Search

Search

Search

Search

Halliburton team executes P&A operation in complex and remote environment

Download PDFMature Fields

Design and implement a custom solution for a complex, under-river P&A project

Colombia

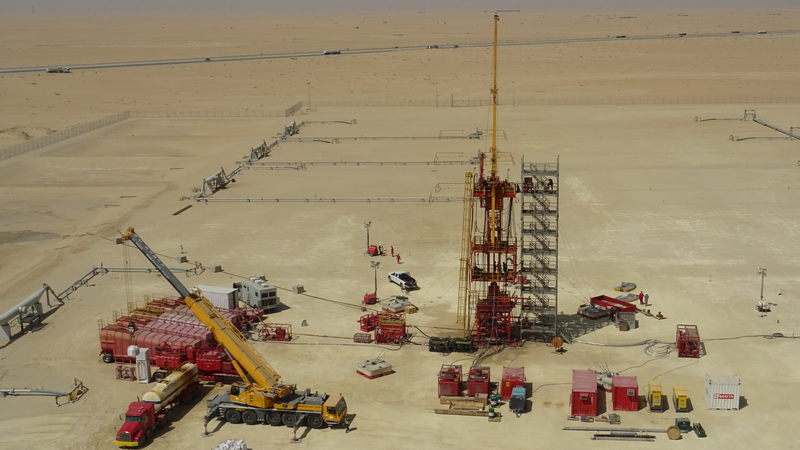

In Colombia, the Halliburton project management team was selected to provide integrated plug-and-abandonment (P&A) services for a well located midstream in the Magdalena river. The well was in a remote area in the middle of the Magdalena riverbed, with difficult access hindered by currents and flooding. Many studies of the riverbed were carried out, the results of which were used to model various scenarios of the riverbed conditions. These study results and modeled scenarios were applied as an input for designing the structures and providing safe, customized solutions.

This project was executed utilizing specialized technologies, such as well control services from Boots & Coots, a hydraulic workover (HWO) unit, and other well services involving wireline, cementing, fluids, and completion tools. Additionally, Halliburton provided engineering studies, river support barges, and well abandonment equipment. Halliburton teams also designed, built, and installed work support structures (providing piling and positioning) for the high fluctuations of water levels.

The under-river P&A project was performed in a very complex environment. River conditions and water depths allowed for only a limited operational window; therefore, an in-depth analysis of the location, river, and well condition were required to properly plan and safely execute the project.

Since the well had remained closed for 40 years and was located in the middle of the Magdalena river, well integrity was a challenge.

Other challenges that had to be addressed prior to the start of operations included:

To solve these challenges, the Halliburton team designed and implemented a customized solution reducing environmental and operational risks by maintaining well integrity and utilizing a robust risk management plan.

Given the challenges of this sensitive and complex environment, Halliburton assembled a multidisciplinary project team with experience in well integrity and hydraulic workovers to address the planning, preparation, and execution phases.

In addition to the complexity of the riverbed, another constraint that had to be considered during planning involved the seasonal river level, which allowed only a 10-week operational window when the barges could navigate through the river. Therefore, prior to execution, Halliburton collaborated with a local institution to carry out studies, such as soil surveys, along with the hydrology, topography, and bathymetry of the riverbed.

Once the engineering studies were completed and detailed well and location data were evaluated and analyzed, the team established the well program and multiple contingencies. The abandonment plans were aligned with key suppliers and the customer.

Based on modeling and studies of the complex river stream and riverbed environment, a working platform was designed, built, transported, and installed at the well’s location with a secured pile structure.

Next, Halliburton collaborated with the customer and subcontractors to generate an effective well integrity solution, along with a robust risk management plan for operations. To address significant deterioration of the wellhead, the Boots & Coots team performed a hot-tap job to evaluate and relieve annular pressures. This team also replaced deteriorated valves and other wellhead components.

The team also collaborated with the customer on procurement and social plans, focusing on the integration of the local community within the influence area. This was accomplished by hiring local personnel, subcontracting local providers, and safely performing the operations in compliance with the local requirements and regulations.

Operational success

HSE or service quality incidents

Ahead of schedule delivery

Compliance with customer requirements and regulations

Despite the many environmental and well integrity challenges, comprehensive advanced planning and preparation activities played key roles in the successful execution of this under-river P&A project. All phases (including well intervention, mobilization, and demobilization) were accomplished with no recorded HSE or service quality issues. This project was also delivered 6% ahead of schedule and in full compliance with customer contract requirements and local regulations.

Halliburton Boots & Coots engineers and executes well control risk and consequence mitigation.

Halliburton HWO units are the ideal well intervention solution for well maintenance, live well interventions, and re-entry operations.

Halliburton's wireline openhole logging tools are easily deployed to acquire critical subsurface data, ensuring reliable insights for operators in the industry.

Halliburton designs and delivers dependable barriers tailored to minimize risk and maximize production.

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.

Halliburton offers a comprehensive portfolio of completion tool solutions that are purposed engineered to help customers maximize asset value.