Search

Search

Search

Search

Service identifies low-rate gas leak in production casing

Download PDFMature fields

Identify and repair gas leak to get well's production back on track

Alaska

Caelus Energy Alaska had a well with a gas lift completion experiencing inner annulus (IA) to outer annulus (OA) pressure communication (95 psi/day OA buildup) when the IA was pressurized with gas. Because of the leak, the well could not be gas lifted, limiting production. Previous attempts to locate leaks in the field with ultrasonic leak detection technologies were unsuccessful, and efforts to solve this problem were abandoned. Halliburton proposed locating the leak using the leak and flow diagnostic tool. The gas-only leak was activated by pressurizing the IA while bleeding pressure from the OA. The entire well was logged with the tool, and additional stationary readings were taken at zones of interest. High-definition waveforms and flow map processing identified a shallow leak in the production casing hanger, while ruling out several zones of interest by using radial location, which is unique to the tool. Since the leak was identified near surface, Caelus Energy Alaska plans to use a sealant repair method and avoid a USD 3 million workover operation. Another leak in a gas lift mandrel was remedied with a dummy valve, which was confirmed to be successfully repaired during a subsequent run.

Caelus Energy Alaska had a well with a gas lift completion experiencing inner annulus (IA) to outer annulus (OA) pressure communication (95 psi/day OA buildup) when the IA was pressurized with gas. The well could not be gas lifted due to this leak, limiting production. Previous ultrasonic leak detection technologies were unable to reliably locate such leaks, which affected several of this operator’s wells, and efforts to solve this problem were abandoned.

