Search

Search

Search

Search

Operator achieves greater than 80 percent injectivity with effective drill-in fluid and filter cake breaker systems

Download PDFDeep water

Drill injection well for deepwater enhanced oil recovery (EOR)

Mississippi Canyon, Gulf of Mexico

A major operator in the Gulf of Mexico planned to drill an injection well for a deepwater enhanced oil recovery (EOR) project in 3,942 ft (1,201 m) of water depth. The 6.5-in. horizontal injection zone was highly depleted, and there was a high risk of severe lost circulation while drilling the 2,200-ft (670 m) lateral. Effective removal of the drilling fluid filter cake was also a top priority, as this would help ensure reliable injectivity at the specified rates.

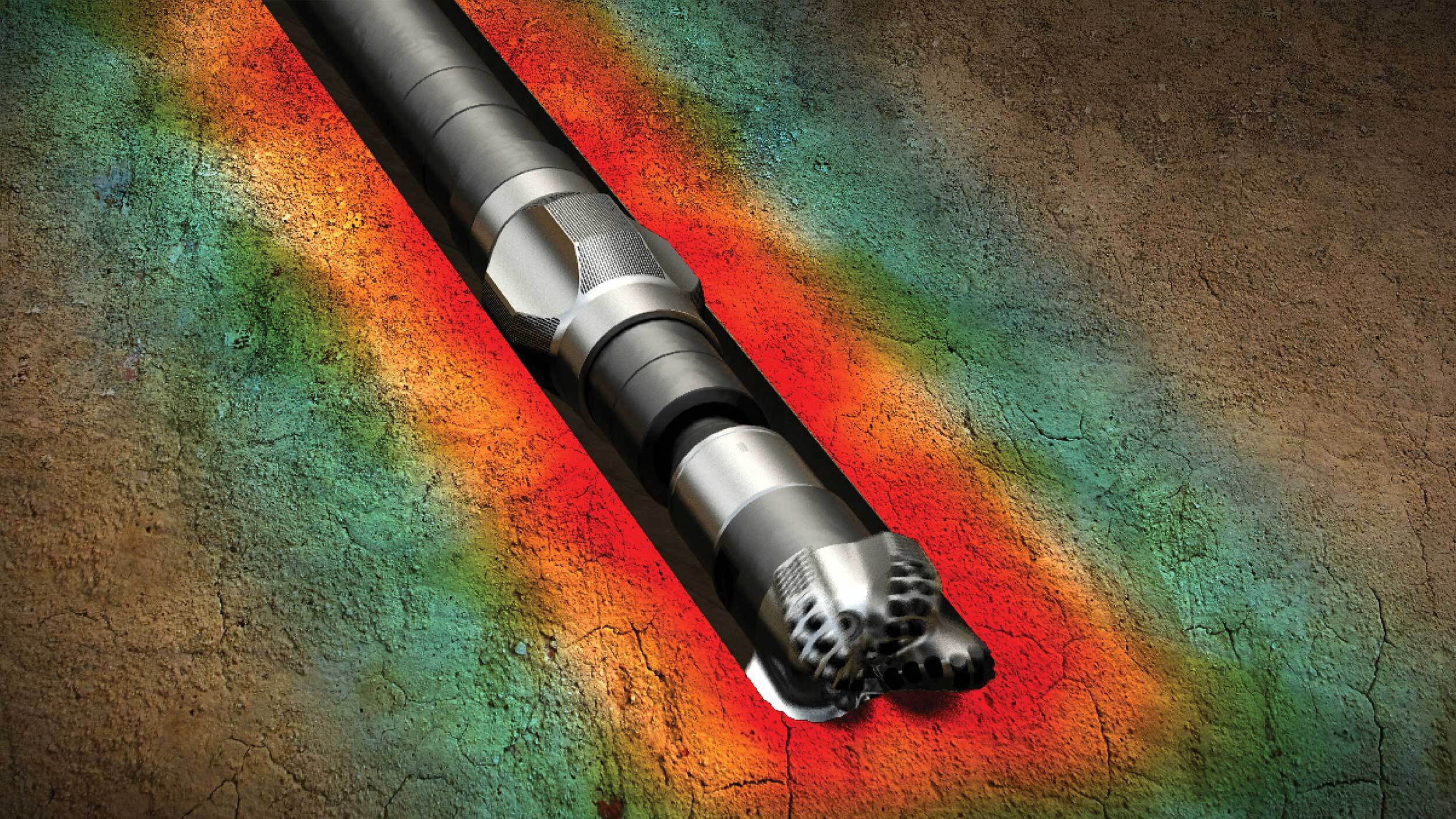

The Halliburton Baroid team was asked to design a reservoir drill-in fluid (RDF) that would exhibit the proper rheological properties to minimize losses in the narrow pore pressure/fracture gradient (PP/FG) environment. Further, the RDF should contain only acid-soluble solids as weighting and bridging agents. This would facilitate filter cake removal and protect the injection zone from solids plugging.

The fluid design project included testing the proposed RDF with filter cake breakers to determine which combination would deliver the best results.

The proposed BaraXcel® RDF was optimized with a focus on the delivery of an acid-soluble fluid with the ability to minimize losses while drilling the depleted zone. Sized BARACARB® ground marble would provide proper bridging and sealing to protect against formation damage, and then would be easily removed during the acid treatment. BaraKlean®-648 cleaner, a powerful blend of surfactants and solvents, was recommended as a component of the filter cake breaker. BaraKlean-648 cleaner is soluble in all common brines and is effective in the removal of a range of water-, oil- and synthetic-based fluids. As a breaker component, it breaks down the RDF emulsion, and enables the acid treatment to dissolve the water-wet solids.

