Search

Search

Search

Search

Simple and economical add-on service collects VSP data simultaneously alongside other CT fiber-optic diagnostic services

Download PDFUnconventionals

Collect high-quality DAS and VSP data during a conventional CT operation

Texas

Distributed Acoustic Sensing (DAS) is a rapidly evolving fiber-optic technology for monitoring cement curing, perforation performance, stimulation efficiency, production flow, and more recently for performing vertical seismic profiling (VSP). VSP data can be acquired and processed to determine velocity models that are used in surface seismic imaging for reservoir characterization or microseismic monitoring of hydraulic fracturing operations. Conventional VSP data acquisition via wireline-conveyed tools has limitations with well accessibility, especially when deploying into horizontal wellbores, and takes additional time during data acquisition. Fiber-optic cable conveyance by coiled tubing (CT) expands the opportunity for VSP data acquisition during planned CT interventions.

Halliburton sought to test whether a VSP of sufficient data quality could be collected during a conventional CT operation as traditionally it’s not an ideal environment for seismic data acquisition. Ideally, the fiber-optic cable would be coupled to or in direct contact with the formation. This would not be the case on this job, and the team would be operating in uncharted territory.

A FiberVSP™ service was run simultaneously with a Halliburton reservoir monitoring operation via a SPECTRUM® Real-Time CT unit. With a minimal footprint on the wellsite, Halliburton leveraged on the fiber-optic cable technology of the coiled tubing unit and used one of the fibers to easily collect data in significantly less time than it would have taken to acquire equivalent conventional geophone VSP data.

The FiberVSP™ data were recorded simultaneously alongside Distributed Temperature Sensing (DTS) data. The DTS data were acquired after water injection and shut-in during the warmback period of the well. The well is vertical for approximately 11,000 ft before turning horizontal for approximately 9,000 ft. The SPECTRUM CT-conveyed fiber was run in hole at an average velocity of 27 ft/min while pumping nitrogen. Real-time depth correlation was achieved by using a casing collar locator in the bottomhole assembly. After the maximum depth of 19,786 ft was reached, the SPECTRUM CT was set in position, and the integrity of the single mode-fiber (DAS – FiberVSP service) and multimode fiber (DTS – FiberLog™ service) contained within the CT was verified by means of an optical time-domain reflectometer (OTDR) measurement.

