Search

Search

Search

Search

Geo-Pilot® RSS technology helps extend reservoir length 212% more than expected.

Download PDFMature Fields

Provide a complete, precise geosteering solution for a complex environment

Shallow Water, Gulf of Mexico

In the shallow-water shelf environment of the Gulf of Mexico (GOM), one of the fastest ways an operator can maximize asset value is to perform reentries on already existing wells, and then drill laterals through the reservoir section. A key to getting the most out of this approach is to extend the length of the pay zone. To do so in this complex environment requires precise geosteering, using the latest imaging technologies— ultra-deep resistivity tools and 3D inversion. A further difficulty for this particular operator was the application of such tools in a slim hole.

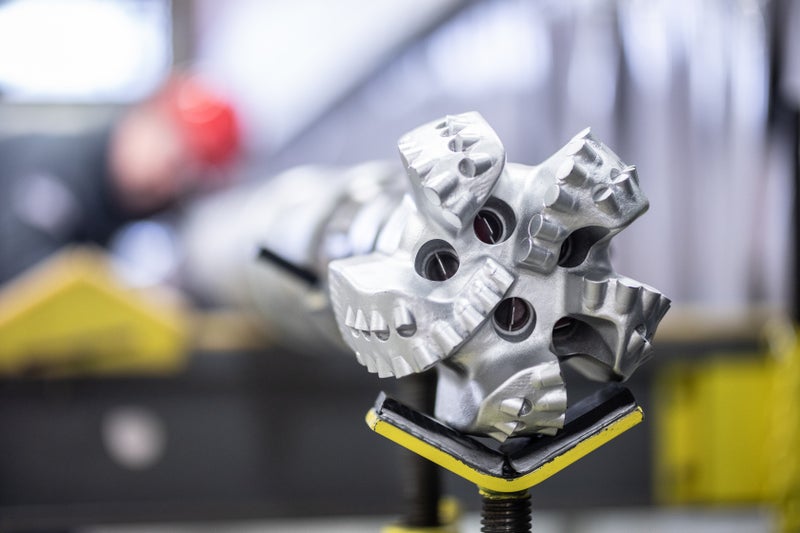

Sperry Drilling took on the challenge to provide a complete geosteering solution. Following a pre-well geosteering model, the curve was built and landed at 90° inclination 7 ft below the top targeted zone. A slim bottom hole assembly (BHA), consisting of a , was used to drill out and land the curve.

A super slim BHA, consisting of a 3-1/2 in. mud motor and 3-1/2 in. logging-while-drilling (LWD) tools—resistivity, gamma, and directional M/LWD collars—was critical to successfully geosteering through the tight reservoir.

Sperry Drilling delivered a reservoir section 212 percent longer than the operator expected, staying 100 percent in zone. LWD data shows geosteering enabled the BHA to remain 100 percent in the pay zone.

longer reservoir section delivered

in pay zone

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.

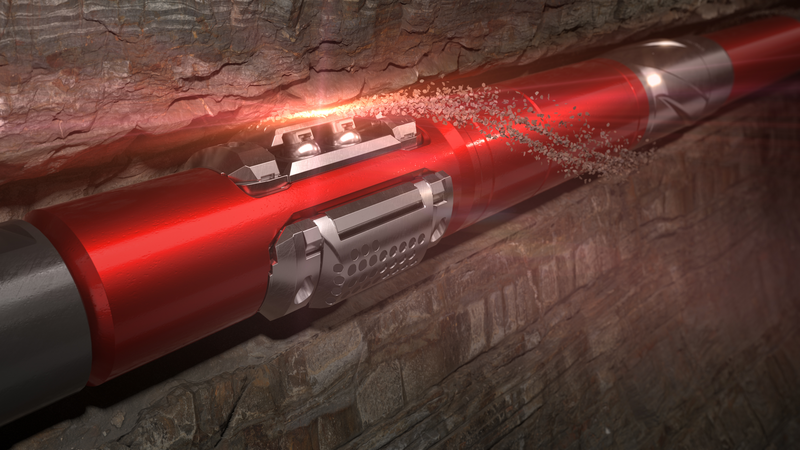

Halliburton rotary steerable systems are engineered with advanced technologies to reduce well time and accurately place well in reservoir.

The Halliburton Geo-Pilot® rotary steerable systems (RSS) is designed to deliver unprecedented speed and precise steering.