Search

Search

Search

Search

Tight timelines and water conservation goals complicated the project, which required equipment, specialty chemicals and technical expertise on site

Download PDFMiddle East

Remove pyrophoric iron sulfide from eight separate units

Remove pyrophoric iron sulfide from eight separate units during a refinery turnaround.

Two Halliburton service lines collaborated to fulfill the scope of work.

Halliburton met all customer requirements for the project, while providing all equipment, chemical products, manpower and technical expertise.

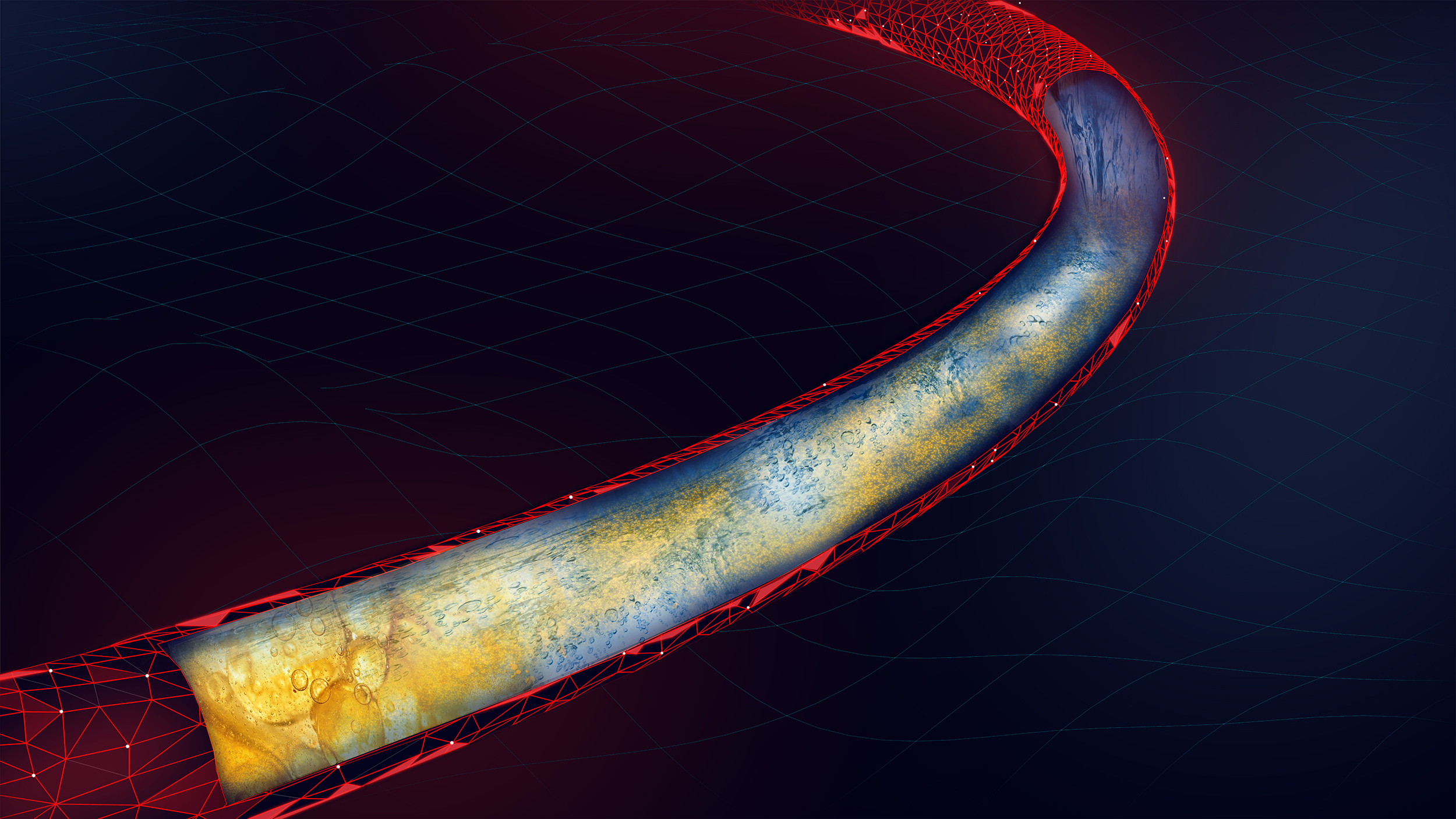

A major new refinery in the Middle East was looking for a company to decontaminate eight separate units during its first major turnaround. The process involves a two-phase application of specialty chemicals to remove pyrophoric materials that reduce throughput and pose a serious fire risk.

With Halliburton’s Pipeline and Process Services PSL providing local manpower and equipment and the Athlon/Multi-Chem PSL providing the chemicals and onsite technical expertise, we were able to offer a cost-effective solution that didn’t involve using subcontractors for any part of the Scope of Work. The result was a streamlined project that met operational objectives in a cost-effective manner.

Because the project involves a varied scope of work — project management, manpower, equipment, specialty chemicals, and onsite technical consulting — it is standard for bidding companies to use one or more subcontractors for these types of jobs. However, this can complicate an already complex and critical task – removing the buildup of combustible iron sulfide from refinery equipment.

This particular chemical cleaning and decontamination job included cleaning a 90-meter-high crude distillation column with a total volume capacity of 6,000 M3, plus two desalters units with significant H2S and sludge waste content.

Halliburton leveraged its expertise in specialty chemicals, downstream operations and project management to complete this complex job under a tight time frame. RPA-880, an H2S scavenger from our downstream specialty chemical product line, was applied to each refinery unit to form sulphates. A wetting agent, MX 5-4225, from our upstream production chemicals product line was then applied to solubilize the sulfates in water and remove it from the system. The wetting agent also included limonene, which helps degasify and addresses other contaminants while also providing a pleasant citric smell.

Following Halliburton’s treatment regimen, the H2S found in each unit had been completely eliminated. Additionally, LEL percent, which indicates the risk of combustion was reduced to zero. All customer requirements were met and the project was completed on schedule and without any safety or environmental incidents.

Halliburton provides unparalleled technical expertise and customized specialty oilfield chemicals from the reservoir to the refinery

Diagnostics, chemicals and engineered solutions to support the full life cycle of pipelines and processing facilities.