Search

Search

Search

Search

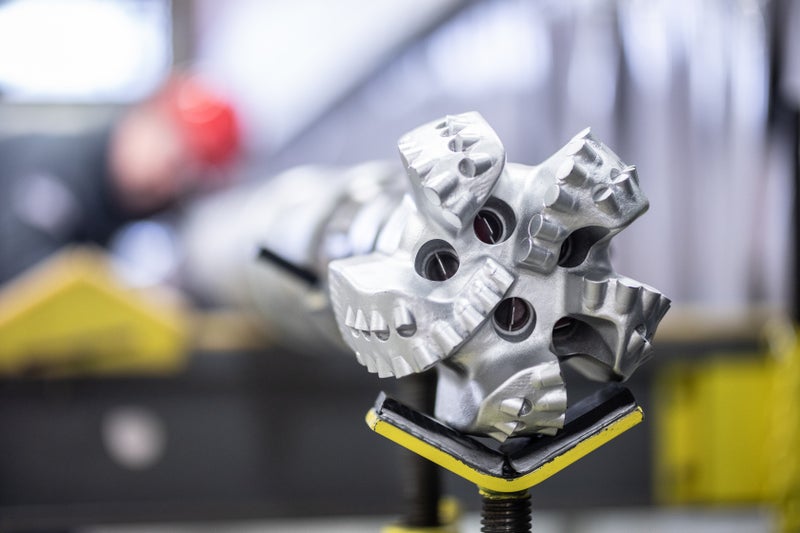

DrillDOC® drilling downhole optimization collar tool delivers real-time measurements from on-bit sensors

Download PDFDeep Water

Complete a challenging deep-water well through directional drilling optimization

Gulf of Mexico

An operator was finding it difficult to maintain downhole weight on their packers during challenging deep-water completions operations. High inclination wellbores and complex completions tool strings made it hard to determine if the previously modeled weight transfer was reflected downhole.

Expecting high weight and a large degree of buckling throughout the completions string, Halliburton Landmark and Sperry Drilling proposed a 4¾-in. DrillDOC® drilling downhole optimization collar tool for the job. The multiple on-bit sensors provided real-time measurements of various drilling parameters to help assess the actual downhole weight transfer.

Multiple slack off tests were conducted in synthetic-based mud (SBM) and in brine completions fluid, with both of the pumps on and off. These tests, conducted by the Solutions Engineering group of Sperry Drilling, delivered valuable friction factors for use on not only this project, but also applicable to similar completions operations.

Proper design of service and risk assessment contributed to the success of the run. The solution ended up reducing potential non-productive time (NPT) for this test well and throughout several completions wells, helping maximize asset value for the operator.

Halliburton offers a comprehensive portfolio of completion tool solutions that are purposed engineered to help customers maximize asset value.

The most advanced downhole solutions help better diagnose well conditions and deliver interventions with precision and confidence.

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.