Search

Search

Search

Search

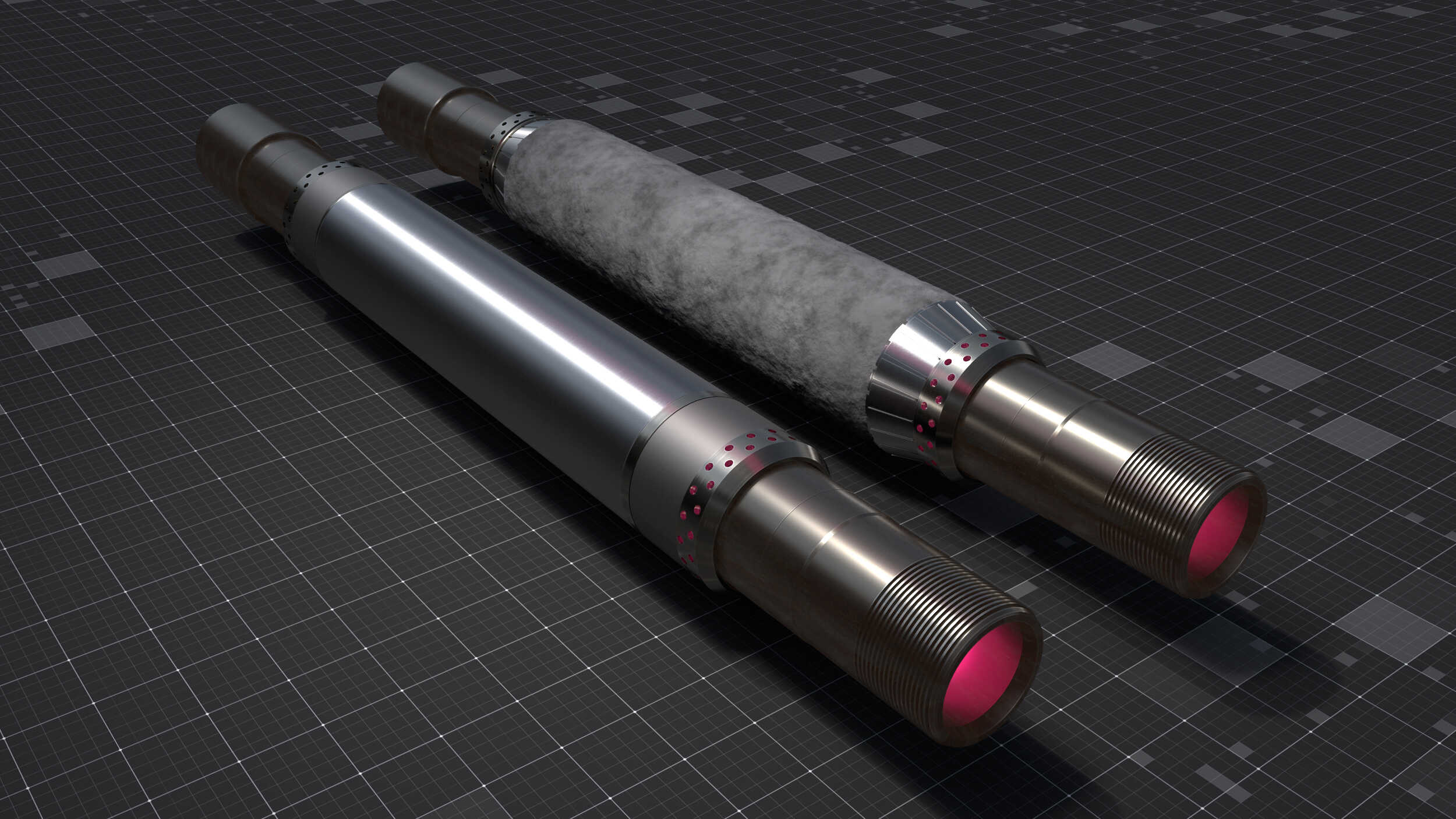

The Ovidius expanding isolation system is a new annular barrier packer that transforms from an engineered metal alloy to a rock-like material when it reacts with downhole fluids, creating a long-lasting seal for improved well integrity. Through innovations in Material Science, the Ovidius system packer can perform in extreme-temperature and pressure environments, providing superior isolation and anchoring for the life of the well. Robust, simple, and flexible, the Ovidius isolation system is ideal for cased-hole, openhole well isolation, high-pressure/high-temperature (HP/HT), and permanent plug and abandonment (P&A) operations with future applications in geothermal, multilateral, multistage fracturing, and recompletion operations.

Reaching target depth is the first measure of success for an annular barrier packer. With its slim OD, robust metal alloy construction, and no moving parts, the Ovidius isolation system simplifies run-in-hole operations and helps reduce risk. The ability to rotate and circulate as needed provides operators additional flexibility during deployment.

Solving the most difficult anchoring and isolation challenges extends beyond high differential pressure ratings. The modular slip-on design of the Ovidius system also simplifies logistics. In addition, the engineered metal alloy can be machined to work with uncommon casing geometries. Extensive laboratory testing has shown compatibility with common water-based fluid systems and resistance to H2S and CO2.

The Ovidius isolation system is capable of providing differential pressure ratings up to 17,500 psi. and anchoring forces in excess of 500,000 pounds. The packer does not rely on elastomeric seals; the engineered metal alloy becomes the seal. As a result, the Ovidius system has been proven to handle high-pressure and temperature swings without failure. With its high-expansion ratio and thermal stability rated up to 570°F, the Ovidius isolation system offers long-term sealing and anchoring stability in the most extreme downhole environments.