Search

Search

Search

Search

Innovative technology sets new benchmarks in deepwater coring operations

Download PDFDeepwater

Perform coring in exploration wells in deepwater

India

An operator planned its first drilling operation in the offshore deepwater region located in India. The goal was to extract core from vertical exploration wells at the greatest depth in its history in India.

Previously, the operator had achieved poor recovery rates of 0 to 50% in deepwater coring operations within the unconsolidated/interbedded formations in the eastern offshore area using a conventional coring system. Concerned about these results, the operator turned to Halliburton for alternative technology to meet its coring goals.

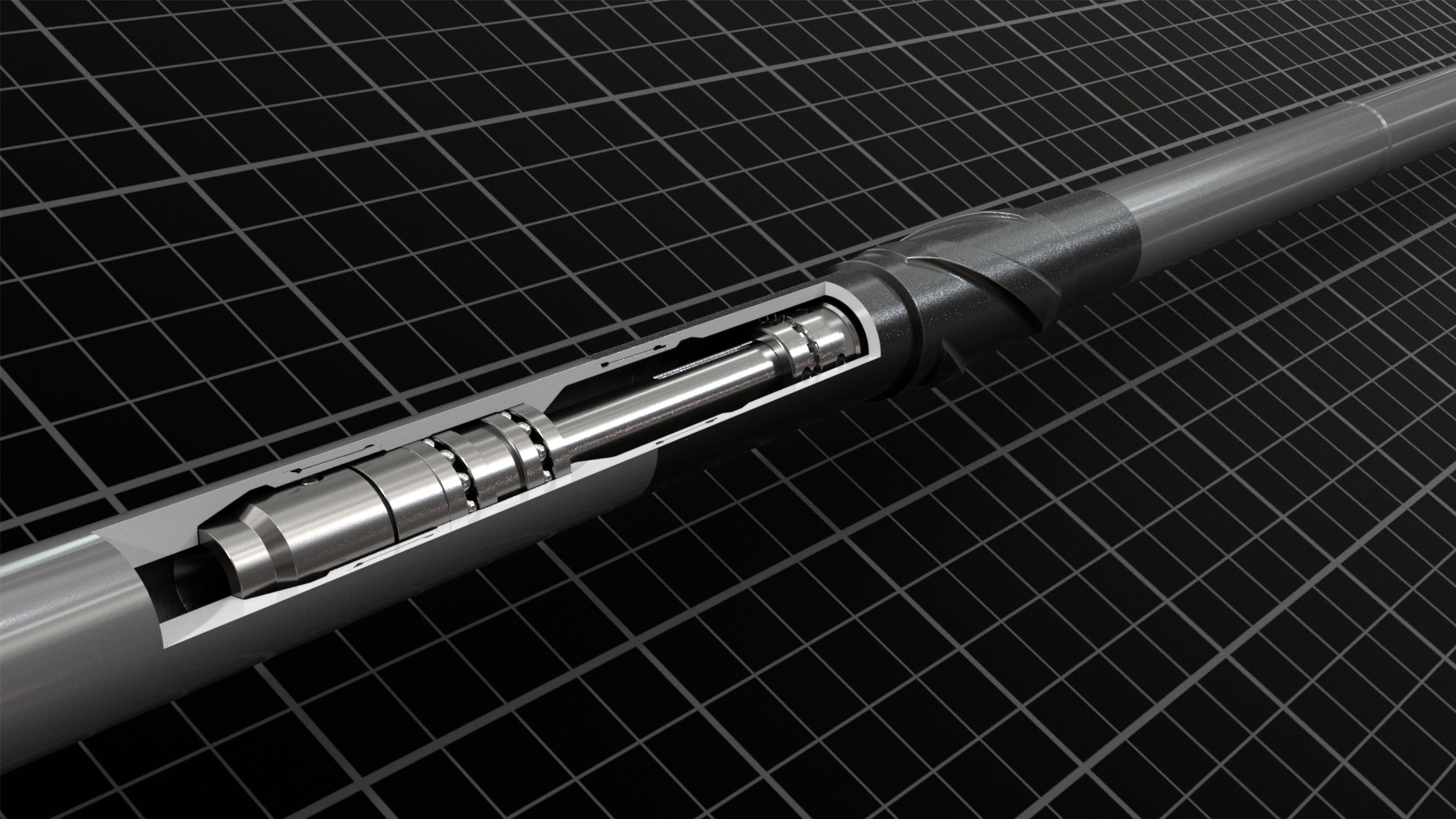

Halliburton analyzed nearby well data and determined that the formation was interbedded with medium-hardness shale and unconsolidated sand. Based on this analysis, Halliburton recommended a 6 3/4 - x 4-in. RockStrong FCS™ coring system equipped with the latest polycrystalline diamond compact (PDC) core head design. The anti-jamming swivel assembly was chosen to minimize vibration while cutting through transition zones with the FCS™ full closure system assembly to capture the unconsolidated formation at the bottom.

Meters cored

Runs

Recovery

Halliburton extracted 90 m of core from this well in approximately five runs (12 1/4-in. and 8 1/2-in. sections combined) at a 100% recovery rate, with no safety issues or nonproductive time. The core was extracted from over 6,000 m, the deepest target cored to date in this operator’s history. This operation set records for the deepest coring operation in India and deepwater applications. The RockStrong FCS™ coring system allowed the operator to perform full-scale studies on the recovered core. These studies helped identify potential production zones for DST operations.