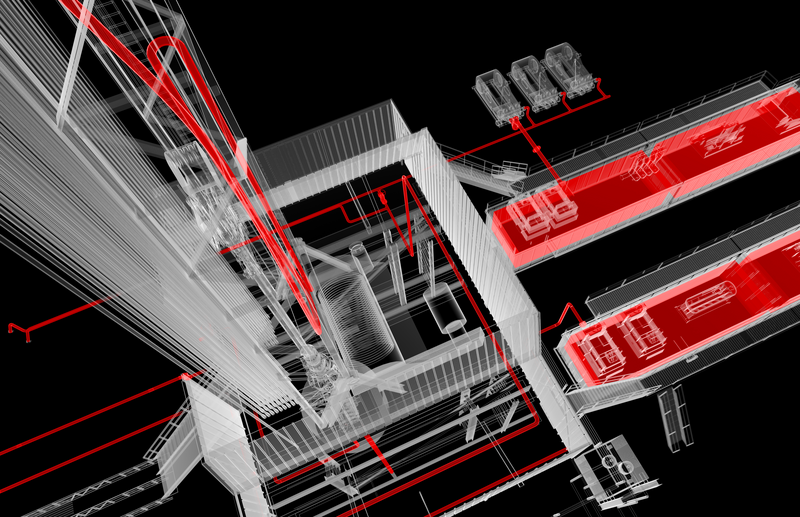

To optimize the breaker system performance, the BaraKlean-648 additive must be injected into the acid blend on the fly, prior to entry to the work string. Taking advantage of rigsite synergies, Baroid personnel planned to use the Halliburton production enhancement liquid additive skid to inject the cleaner into the breaker acid treatment. Injection rates could be monitored with multiple flow meters and adjusted in real time based on the total flow rate. This would ensure that the correct concentrations were maintained in the breaker fluid.

First, 100 bbl of the breaker was spotted in place from heel to toe. Then, after shifting the gravel-pack tool, an additional 122 bbl of breaker was spotted from toe to heel.

foot injection interval

fph average penetration rate

percent injectivity achieved

The 2,218-ft (676 m) injection interval was drilled at an average penetration rate of 45 fph with no downhole losses beyond seepage. There was no requirement for additional background BARACARB bridging agent in the active system. The wellbore remained in good, workable condition with no tight hole issues. Screens were successfully run to bottom (18,748 ft/5,714 m true vertical depth, and 22,763 ft/6,938 m measured depth).

The BaraKlean-648 cleaner helped remove the BaraXcel RDF filter cake, as validated by flow-through testing with the RDF and breaker samples. Laboratory results indicated greater than 80 percent injectivity and met the operator’s objectives.

This successful application of BaraXcel RDF and BaraKlean-648 additive is now considered a best practice for upcoming injector wells in the field.

Discover how this clay-free, non-aqueous fluid system can help you upgrade drilling performance.

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.