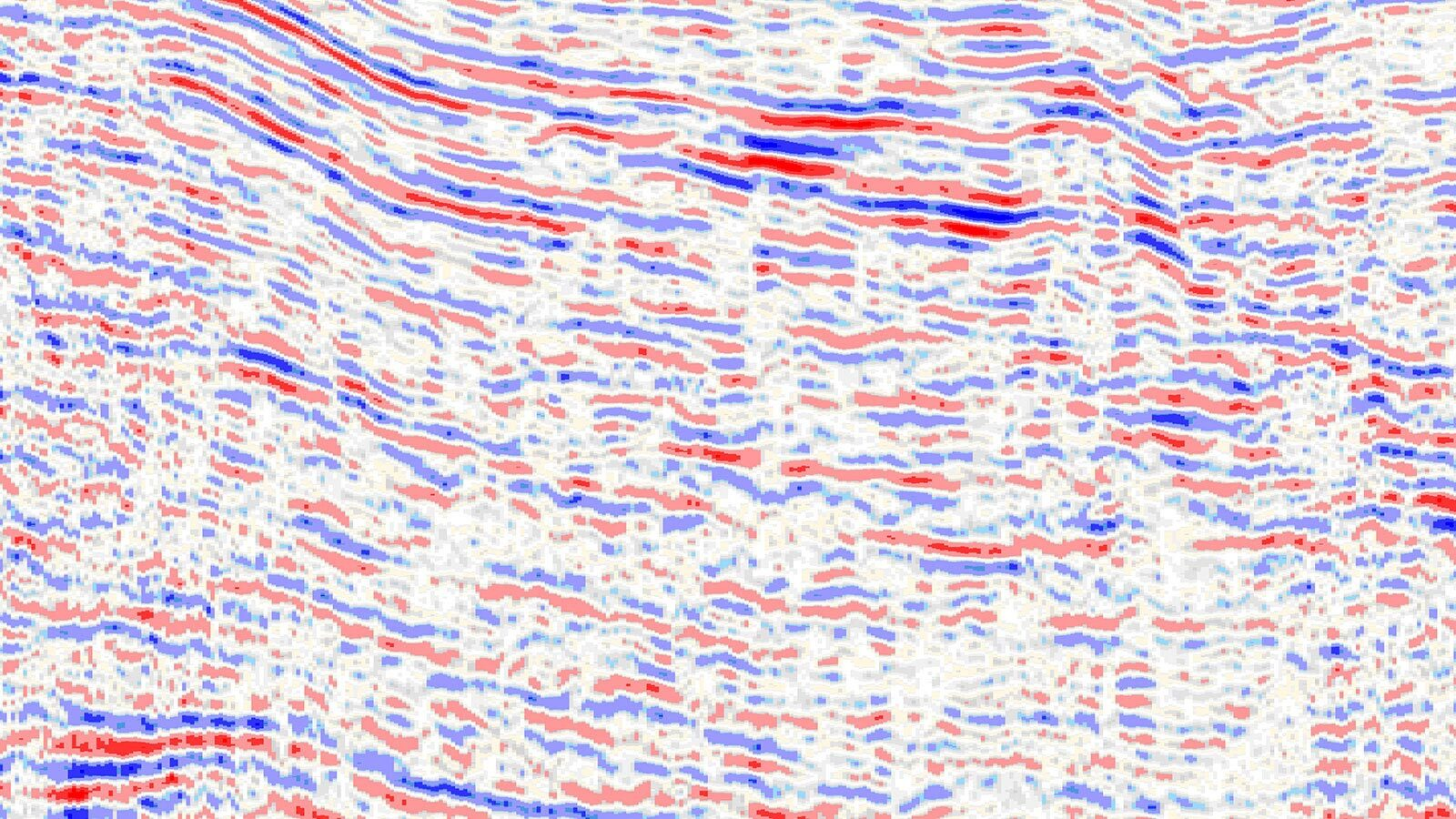

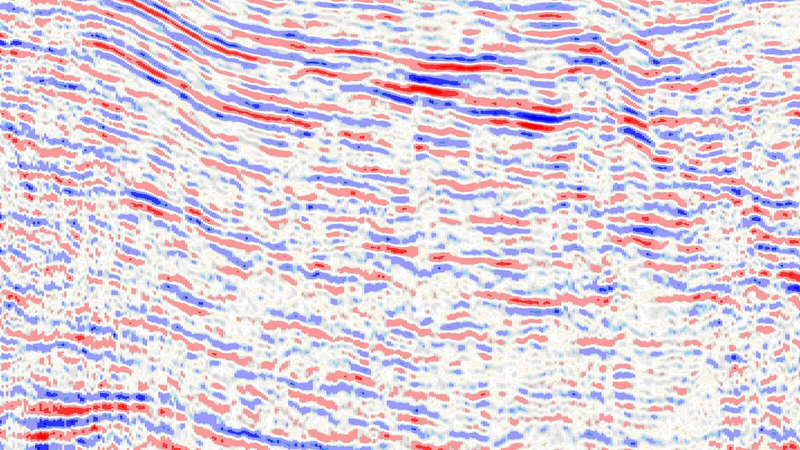

The CT FiberVSP data and previously collected surface seismic data exhibited an excellent match, which suggests that CT FiberVSP data is suitable to calibrate surface seismic data. The geophysical validity of the CT FiberVSP data was further evidenced by comparing the velocity profile derived from a conventional checkshot survey collected at a nearby well with the velocity profile extracted from the zero-offset CT FiberVSP data set. Again, excellent agreement between the two data sets is observed.

The use of a FiberVSP interrogator unit that enables real-time data delivery can significantly broaden the opportunity for VSP data acquisition during planned SPECTRUM CT interventions. Moreover, the capability to opportunistically acquire VSP data simultaneously while performing other SPECTRUM CT fiber-optic diagnostic services increases data acquisition efficiencies. Adding on the Halliburton FiberVSP service via coiled tubing is an easy and economical way for a reservoir engineer to maximize data collection during other planned acquisitions.

For more information about this case study, see technical paper: Vertical seismic profiling via coiled tubing-conveyed distributed acoustic sensing, presented at the SPE/ICoTA Well Intervention Conference and Exhibition.

The Halliburton FiberVSP™ service offers a quick, cost-effective, and low-risk solution for acquiring high-spatial-resolution VSP data.

SPECTRUM analytic tools give you insight deep into challenging wells.

Addressing the toughest issues in well intervention, Halliburton offers services to extend well life, improve performance, and limit downtimes.