Search

Search

Search

Search

Survey management solutions help improve wellbore uncertainty

Download PDFMature Fields

Apply survey management to further refine the well plan ellipse

Gulf of Mexico

Inaccurate reporting from well planning database

Survey management processes significant improved wellbore uncertainty

An average of 600% reduction in ellipse of uncertainty values were applied to all audited wellbores

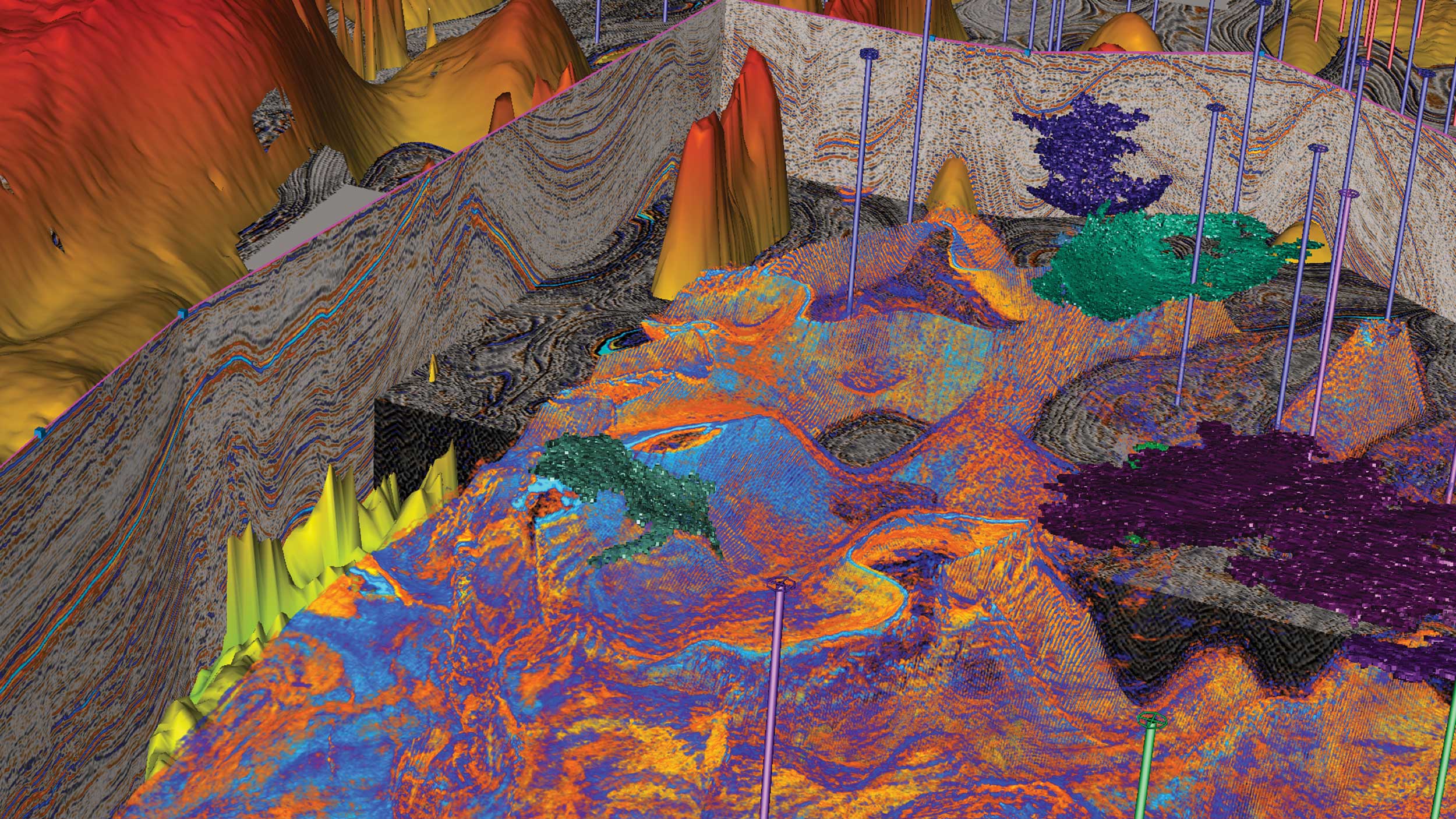

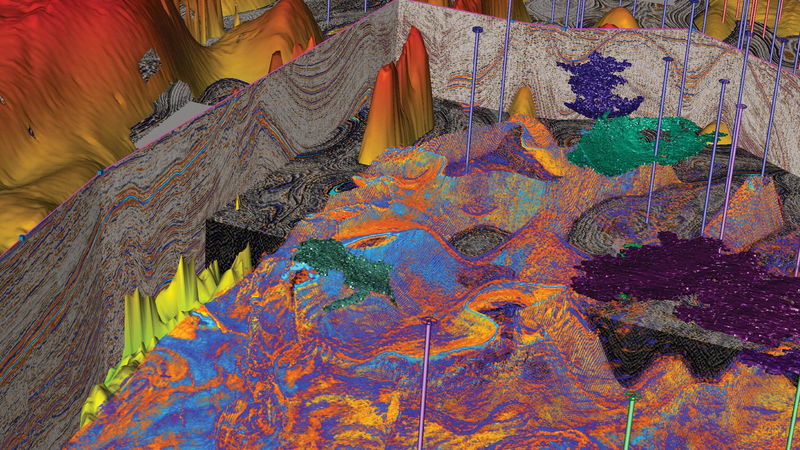

The COMPASS™ well planning database being used by an operator failed anticollision criteria on ongoing well plans due to unknown Instrument Performance Models (IPM) being applied to historic wellbores. As a result the wellbore uncertainty value applied was very conservative. To meet anti collision criteria, the customer challenged Halliburton Sperry Drilling to apply survey management services to further refine the well plan ellipse.

The Sperry Drilling Survey Management audit identified several opportunties to improve the wellbore uncertainty. The main priority was to assign proper IPMs to all wellbores and to assign at least one casing depth to each well to assist with generating proper anti-collision reports.

