Search

Search

Search

Search

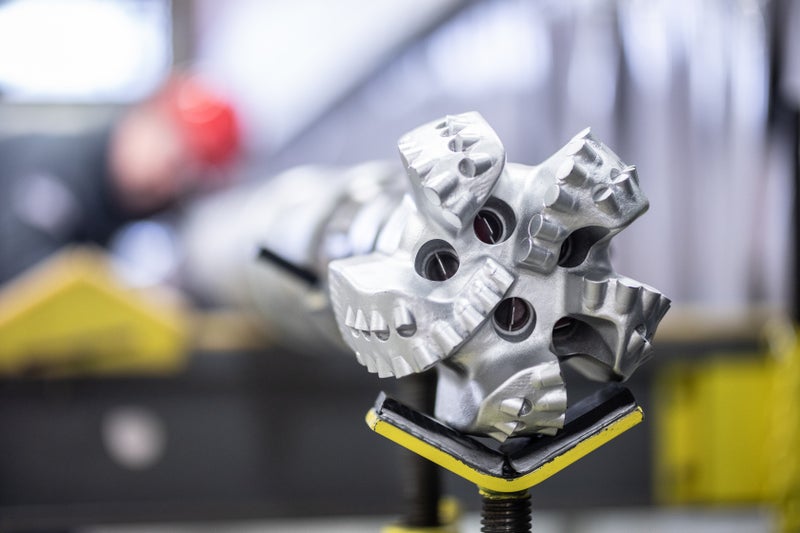

Customized BHA featuring Geo-Pilot® 9600 XL RSS helps maintain verticality and high ROP

Download PDFUnconventionals

Drill maintaining verticality and a high ROP for a batch of wells

Eastern Louisiana

An operator drilling a batch of wells in eastern Louisiana was attempting to decrease drilling time from 5 to 4 days in a particularly challenging 12¼-in. hole section. Previously, all the wells had been drilled with mud motor assemblies, achieving high rates of penetration (ROP) while rotating on bottom. However, the formation in this location created a build tendency in a northeastern direction that resulted in more frequent slides to maintain verticality. This sliding reduced ROP and made tool face control difficult in certain formations, requiring 5 days of drilling time.

Halliburton Sperry Drilling was brought in to help reduce well time, and facilitated a custom designed bottom hole assembly (BHA), including the Geo-Pilot® 9600 rotary steerable system (RSS), capable of addressing the issue of maintaining verticality—without sacrificing ROP. The complete BHA system was optimized to ensure proper hole cleaning at higher ROP.

Close collaboration between the Sperry Drilling team at a real-time operations center and the wellsite team was essential for maximizing ROP, while reducing connection times and mitigating vibration. The optimized Geo-Pilot BHA solution successfully drilled to produce the 12¼-in. section in just 3.7 days, exceeding the operator’s expectations and maximizing its asset value.

inch section drilled

days to complete drill

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.

The Halliburton Geo-Pilot® rotary steerable systems (RSS) is designed to deliver unprecedented speed and precise steering.