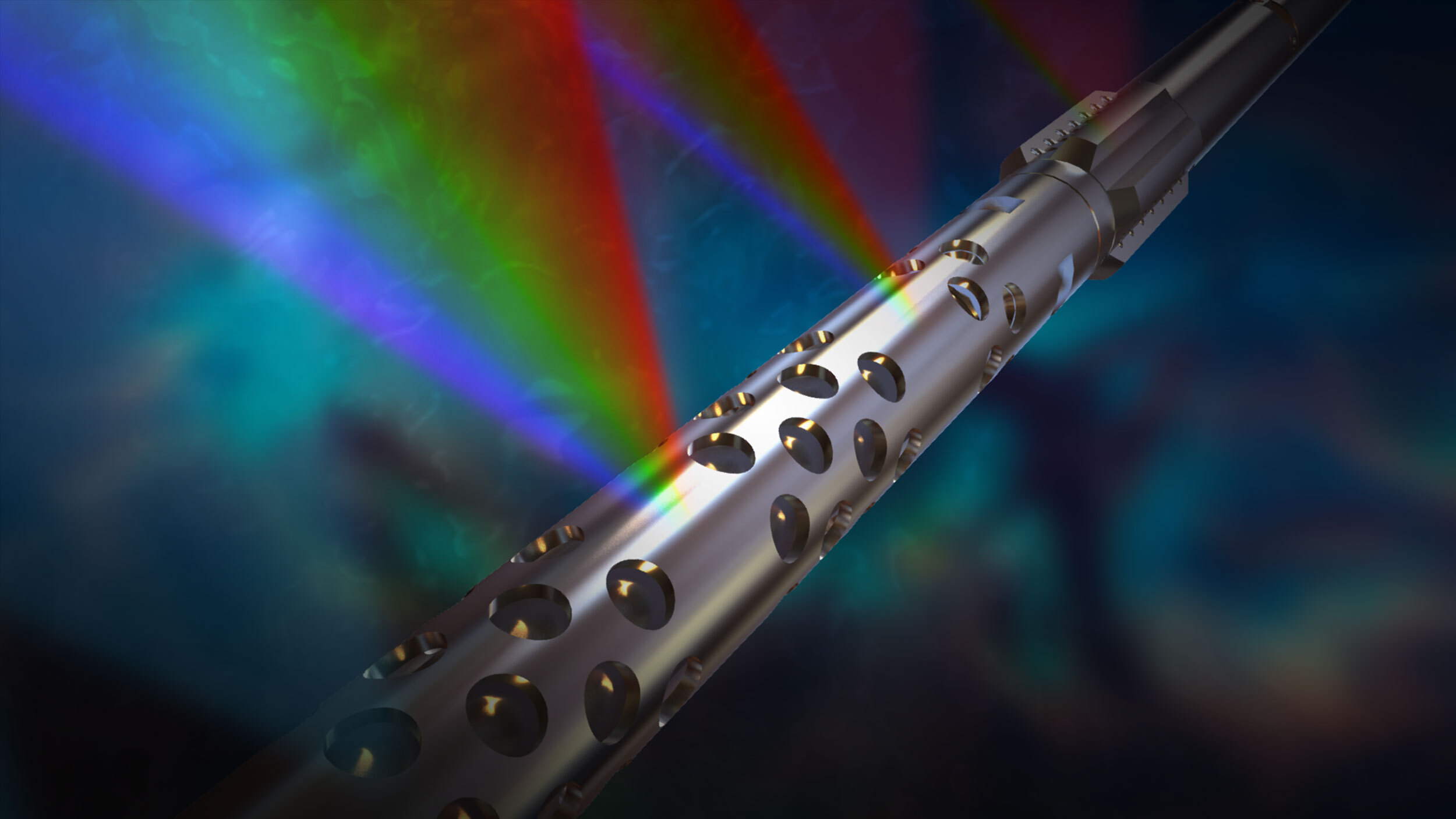

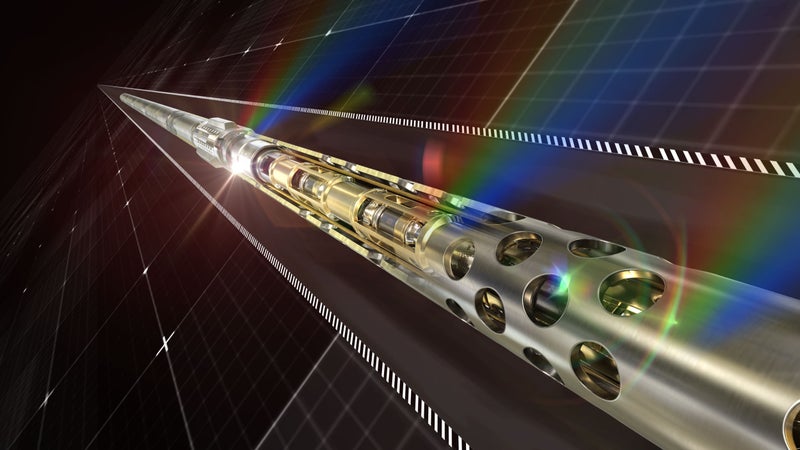

Halliburton proposed locating the leak using the leak and flow diagnostic service, which uses hydrophone array technology to locate and describe communication paths and flow areas – vertically and radially – in the wellbore area in real time. The array triangulates on the sound/flow source in or around the wellbore. Array analysis also helps eliminate false readings that have more to do with the well structure than the leak source.

The radial locator has proven invaluable in some wells that have been logged by identifying which annulus or component of a completions system is leaking.

The gas-only leak was activated by pressurizing the IA while bleeding pressure from the OA. The entire well was logged with the tool, and additional stationary readings were taken at zones of interest. One such zone was near the production casing hanger, which is where the leak was identified by using high-definition waveforms and flow map processing. This same processing was able to rule out several other zones of interest by using radial location, which other ultrasonic technologies cannot do. An additional leak (IA to tubing) was located at a gas lift mandrel and was confirmed to be repaired on a subsequent tool run after the Halliburton Slickline group changed out the dummy valve.

Workover operation avoided

Acoustic analysis tools that pinpoint costly wellbore leaks by analyzing sound waves that describe flow patterns in the formation and casing.