Search

Search

Search

Search

Deep Water

Use mechanical wellbore cleaning tools in a high-angle deepwater well

Gulf of Mexico, USA

Perform an indirect displacement on a high-angle deepwater well, which included:

CleanWell® Solutions strategy, including the integrated use of:

An operator in the Gulf of Mexico planned an indirect displacement to seawater on its Auger platform while holding constant backpressure in a high-angle well (63° maximum deviation).

Electing to perform an indirect displacement (displacing the wellbore to seawater first, and then to completion brine) enabled the operator to perform a negative test after completing the seawater displacement. By bleeding off the backpressure that would be held during the displacement of synthetic-based mud (SBM) to seawater, the operator could chart and record a negative test prior to displacing the wellbore to completion brine. Performing the wellbore cleanout (WBCO) operations in this manner would eliminate the need to run a test packer in the well to perform the negative test, thus saving the operator an entire drillstring trip.

This was the first indirect displacement to be executed on the Auger tension leg platform (TLP).

The indirect displacement method presented two major challenges that could affect the success of the WBCO operation:

The Baroid completion fluids team prepared a detailed displacement procedure based on the CleanWell® Solutions strategy. This included the integrated use of BaraKlean® spacer trains, BaraClear™ brine filtration services, and CleanWell® mechanical wellbore cleaning tools.

BaraKlean spacer trains formulated with BaraKlean-648 casing cleaner were used in both the SBM-to-seawater displacement and the seawater-to-CaBr2/CaCl2 brine displacement.

During the SBM-to-seawater displacement, a full BaraKlean spacer train was used (base oil spacer, weighted spacer, cleaning spacer, and high-vis spacer). No pipe rotation or reciprocation could be performed during this phase of the operations due to the rig equipment limitations. Initial seawater returns to surface had a solids content of 0.1 percent v/v.

After completing the SBM-to-seawater displacement, the first CleanWell® Drill Tech® assembly was short-tripped to surface. As expected, a residual film of SBM was seen on the scraper assembly – resulting from the inability to rotate and reciprocate during the displacement.

The WBCO assembly was tripped back in the hole to over 21,000 feet (6,401 meters) measured depth (MD) in preparation for the seawater-to-CaBr2/CaCl2 displacement.

The BaraClear filtration system was used to efficiently filter the brine during the seawater-to-brine displacement. The 1,600-square-foot (149-square-meter) filter press was equipped with 4-inch hoses to provide the filtration rates required to maintain specified circulation rates during the wellbore cleanup operations.

Tests on the brine returns confirmed a desirable final turbidity measurement of 23 NTU and < 0.025 percent v/v solids content after completing approximately two full wellbore circulations in 4.5 hours.

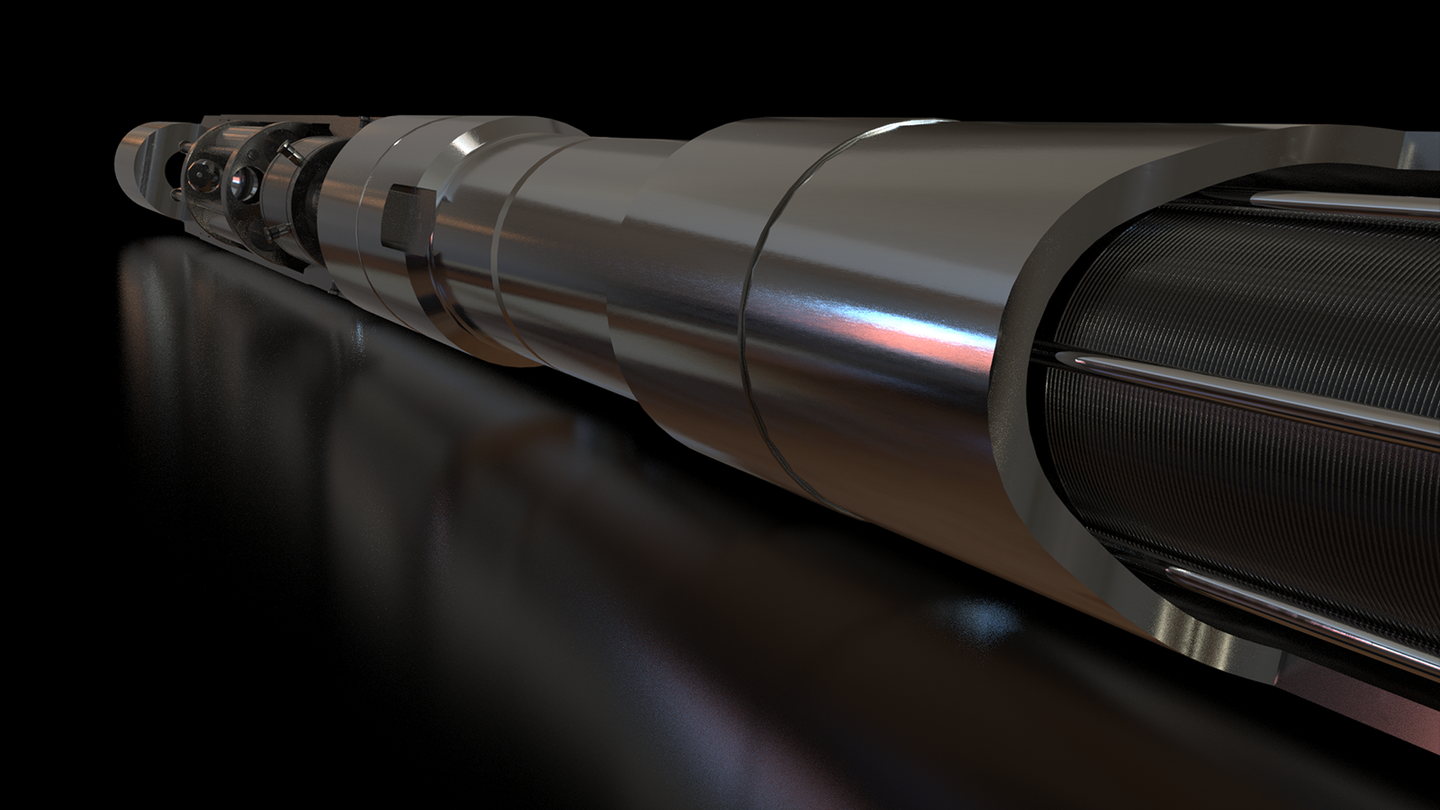

CleanWell WBCO tools provided additional mechanical cleaning of the casing walls and captured residual debris.

Cleanout tools included the following:

During the seawater-to-brine displacement, a second BaraKlean spacer train (high-vis spacer, cleaning spacer, high-vis spacer) was pumped to remove all residual SBM on the casing walls and drillpipe. The drillpipe was rotated and reciprocated during this displacement, which allowed the CleanWell WBCO tools to perform mechanical cleaning on the casing walls.

Hours of rig-time savings

USD saved

The coordination of the customized spacer trains, high-rate filtration, and WBCO tools allowed the operator to successfully displace the high-angle wellbore from SBM to completion fluid with limited drillpipe rotation or reciprocation, and restricted circulating rates.

This eliminated the need to perform a separate drillpipe trip to conduct a negative test, saving approximately 24 hours of rig time valued at USD 190,000.

When suitable for the operations and wellbore characteristics, this displacement method will be duplicated on future wells for this rig and operator.

Reduce well construction costs with the latest-generation of filtration services, wellbore cleanup fluids, mechanical wellbore cleaning tools, and optimized software modeling.