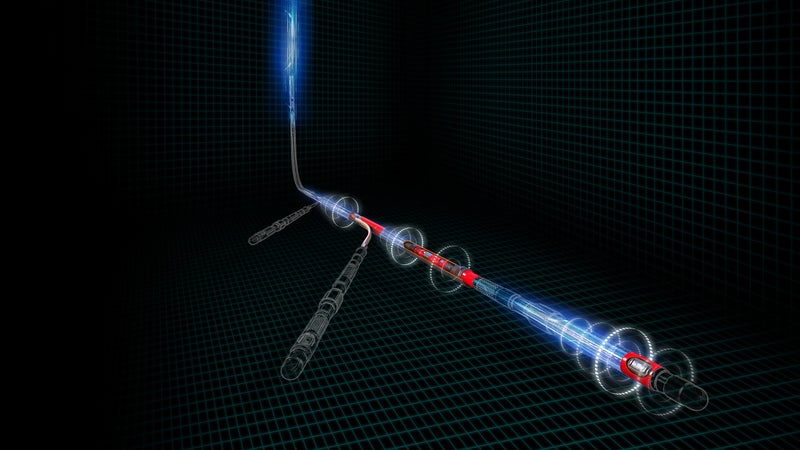

Following Halliburton recommendations, the operator elected to run the eRED-LV valve as a production packer-setting device and deep-set barrier, permanently installed as part of the completion tubing. The EV0-RED bridge plug was used as a preinstalled shallow-set barrier, which would later be retrieved from the well via slickline. The valve and the plug use onboard decision-making electronics that monitor well conditions and are programmed to open or close whenever a specified condition (known as a trigger) is detected. This allowed the operator to remotely communicate with the tool from the surface using a combination of applied pressure commands and timers.

The combination of an eRED-LV valve to set the production packer and an EV0-RED plug to provide a dual barrier for blowout preventer (BOP) removal and tree installation, reduced the need for conventional intervention methods, which increased the efficiency of the operation and helped reduce the associated operational and health, safety, and environmental (HSE) risks.

The operator wanted to hydraulically set a production packer and provide dual well barriers with minimal intervention methods. The completion design had a limitation where only low pressure could be applied against the fluid loss device, hence the requirement for a separate packer-setting solution. The typical completion method would normally involve two full wireline rig ups/rig downs, ten shallow wireline runs and one deep wireline run.

Halliburton proposed using an eRED®-LV™ remotely operated isolation barrier valve, deployed in the open position, as the packer-setting device and deep-set barrier. Once the completion was landed and the hanger was tested, the eRED-LV valve was remotely closed to allow the production packer to be set. The eRED-LV valve was then remotely opened via pressure command to allow the annulus to be tested and reclosed to act as the deep-set barrier.

An EV0-RED™ bridge plug was proposed as the shallow-set barrier to allow removal of the BOP and christmas tree installation. The EV0-RED plug was preinstalled in a tubing joint onshore and deployed as part of the completion in the open position. Once the production packer was set and the eRED-LV valve reclosed, the EV0-RED plug was remotely closed via pressure command to act as the second barrier.

Upon installation of the christmas tree, the EV0-RED plug was remotely opened and subsequently pulled from the well via slickline. The eRED-LV valve and fluid loss device were then remotely opened via pressure commands to allow production to commence.

wireline rig up/rig down elimanted

shallow runs and one deep wireline run

Health, Safety, and Environmental (HSE) Issues

hours of Rig-Time Savings

Using the eRED-LV valve and EV0-RED bridge plug technology in this application saved the operator an estimated 59 hours of rig time compared to typical intervention methods. The remotely operated barrier valves eliminated one full wireline rig up/rig down, eight shallow runs and one deep wireline run. This technology also allowed the onboard wireline crew to perform simulated operations (SIMOPS) offline on another well, which reduced the scope of work on that well by a minimum of four days. The HSE risks involved with rigging up and running wireline were also eliminated in this case.

Halliburton intelligent completions technology help accelerate production and improve decision-making to increase ultimate recovery and maximize asset value

Halliburton eMotion valves provide interventionless remote control of hydraulically actuated completion equipment to eliminate multiple wireline runs.