Search

Search

Search

Search

Extended-reach lateral solution allows operator to gain greater access to reservoir

Download PDFUnconventionals

Extend lateral length and reservoir contact to increase production of the wells

Vaca Muerta formation,

Halliburton proposed a semi-customized unconventional solution based on well conditions

Achieving more with less seems to be a common goal for many companies looking at optimization and efficiency these days. Exploration and production (E&P) companies are actively exploring new ways of effectively increasing contact with the reservoir in shale plays to increase ultimate recovery rates. Implementing “game-changer” technology has allowed operators to not only extend lateral length, but to also increase reservoir contact without the need for intervention – thus lowering costs per BOE. In certain geographical locations, these game-changer technologies can have a significant impact.

A major customer in the Vaca Muerta shale formation wanted to extend its lateral length and increase reservoir contact with the ultimate goal of increasing the cumulative production of its wells. Shale plays on North America land have seen trends with extending lateral lengths and in tightening cluster density. Historically, this customer was using only composite frac plugs in its completion design. Although efficient and low cost in nature, the composite plugs required intervention for their removal prior to placing wells on production. The proposed increase in lateral length challenged the capabilities of available coiled tubing to mill plugs. The lack of available coiled tubing in country, along with the limitations based on the size of coiled tubing available, challenged the customer to find a practical, validated solution. Seeking solutions, the customer looked to Halliburton for assistance.

Listening to the customer’s challenge and leveraging local experience and knowledge on dissolvable solutions, Halliburton proposed Illusion® dissolvable frac plugs for the extended-reach laterals and Fas Drill® Ultra frac plugs for the stages closer to the heel of the well. Working with Halliburton Production Solutions and the customer, we were able to properly assess the risks for determining an effective milling depth and to provide an appropriate solution.

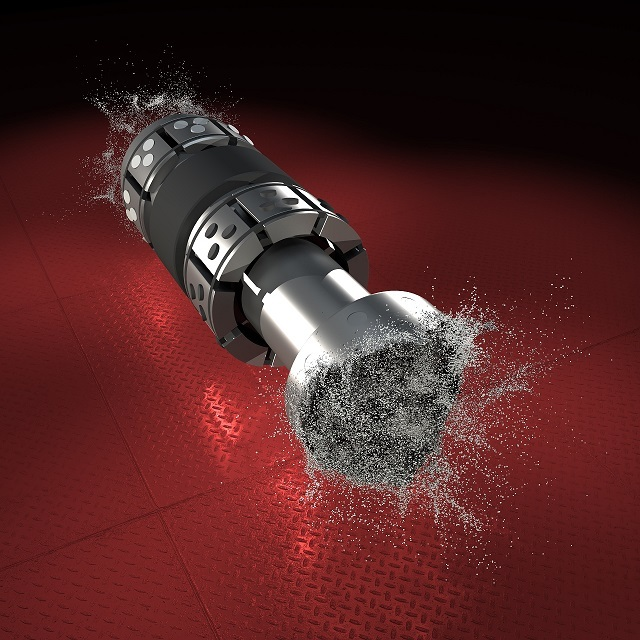

The Illusion plug’s design is based on the field-proven Fas Drill Ultra frac plug with pump-down rates that exceed that of many competitors. Our proprietary Illusion dissolvable metals have several variants that allow us to offer a semi-customized product solution based on well conditions. Our knowledge and experience as one of the pioneers in the region promoting dissolvable frac plugs allowed us to choose the optimal solution for this customer.

additional meters of reservoir access

Illusion plugs dissolved

Using Illusion dissolvable frac plugs, the customer effectively stimulated the reservoir along an additional 500 meters (1,640 feet) of lateral, and, in the stages closer to the heel of the well, the Fas Drill Ultra composite frac plugs were removed with minimal intervention effort. The well was then placed on production without additional intervention needs. The exposure time and salinity of the well at the toe was sufficient to ensure that all the Illusion plugs were dissolved. Coiled tubing was able to effectively mill the composite plugs, clean out the well, and place the well on production.

This high-performance frac plug provides zonal isolation of the wellbore during stimulation treatment and customized dissolution times

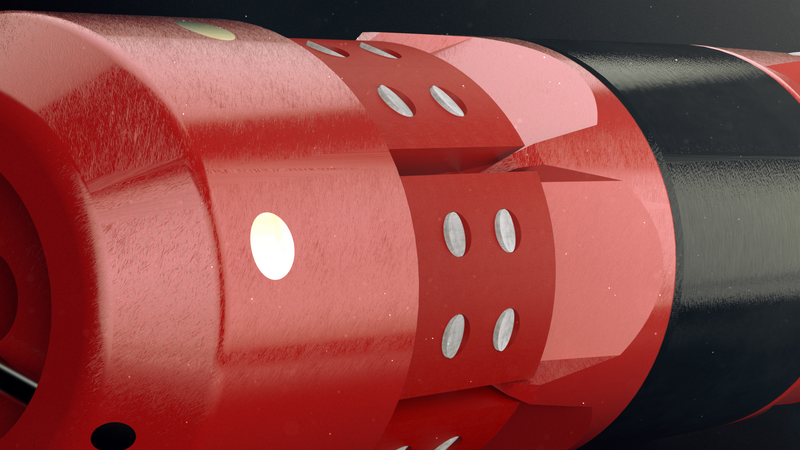

Fas Drill® Ultra frac plug is a composite drillable tool designed to provide zonal isolation of the wellbore between multistage stimulation treatments.