Search

Search

Search

Search

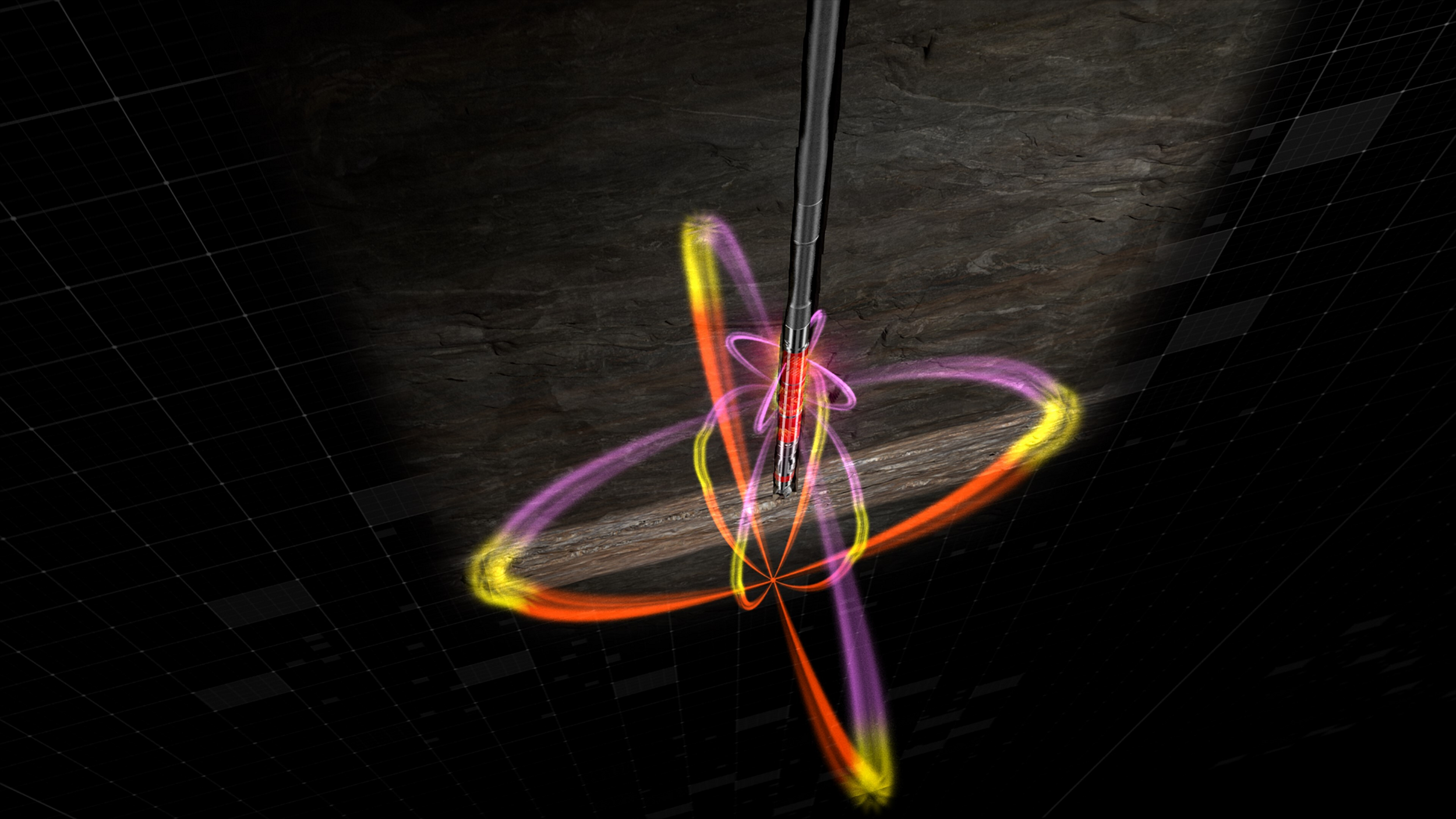

BrightStar® look-ahead resistivity reveals reservoir boundary

Download PDFMature Fields

Pick the coring point ahead of the bit

Norway

BrightStar look-ahead resistivity service used for:

A Norwegian oil exploration and development company was planning to drill a nearly vertical, 11-degree inclination well to assess a reservoir in the Norwegian Continental Shelf. Coring across the reservoir boundary was required, necessitating a geostopping operation on the drilling run prior to commencement of core sampling. The previous section was cased off at an estimated 58 m MD above the top reservoir.

