Search

Search

Search

Search

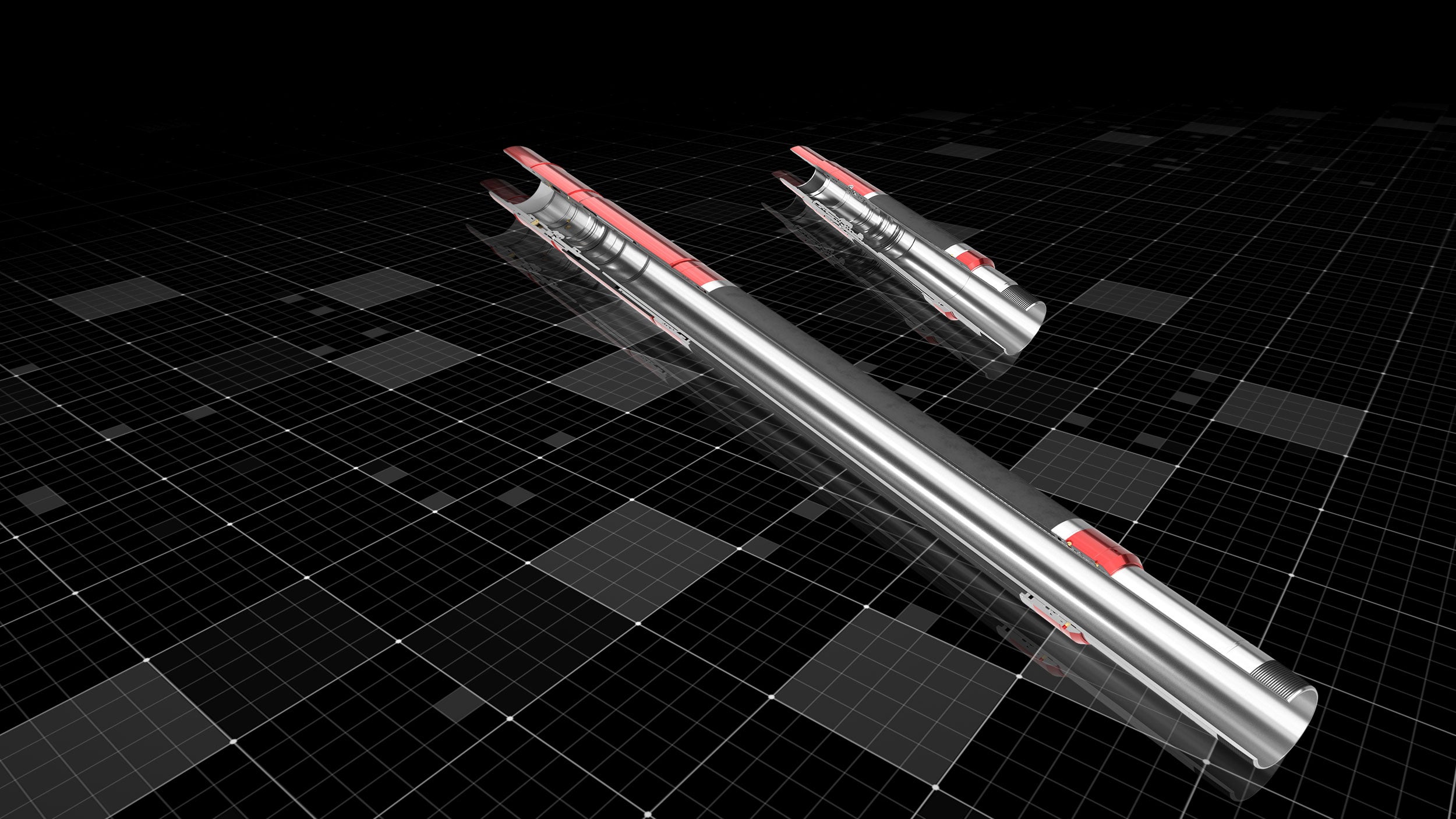

ESIPC™ packer collar and MSIPC packer collar help achieve top of cement and ensure barrier dependability

Download PDFMature Fields

Compromised zonal isolation attributed to losses in intermediate casing string

Iraq

Operators have waged a decade-long battle against losses in southern Iraq. The formation is interbedded with dolomite and limestone, which causes large vuggy depletions that can lead to losses while drilling. Attempts to use lost-circulation materials to overcome such losses were largely unsuccessful because of concentration limits pumping through float equipment. A narrow pore pressure and fracture gradient present additional challenges to zonal isolation during cement operations.

The paramount requirement for zonal isolation is to establish a primary well barrier element in the annulus to prevent unwanted fluid flow from permeable zones. This flow can occur either to the surface, which results in sustained casing pressure, or between distinct producing zones in the form of crossflow.

The added complexity of severe mud losses while drilling intermediate sections made this objective more challenging. Precise equivalent circulating density management during cement operations was previously used to reduce excessive hydrostatic pressure on the formation but was not an effective solution. Thus, a robust and sustainable barrier placed from the intermediate section to the surface was necessary to provide zonal isolation for the life of the well.

Halliburton implemented multiple-stage cement tools with integral packers, ESIPC™ and MSIPC packer collars, to provide mechanical support to maintain hydrostatic head during the second cementing stage and ensure a successful cement operation. This approach eliminated the need for multiple trips, prevented the loss of mud and cement material, and reduced expensive remediation efforts.

The integral inflation system through the multi-stage cementer enabled fast and reliable deployment of the packer and second-stage cement with a single pressure trigger instead of three. The packer element supported the hydrostatic burden of the long fluid column pumped during the second cementing stage to protect the formation and ensure good cement coverage to the surface.

To further enhance zonal isolation, bottom and top plugs were used in the first and second stages to isolate fluids within the casing and ensure efficient cement placement.

Mechanical barriers deployed

Successful operations

Years of success

Over the past decade, operators in Iraq have used the ESIPC and MSIPC packer collars in over 450 successful intermediate casing operations. Bond logs from each well confirmed their effectiveness, significantly reducing the need for remedial work to ensure full annulus coverage by cement. Multiple operators in southern Iraq now prefer these packer collars for cementing similar wells.