Search

Search

Search

Search

Baroid solution helps save three days of rig time, while also significantly reducing fluid costs

Download PDFDeep Water

Increase the LOT results to minimize the operator's losses while drilling

Gulf of Mexico

A deepwater operator in the Gulf of Mexico frequently experienced severe lost circulation while drilling, running casing, and cementing. The pore pressure/fracture gradient (PP/FG) margin was very narrow. The operator wanted to increase the leak-off test (LOT) results to help minimize losses as the next interval was drilled.

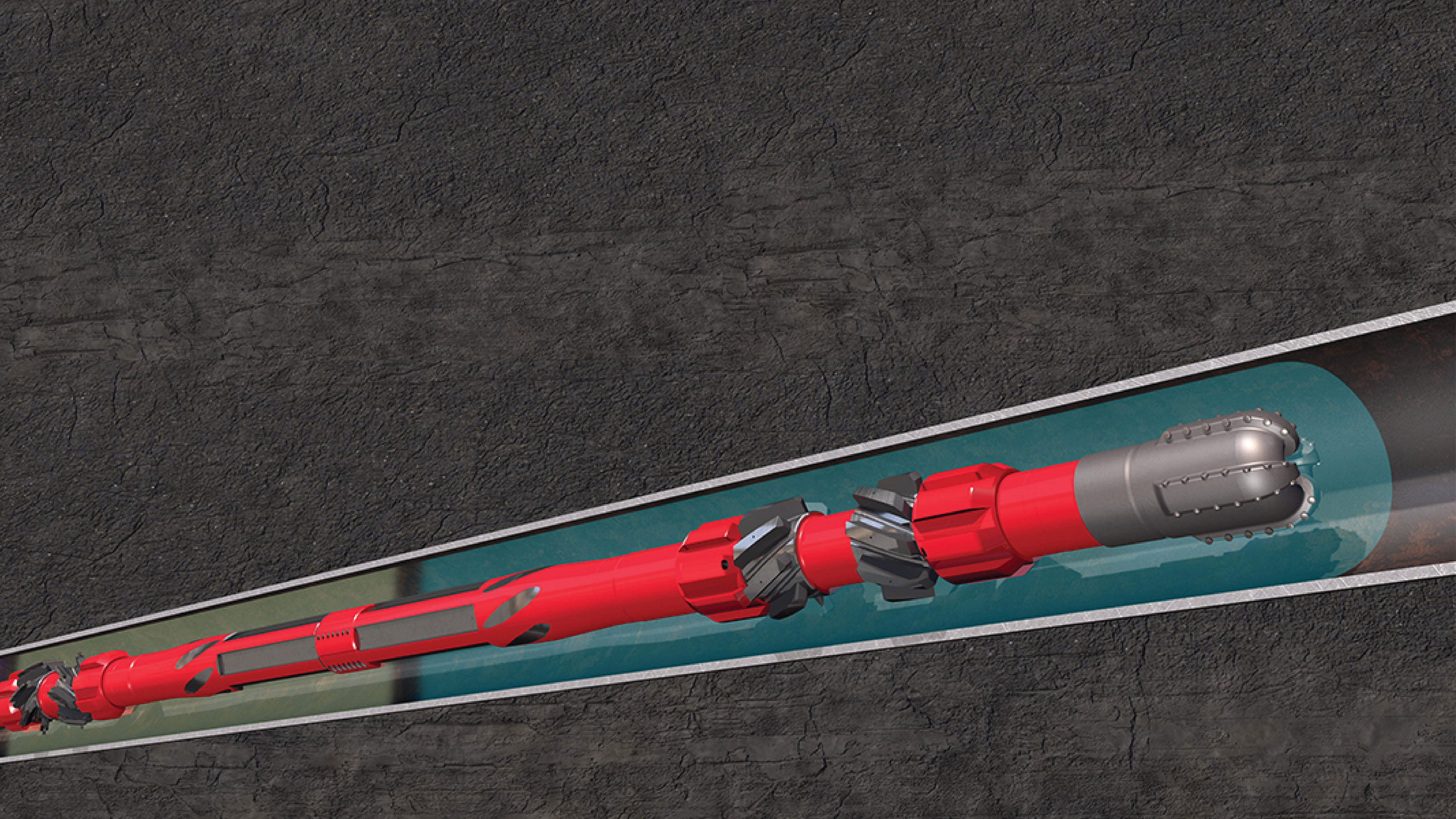

The 18 -inch x 21-inch hole section was drilled successfully with a 12.1-ppg BaraECD® high-performance non-aqueous fluid (NAF) – an organophilic clay-free system that can provide improved drilling performance and help minimize the risk of lost circulation in narrow PP/FG conditions. A 16-inch casing string was set and cemented with zero losses, enabling the drilling of 10 feet (3 meters) of new formation below the casing seat.

