Search

Search

Search

Search

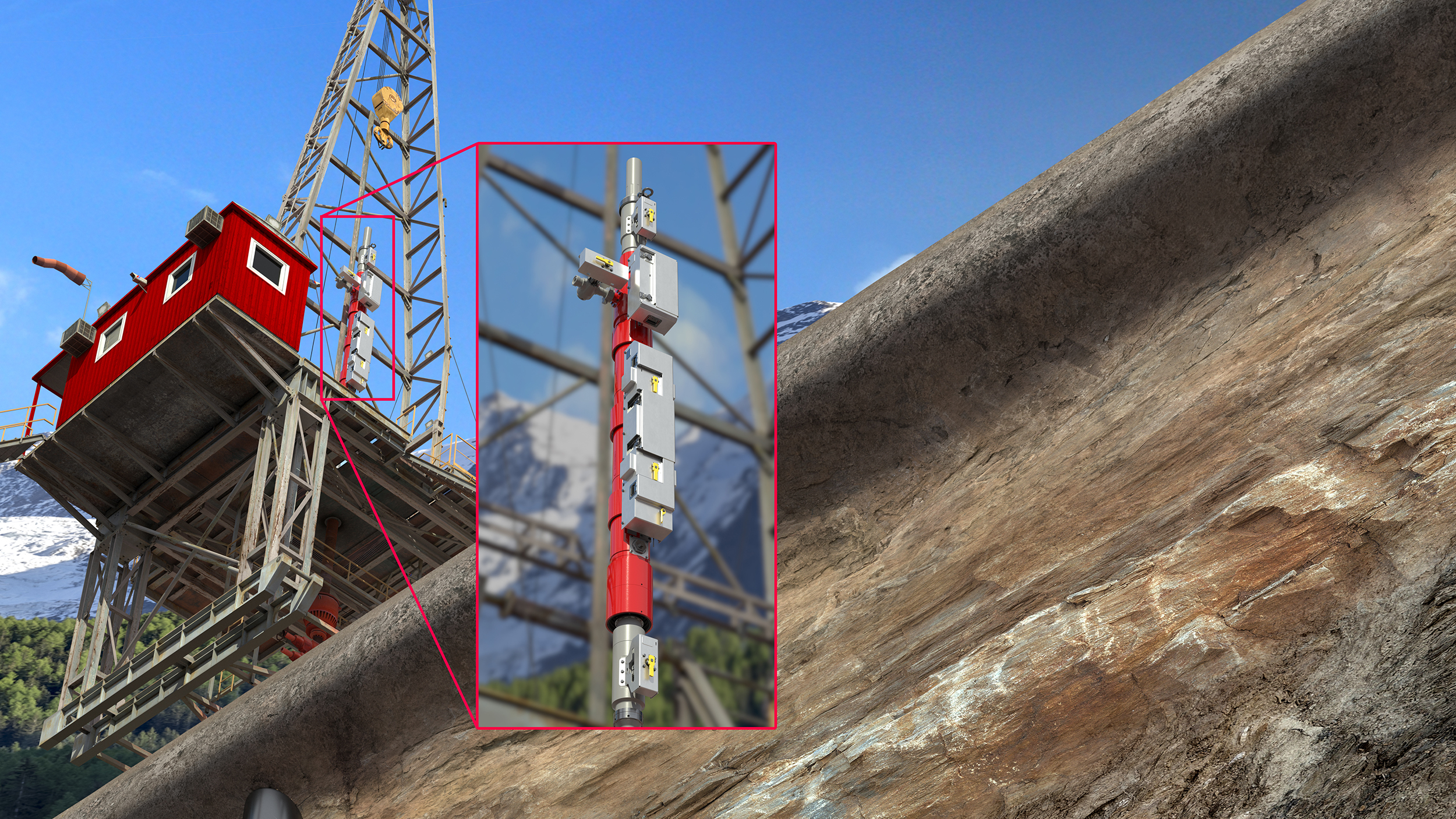

Rotation from Commander™ full bore cement head helps eliminate visual channels

Download PDFUnconventionals

Reduce annular pressures and improve bond logs for SRC Energy

Denver-Julesburg Basin, Colorado

SRC Energy was looking to develop new annular pressure mitigation plans to address changing requirements in the Denver-Julesburg Basin in Colorado. The Colorado Oil and Gas Conservation Commission had recently released a notice to operators regarding new regulations on the amount of annular pressure that is acceptable prior to and after stimulation before a well can be produced. Outlining the well challenges and aligning to the state regulations, SRC and Halliburton worked together to identify an integrated solution including three key cementing products (LockCem™ cement, tailored with latex and foam cementing technologies) and the new Commander™ Full Bore cement head in order to reduce annular pressures and improve bond logs.

