Search

Search

Search

Search

Deep Water

Control fluid losses in depleted intervals to prevent wellbore collapse

Gulf of Mexico’s Lower Tertiary trend

A major operator required a solution for the complex completion requirements of wells in the Gulf of Mexico’s Lower Tertiary trend, an area that contains a productive pay with a gross interval ranging between 1,000 feet (305 meters) and 1,500 feet (457 meters) at a true vertical depth (TVD) of over 28,800 feet (8778 meters) with permeability between 5 and 50 mD. These wells require frac stimulation to enhance productivity and maximize reserve recovery.

In this area of the Gulf of Mexico, the use of single-trip multizone completion technology has traditionally been a cost-effective solution to the stacked pay. Typically, with these single-trip multizone completions, all of the zones to be completed are perforated at the same time, and the pressure gradients of these zones are similar enough such that the well can be controlled by the completion fluids. However, as these fields have matured, some operators have experienced formation pressure depletion in some of the pay intervals within the proposed completion, challenging this common completion method.

While maintaining well control of the higher-pressure intervals, the operator needed a solution for mitigating fluid losses to the depleted intervals in order to prevent excessive fluid losses. In the early planning of this project, several zones within the pay interval were identified as depleted and vulnerable to fluid loss. Therefore, a contingency plan was needed in the event that fluid losses were observed during the completion process.

As the drilling program progressed into the pay zone of the well, it became clear that this was going to be a challenging completion, and the operator began looking at alternative completion approaches.

