Search

Search

Search

Search

Hedron® fixed cutter drill bit and motorized bottom hole assembly optimizes directional control and increases ROP by 120%

Download PDFUnconventionals

Drill curve and lateral in a single run

Abu Dhabi

Optimized directional control and maximized rate of penetration (ROP) are critical to directional drilling operations. PETRONAS Abu Dhabi sought Halliburton’s assistance in the 8.5 in. section to achieve optimal durability and steerability while drilling 5,873 ft through carbonate formation in an unconventional field.

Extended time spent landing in this section of the field can hinder lateral drilling, delay reaching total depth (TD), increase exposure to dysfunction while drilling, add wear to motors, and cause bit damage. Because motor failure is often the primary reason to pull out of hole, it is essential to maximize rotation time to preserve motor integrity in these challenging conditions.

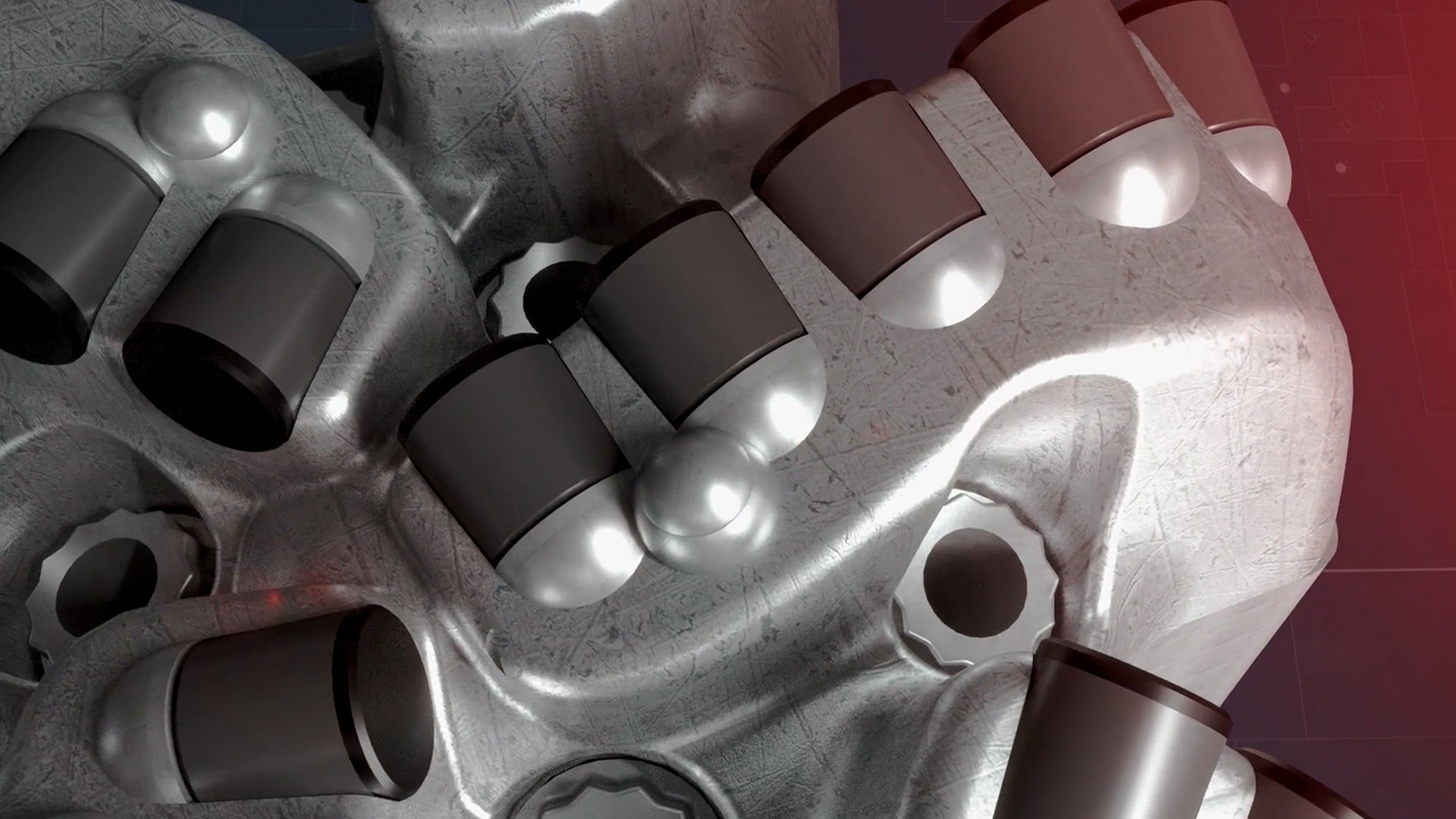

PETRONAS Abu Dhabi and Halliburton recommended a motorized bottom hole assembly and an 8.5-in. Hedron® HDi65RMKs directional bit equipped with Razor™ 4D-shaped cutters. This bit delivers drilling efficiency and directional control with the ability to geosteer in the lateral section. The technology enhances side-cutting performance through lateral forces applied by the bottom hole assembly (BHA) to improve steerability and stability when holding an angle.

Ft of lateral drilling

ROP improvement, a new benchmark

PETRONAS Abu Dhabi deployed the motorized BHA assembly to navigate the entire section. The curve was built with a maximum build rate of 5.5°/100 ft, followed by 5,873 ft of lateral drilling through the carbonate formation. The effective build rates achieved in the curve section aligned with PETRONAS Abu Dhabi requirements and improved ROP by 120%, a new benchmark in this field. The combination of technologies enhanced drilling performance and operational efficiency during this run. The bit reached section TD with an excellent dull grade and was retrieved at the surface in re-runable condition.

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.

Geometrix™ 4D-shaped cutters use different geometries to optimize drilling efficiency and durability.