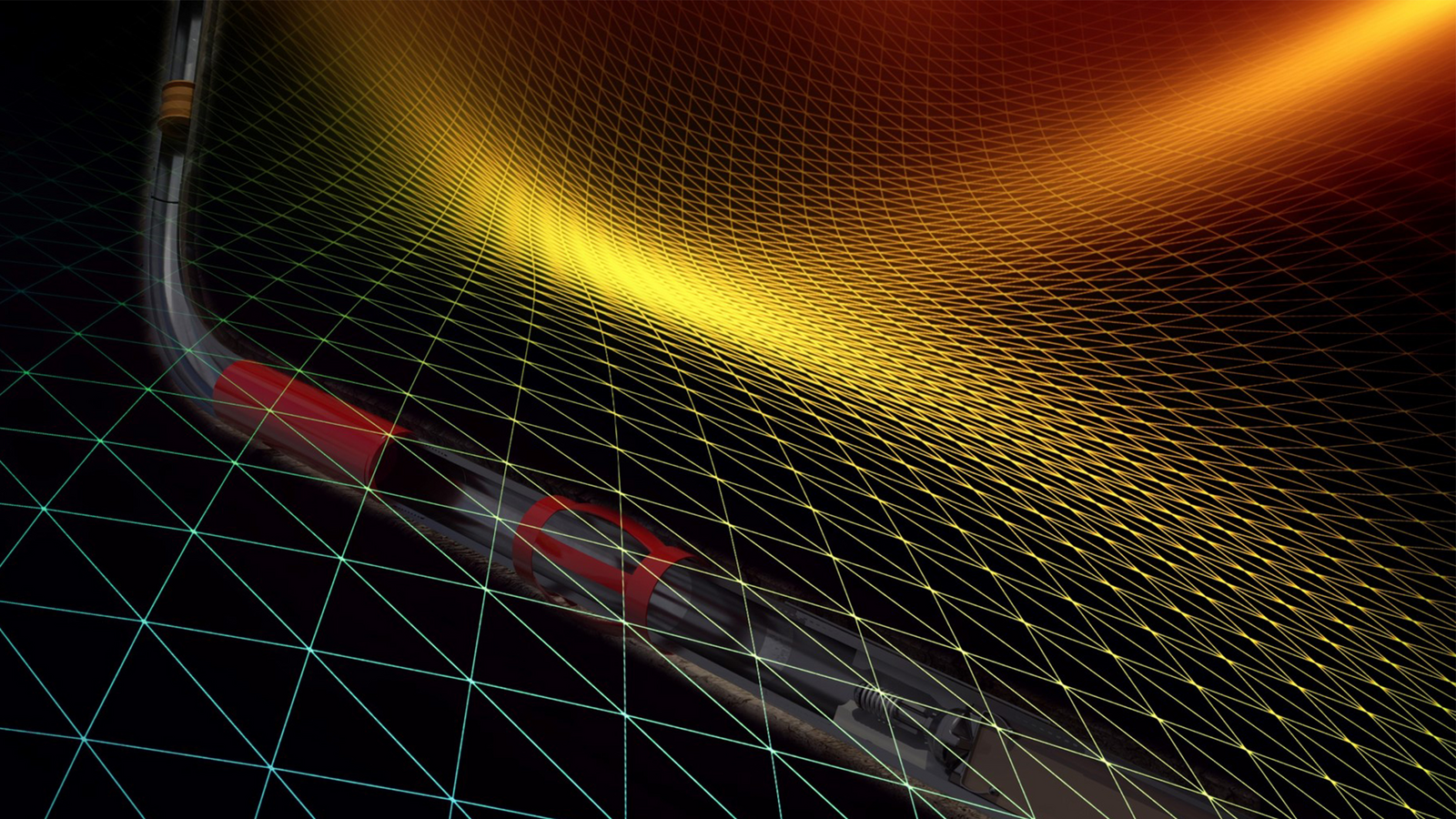

SRC wanted to reduce uncertainty and the risk of channeling by adjusting their operational program to include new slurries and pipe rotation as best practices to address any gas migration and annular pressure issues moving forward. SRC and Halliburton estimated that proper mitigation of these issues would help improve zonal isolation.

Halliburton recommended its LockCem™ cement, along with latex and foam cementing technologies, and the Commander FB top-drive cementing head. For this latter tool, rotation would be run at 30 rpm for the entire cementing job, with a maximum torque of 29,000 ft-lb.

The rotation showed a drastic benefit in the horizontal section by eliminating visual channels. CAST-M™ bond logs were run in the horizontal section to determine the effectiveness of the rotation. The Halliburton solution ultimately provided significant improvements in zonal isolation.

Enabling rotation and reciprocation to improve cement coverage to reduce communication between frac stages and maximize asset value.

Meet the unique pressure, temperature, and property demands of each well.

Halliburton casing solutions help run and land casing to depth, ensure proper centralization, and achieve long-term zonal isolation.