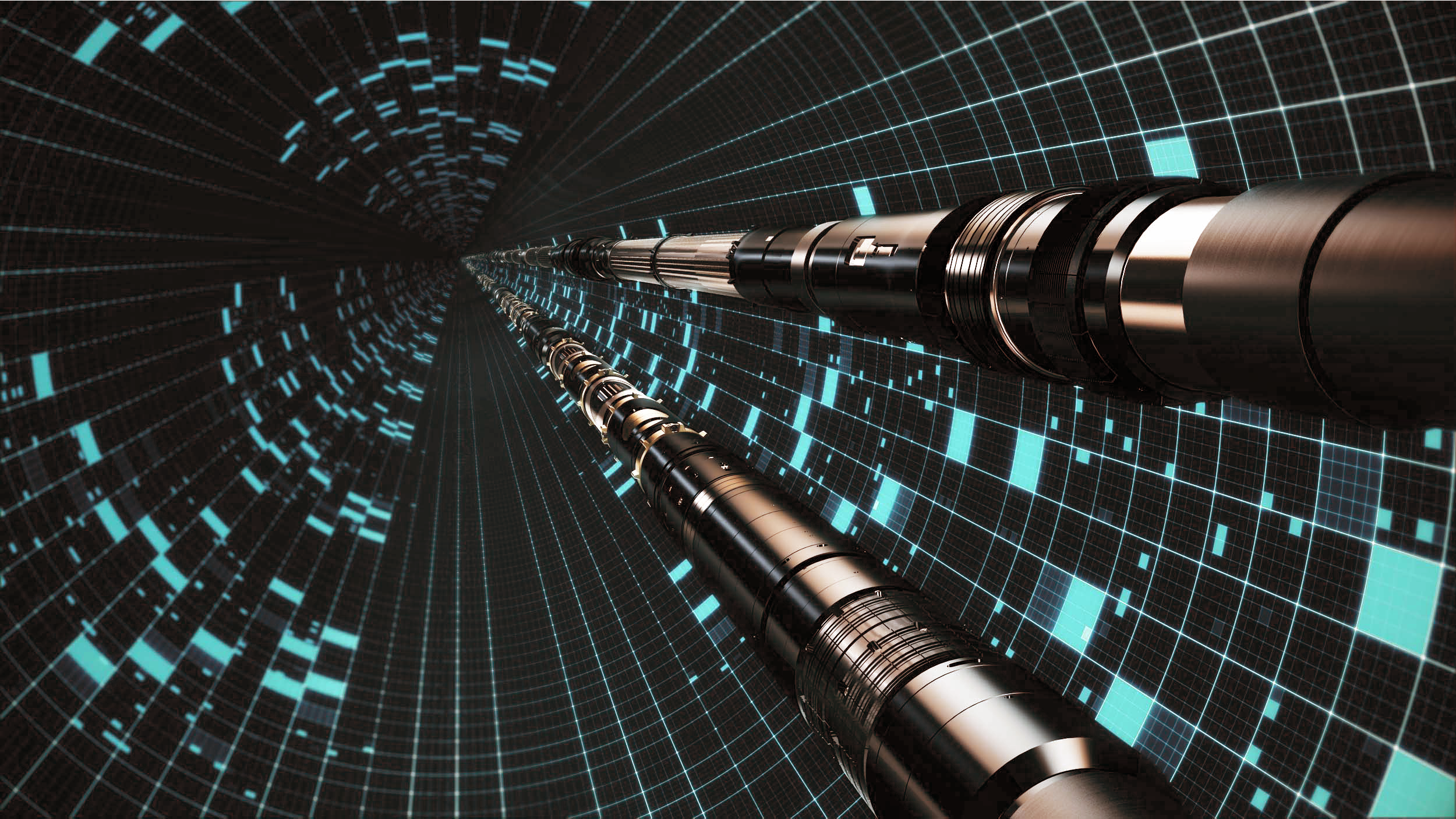

For this project, Halliburton recommended its Enhanced Single-Trip Multizone (ESTMZ) completion system, which was designed to meet the complex completion requirements of wells in the Lower Tertiary trend of the Gulf of Mexico. Designed for use in deepwater and ultra-deepwater completions, the ESTMZ system enables several intervals within a well to be isolated and treated with a high-rate frac pack during a single trip of the workstring.

To mitigate the high-pressure differential between zones, Halliburton and the operator collaborated to redesign the ESTMZ system so that it would complete a five-zone completion via a two-zone by three-zone stacked multizone completion.

This solution allowed separation of the lower two depleted zones from the higher-pressured upper three zones. In addition, the lower two zones would be perforated separately from the upper three zones in the event that the lower-pressure zones could not be controlled with the completion fluid weight of the higher-pressured zones. Perforating the lower two zones separately from the upper three zones allowed the fluid weight to be lowered to minimize fluid losses and still control the well.

After the lower two-zone ESTMZ system was installed and the zones were treated, the closed sleeves across those two zones isolated the zones from the wellbore and allowed the well to be changed over to a higher weight completion fluid in order to perforate the higher-pressured upper three zones. The upper three zones were then treated and the sleeves closed.

million estimated saved

wellbore collapse

ft true vertical depth

ft productive pay gross interval

For this well, the ESTMZ system was converted into a two-zone by three-zone stacked completion. The objective of this modified design was to allow the deployment of the sandface completion equipment without excessive fluid loss, and then place an effective stimulation treatment in each zone.

This strategy anticipated fluid losses and allowed the losses to be addressed and successfully contained. It was then possible to deploy the lower multizone system and stimulate all five zones in the well.

For each of the two-zone and three-zone system deployment and after stinging into the sump packer, the upper gravel-pack packer was set as per normal procedures. At this time, the perforations were isolated and the fluid loss dropped to zero bbl/hr. Once the service tool was released, the gravel-pack packer was tested, the string was moved back down to the run-in-hole position, and the isolation packer was set. This was all in accordance with standard multizone completion practices. From this point forward, the completion was very similar to the other completions performed by the operator.

Without this solution, the operator’s other alternative would have been to abandon or bypass the low-pressure intervals altogether, resulting in a loss of 40 percent of the productive pay in this well. Modifying the ESTMZ system to allow for stacked completion enabled the operator to effectively manage fluid loss, while still increasing completion efficiency by reducing the number of required workstring trips. The operator was also able to avoid a more costly conventional stacked five-zone completion, thus saving an estimated USD 20 million in additional costs.

Halliburton delivers reliable single-trip systems for any multizone application up to 15,000 psi.