Search

Search

Search

Search

Inclusion of a Drill Tech® casing scraper in the running string improves setting and testing success

Download PDFUnconventional

Reduce trips in the well to save time and reduce costs

Norway

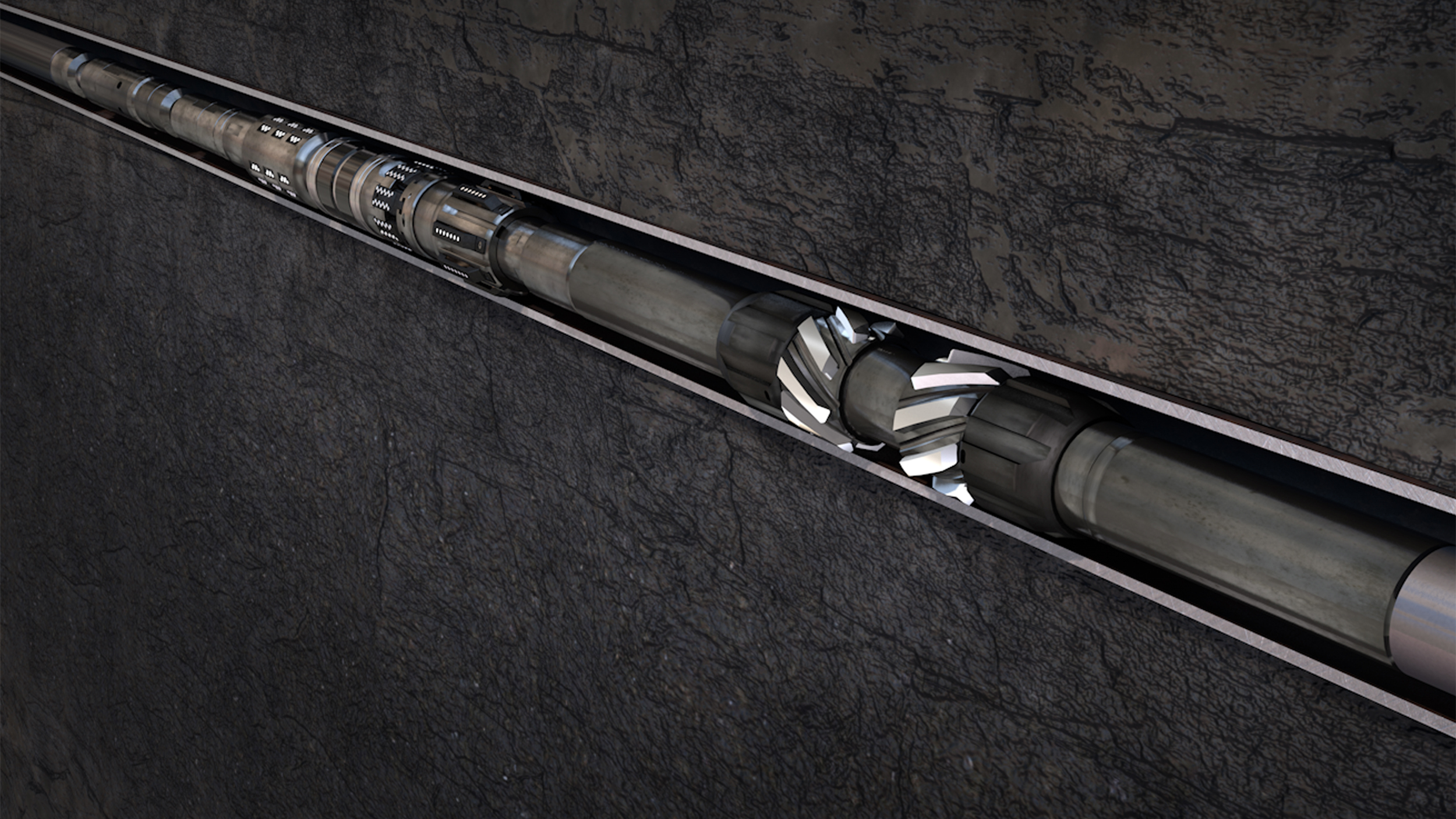

Downhole debris can negatively impact the success of permanent plug and packer operations. Thus, a run with cleanup tools is recommended to prepare the setting areas for installation. With increased pressure from operators to reduce rig time, this additional step is commonly skipped. As such, misruns attributed to debris have increased, which negatively impacts service quality records, even though additional trips in the hole are recommended. A “next best” practice is necessary to address this challenge and improve service quality without an increase to rig time or overall costs to the operator.

The operator required a solution that could benefit operations in terms of time and costs with no additional risk or impact to service quality. While there are drillable scraper/brush tools on the market designed to be run below the plugs/packers, they can significantly increase operational costs.