Halliburton Sperry Drilling recommended the implementation of our newest logging-while-drilling (LWD) electromagnetic (EM) sensor technology, BrightStar look-ahead resistivity service, to illuminate the reservoir boundary.

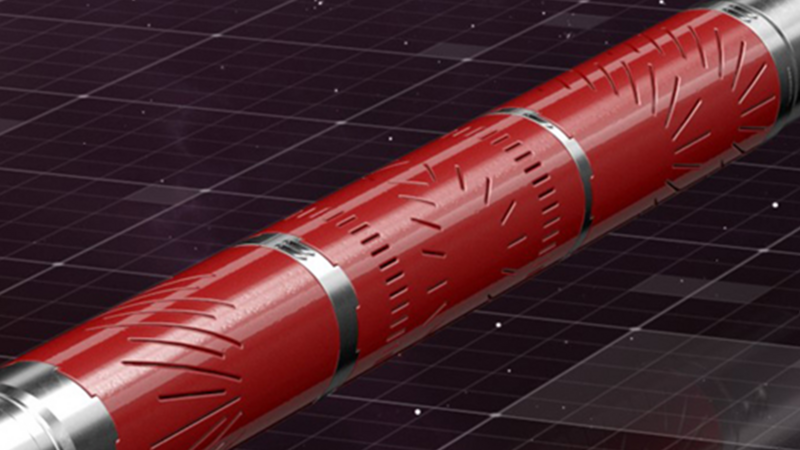

When deploying new technology, establishing the confidence in delivering the expected results is vital. The BrightStar EM antenna-type sensors were run alongside existing LWD services with the ultra-deep transmitter being placed 9 m behind the bit rather than the optimal 3-m placement, requiring “very early” detection of the top of the reservoir.

The close proximity of the casing shoe above, a cause of concern for interference with the EM signals, further limited the open hole section in which to establish the background resistivity and then identify the reservoir below.

LWD EM sensor for RT anisotropy & dip angle

TVD below - reservoir top picked successfully

The operator agreed to run the BrightStar service with the transmitter-to-receiver spacing optimized for early reservoir boundary detection, while limiting interference from the existing casing. To ensure an early warning of the reservoir top, pre-well modeling was performed to confirm the tool’s ability to detect the top of the reservoir up to 24 m below the transmitter. Assessment of offset data also indicated the look-ahead inversion could be supported by correlation against gamma ray and near-bit resistivty logs. This provided confidence in geostopping before penetrating the reservoir.

This project deployed the first LWD EM sensor equipped with a fully triaxial, co-located, tilted antenna structure for real-time anistrophy and dip angle determination. The tool, along with a unique processing scheme, enables the determination of horizontal and vertical resistivity, as well as the dip angle and the azimuth of the formation, while drilling in real time. The co-located sensor design is capable of acquiring multi-component signals that are sensitive to formation anisotropy and structural dip in wells at any orientation.

Pre-well modeling indicated that with the expected thickness and resistivity of the reservoir, boundaries could potentially be detected up to 24 m below. The reservoir resistivity and thickness were much less than anticipated. However, the boundary was still detetcted prior to being penetrated by the bit with confidence 12 m below the transmitter and ahead of the bit. After a successful coring run, the reservoir top was confirmed at the depth predicted by the BrightStar LWD data.

This project demonstrates the reliability of the BrightStar look-ahead resistivity service to accurately detect the top of a reservoir before it is penetrated. Coring was successfully conducted, and casing was set at an optimal distance above or within the target formation. Despite the promixity to casing that limited the transmitter-to-reciever spacing and a lower resistivity contrast than anticipated, the results were outstanding - poviding high confidence in the deployment of the BrightStar service for use in other operations.

Look-ahead resistivity measurements revealing structure and fluid boundaries to enable proactive drilling decisions.

Fully digital and web-enabled to monitor and control drilling and logging operations from anywhere.