The operator wanted to mitigate potential losses in the next interval by applying a wellbore strengthening (WBS) treatment prior to performing the LOT in the 10-foot (3-meter) rathole. The initial goal was to increase LOT results by 0.4–0.5 ppg at the 16-inch casing shoe.

Determining the optimal lost circulation material (LCM) blends for the WBS package would require extensive analysis and testing, based on the formations to be encountered and the correct particle size distribution (PSD) needed to bridge and strengthen the rock matrix.

For drilling, Baroid personnel recommended continuing with the optimized BaraECD NAF, while treating the active system with specific LCM blends that had been customized based on the depletion of wells in this area. The BDF™-974 LCM, a blend of finely ground materials, was added and maintained at 18 ppb throughout the entire well. The separate WBS package consisted of a 20-ppb blend of coarse materials, including equal parts of BARACARB® 600 and BARACARB 1200 ground marble, STEELSEAL® 1000 resilient graphitic carbon, and BAROFIBRE® seepage loss additive.

ppg increase on the LOT

feet measured depth (MD)

days of deepwater rig time saved

After treating and conditioning the active fluid system (BaraECD NAF) with BDF-974 LCM in conjunction with the WBM LCM package, the operator was able to achieve an increase of 1.6 ppg on the LOT, which was beyond the initial incremental target of 0.4–0.5 ppg.

The 14½-inch x 16½-inch interval was drilled with mud densities ranging from 12.1 ppg to 13.5 ppg. Only minimal seepage losses occurred. At interval total depth (TD), the 14-inch casing was run and cemented with full returns.

The operator then drilled the 12¼-inch hole section to a measured depth of 30,131 feet (9184 meters) with 13.8-ppg to 14.0-ppg NAF, and set the 9-inch x 10¾-inch tieback string with no losses.

This successful procedure saved three days of deepwater rig time, and helped reduce fluid costs by preventing significant downhole losses.

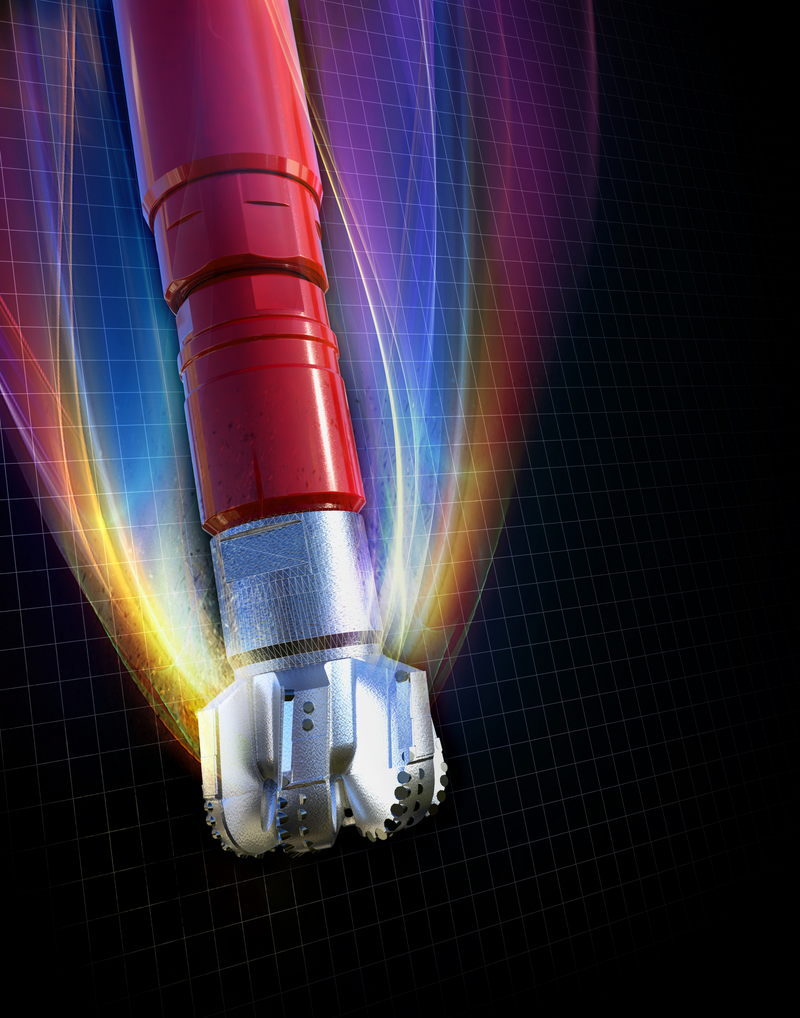

Mitigate pressure challenges and simplify completions with our most advanced NAF

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.