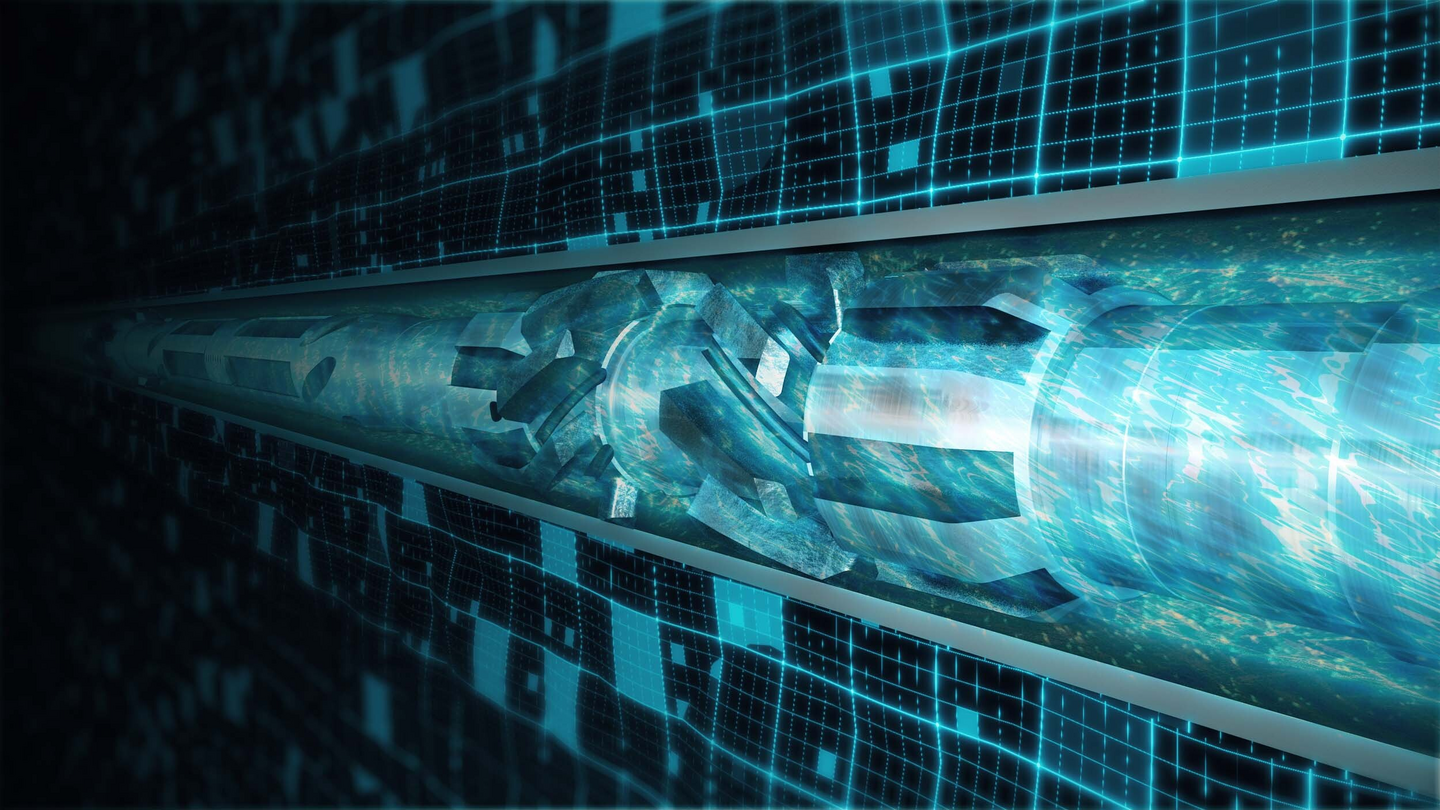

Halliburton proposed the inclusion of the Drill Tech® casing scraper in the running string of the permanent plug/packer. This cost-effective rental option creates no additional risk but provides the best opportunity to set and test tools on the first attempt. The Drill Tech casing scraper is a more robust solution to address residual cement/debris on the casing ID. This allows the operator to clean the casing for logging and future packer setting areas in the same trip. The cost benefits of a short-term casing scraper rental compared to the purchase of a drillable brush are tangible.

The Drill Tech casing scraper creates no additional drag on the plug/packer because it is centralized. No issues have been encountered to date spotting cement above the plug/packer; additionally, placement of a drillable type brush below the plug/packer is more likely to cause tension sleeve issues than a casing scraper in the string above.

issues spotting cement above the plug/packer

successful operations to date

reduction to operator costs

This solution provided both cost and time benefits to the operator and helped Halliburton improve its service quality record setting and pressure testing permanent plugs/packers. This method has been successfully deployed in more than 43 operations to date and provides tangible cost savings for operators.

Complete portfolio of filtration services, wellbore cleanup fluids, mechanical wellbore cleaning tools, and software modeling