Search

Search

Search

Search

Mature Fields

Improve sustainability of hydrocarbon production from a mature field

Bahrah field

As part of Kuwait Oil Company’s (KOC’s) mature field strategy, there has been a focus on improving recovery of the maximum oil in place. One such field where there has been an increased focused is in the Bahrah field located in the Mauddud formation and is considered one of KOC’s most technically challenging fields. Historically, vertical wells have been employed with acid fracturing as the stimulation means with long-term hydrocarbon production supported by electric submersible pump (ESP) artificial lift. However, KOC recognized that this was not the most efficient way to complete wells in this field. Their focus was on maximizing production while lowering the cost per barrel of oil equivalent (BOE).

The target formation in the Bahrah field has a very low permeability of 0.5 mD to 1 mD and moderate to high hydrocarbon viscosity. Oil viscosities of 2 cp to 7 cp at 170°F (77°C) bottomhole conditions with 90 cp at surface conditions are common. These two primary drivers have resulted in unsustained hydrocarbon production over time. KOC was seeking improved long-term sustainable production while minimizing intervention events typically required in mature fields. The challenge was to overcome the low permeability through improved reservoir contact while managing the high hydrocarbon viscosity.

The first portion of the solution was drilling a horizontal lateral to maximize reservoir contact. The first trial well in the field incorporated a 3,000-foot (914-meter) lateral section. Now it was time to design the completion. Because of the low permeability of the formation, it was important to design a treatment that provided the greatest stimulated reservoir volume. Equally important was the ability to execute the completion timely with minimal complications or nonproductive time (NPT). Halliburton recommended the RapidStage® SE (single-entry) system.

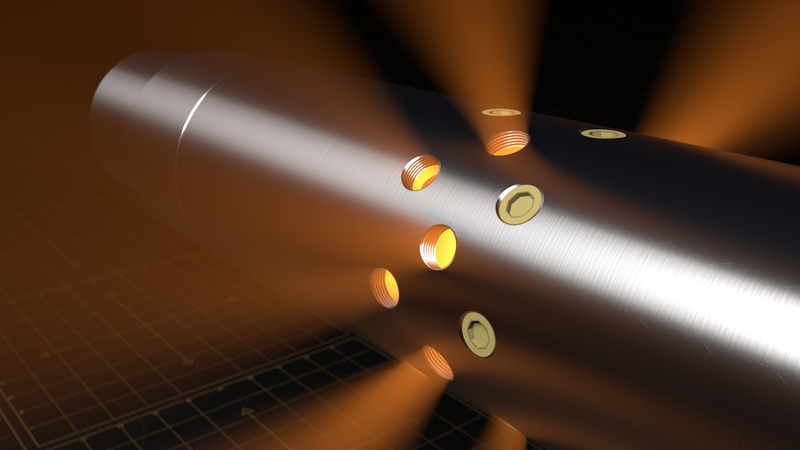

The RapidStage SE system optimizes the completion of multistage wellbores by enabling highly accurate placement of stimulation treatments without intervention. This helps ensure that the stimulation treatment covers the targeted areas in the wellbore and maximizes the stimulated reservoir area. For this well, the RapidStage SE sleeve system was utilized, allowing each individual sleeve to be opened during the treatment by a ball launched from surface.

ft lateral section

stage stimulation treatment

HSE or NPT

increased production as compared to offset wells

The initial plan for the seven-stage stimulation treatment was 14 days. The Halliburton team successfully executed the full seven stages in just six days – less than half of the original plan and with no health, safety, and environmental (HSE) issues or NPT. Further, hydrocarbon started to show on surface just hours into the initial flowback period. The well is now producing at 1,300 BOPD stabilized flow, 300 percent more than the standard vertical well completion methodology previously employed in the field.

Our commitment to delivering the lowest cost per BOE through surface efficiency, custom chemistry, and subsurface insight has changed KOC’s perception on multistage fracturing. With the right design and expertise to execute the treatment, the first multistage hydraulic fracturing treatment was completed, and has provided KOC with a game-changing field development strategy for future wells.

RapidStage systems optimize the completion of multistage wellbores by enabling highly accurate placement of stimulation treatments without intervention.

Download Data Sheet

RapidStage® frac sleeve systems optimize multistage completions by accurately placing stimulation treatments without intervention.