Search

Search

Search

Search

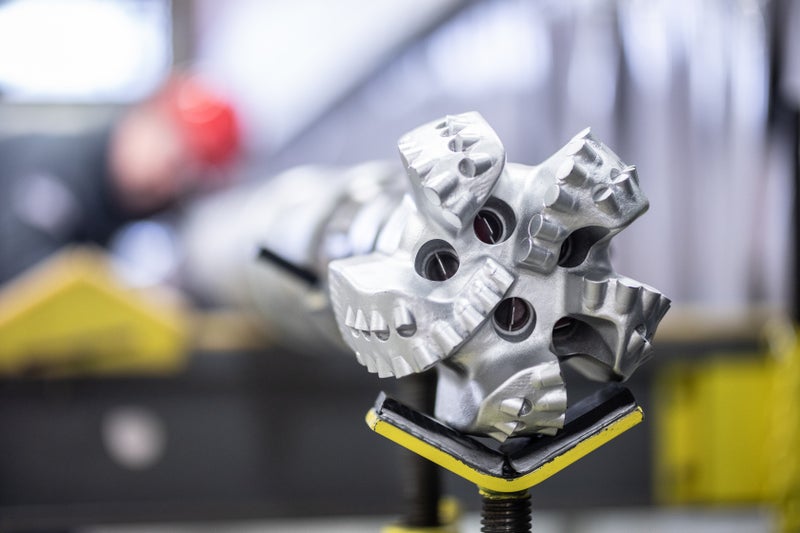

4¾-inch GABI™ motor and real-time gamma ray image helps drill to produce and delivers 99.3% in seam

Download PDFUnconventionals

Complex drilling operation in coal seams using improved geosteering technology

Queensland, Eastern Australia

Coal seams in eastern Australia have an average thickness of 2 m (6.5 ft.) total vertical depth (TVD), and are structurally complex with extensive faulting and changes to internal seam character, in addition to severe dip changes experienced while drilling the lateral of a horizontal well. Due to the complex nature of these seams, geosteering decisions have to be made promptly to avoid drilling out of seam.

A Queensland, Australia operator achieved its drilling target and remained in seam using real-time images from a 4¾-in. GABI™ motor from Halliburton, equipped with at-bit azimuthal gamma ray and inclination sensors for improved geosteering and optimum wellbore placement. Located approximately 3.5 m (11 ft) behind the drill bit, the GABI motor provided immediate feedback on directional trends and formation changes, enabling the fastest possible decision-making. Communication between the directional driller and geosteering specialist was also key to delivering well success.

The well was drilled 99.3% in seam, and a total lateral length of 1,243 m (4078 ft) MD. Total vertical depth at the heel was 480 m (1,574 ft) TVD, and at the toe was 450 m (1,476 ft) TVD, helping the operator drill to produce and maximize asset value.

To date, 80 wells have been geosteered with the GABI™ motor in Australia, for a total distance of 90,500 m (29,691 ft) at an average of 96% in seam.

In-seam drilling

Feet drilled over 80 wells

In-seam average for the 80 wells

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.

Halliburton drilling motors ensure faster drilling, reduced well time, and more accurate well placement in any basin application.

Directional drilling systems engineered to reduce well time and maximize reservoir contact from unconventional land to extended-reach deepwater drilling.

Halliburton has the expertise and downhole technology to ensure accurate well positioning at a precise location.