Search

Search

Search

Search

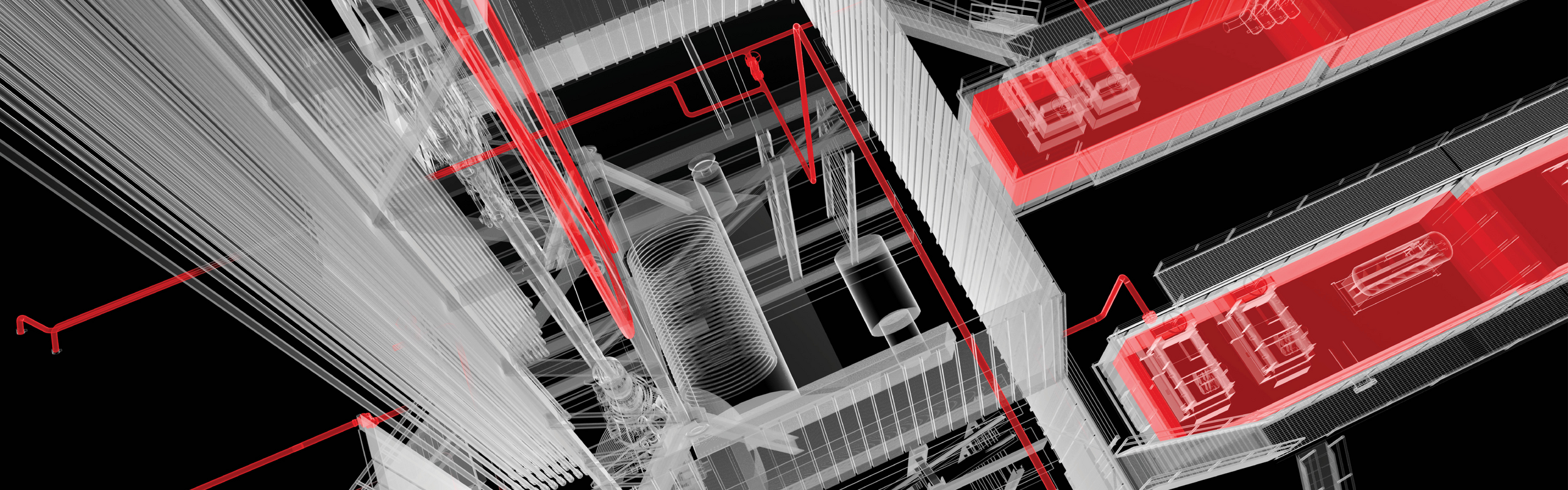

Mature Fields

Use drilling fluids to eliminate frequent backreaming and sidetracking

West Qurna Field, Southern Iraq

An operator in Iraq’s West Qurna field faced hole cleaning challenges in the 8-1/2-inch and 6-1/8-inch intervals, as the wellbore transitioned through the build section (40–60° angle) into the 1,250-meter (4,101-foot) horizontal step-out. This was the first horizontal well drilled by the operator in this area.

Drilling on offset wells had been delayed by frequent backreaming and sidetracking in the 8-1/2-inch section. There was a high risk of stuck pipe and loss of the well.

The maximum allowable mud density was closely restricted, so that pumping weighted sweeps was not an option. After applying the Baroid Technical Process to analyze potential challenges and solutions, the Baroid team recommended pumping pills built with BAROLIFT® sweeping agent to achieve effective hole cleaning. BAROLIFT sweeping agent, a synthetic fiber, increases the carrying capacity of fluids without significantly altering rheological properties. This would improve suspension while minimizing impact on equivalent circulating density (ECD).

Each 2-m3 pill was formulated with 0.15 ppb of BAROLIFT material. The sweep program was tailored to meet changing wellbore conditions, as shown below:

This program was applied throughout the tangent and lateral hole sections. The mud exhibited good carrying capacity, and there were no backreaming delays during trips. The wellbore remained in good condition at all times, in contrast to the significant issues that had been experienced on offset wells. In addition to executing the sweep program, Baroid personnel monitored drilling parameters using Drilling Fluids Graphics (DFG™) hydraulics modeling software. Fluid properties and drilling parameters were optimized in real time to maintain effective cuttings removal efficiency. DFG modeling outputs were discussed with the operator, then used to adjust sweep frequency and to manage ECD.

Feet Total Depth (TD)

USD Saved

Days of Rig-Time Savings

Using BAROLIFT sweeping agent and DFG modeling software, the operator was able to reach total depth (TD) 10 days ahead of plan, saving approximately USD 800,000. The logging operation was completed successfully, allowing the retrieval of essential information about this reservoir. The intermediate and production intervals (7-inch and 4-1/2-inch strings, respectively) were cased and cemented with no delays or problems.

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.