Search

Search

Search

Search

Real-time calculated GeoESP® virtual pump intake pressure (PIP) has less than 2% error versus downhole gauge readings.

Download PDF2023 Ruggero Bertani Endorsed Nominee

Geothermal

Geothermal wells in Germany are operated under strict monitoring regulations.

Germany

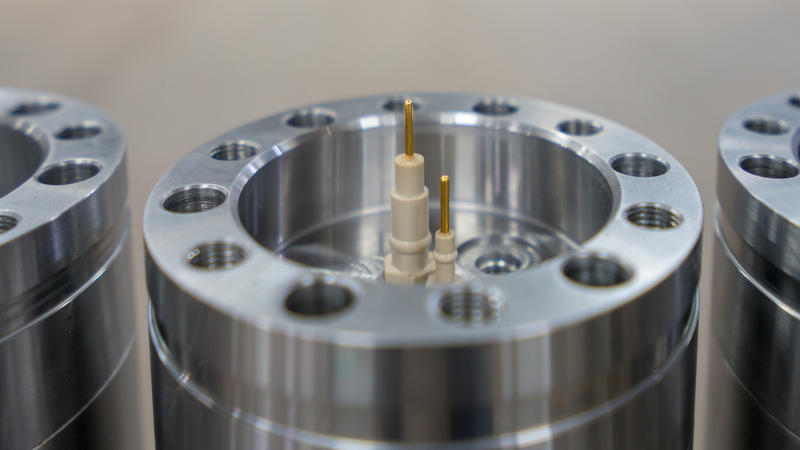

Intelevate Well Manager System Virtual PIP GeoESP® calculation presented in real time

German geothermal GeoESP wells provide energy for power generation and heating for homes and businesses. To ensure the highest level of safety for health and the environment, local authorities require meticulous monitoring and advanced tools to ensure efficient operations. Downhole gauges provide a wealth of information but are affected by harsh well conditions, including high wellbore temperatures and scale, which can affect performance or cause a short run life. When there are issues with a gauge, operators need an alternative that allows them to comply with government regulations without pulling the well to replace current downhole equipment.

PIP is a key diagnostic for the ESP system’s health and the wellbore’s integrity. Local governmental authorities require continuous real-time PIP values, but when the downhole gauge is faulty or fails, the well must be pulled unless there are alternatives. Hardware solutions on the surface can calculate PIP but are often expensive, require personnel to install, calibrate, and maintain, and can have a 20-30% error rate.

Summit ESP’s real-time calculated Virtual PIP App from the Intelevate Well Manager System’s industrial Internet of Things (IIOT) device considers well conditions, equipment specifications, and past performance to accurately calculate PIP with less than 2% error when compared with downhole gauge readings. Virtual PIP can also evaluate the current operating point and compare it to the best efficiency point.

With this innovative technology, geothermal operators can run ESPs longer without sensor readings and unplanned interventions; operators can plan equipment replacement with ample time to minimize unnecessary downtime. The technology can also be used with monitoring services to model well conditions and equipment performance to determine if proactive actions can be taken to improve uptime, equipment reliability, or increase production. Finally, and most importantly, with Intelevate Well Manager System’s Virtual PIP, operators can fulfill the governmental authorities’ requirements without extra hardware or maintenance expenses.

This project was selected as an endorsed nominee for the 2023 Ruggero Bertani European Geothermal Innovation Award, which celebrates outstanding contributions to the field of geothermal energy in the form of innovative products, scientific research, or project initiatives. The endorsed award nomination recognizes originality, innovation, reliability, and improvements in energy output.

Ruggero Bertani Endorsed Award Nomination

Calculated pump intake pressure (PIP) error

Incurred additional expenses

Governmental requirements fulfilled

Providing improved ESP system optimization and extensive customizable well monitoring to meet all your production needs.

Triton gauges from Summit ESP® are the next generation of downhole gauges with leading-edge technology that provide superior asset surveillance.