In addition, Sperry Drilling verified surface hole locations (SHLs) using the most current platform as-built. Many surveys had missing or incorrect data requiring analysis and manual updating before the data could be imported into the COMPASS database. Finally, the surveys were corrected from true to grid north. Survey information was then broken down into depths by survey instrument used, then finalized by comparing the Bottom Hole Location (BHL) with the survey documentation gathered from the well library and state/federal resources.

By implementing survey management processes, Sperry Drilling produced a significant improvement of wellbore uncertainty, which was applied to all of the corrected wellbores to meet anti collision criteria.

Upon completion of the database audit, an average of 600% reduction in ellipse of uncertainty values were applied to all audited wellbores. With verification and implementation of proper IPMs, a significant improvement of wellbore uncertainty was applied to all of the corrected wellbores to enable the customer to meet anti collision criteria on on-going well plans, maximizing asset value.

reduction in wellbore uncertainty

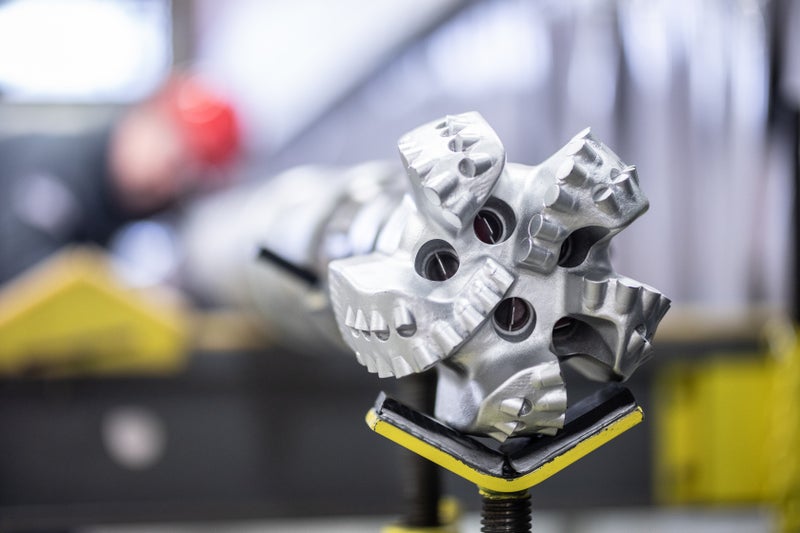

Using advanced real-time software to increase survey accuracy and reduce positional uncertainty.

The industry’s premier application for directional well path planning, survey data management, and anti-collision analysis.

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.