Search

Search

Search

Search

High-performance system provides substantial savings

Download PDFUnconventionals

Design and use a diesel-based fluid while drilling a narrow-window shale lateral

La Calera Field, Argentina

An operator in Argentina’s La Calera field planned to drill the 6-1/8-inch lateral section in a shale reservoir after setting 7-inch casing at 2,600 meters (8,530 feet) true vertical depth (TVD). The proposed total horizontal displacement was 1,512 meters (4,961 feet) measured depth (MD), reaching total depth (TD) at 4,662 meters (15,295 feet).

Offset well data indicated the necessity for high-density drilling fluid to maintain well control, often exceeding 2.0 SG (16.7 lb/gal). The high densities caused increases in rheological properties, resulting in higher equivalent circulating density (ECD) values and standpipe pressures (SPPs) when drilling the lateral section. Downhole losses had been encountered.

The plan for the subject well included both coring and wireline logging operations. The operation needed to control potentially high pore pressures, recover 100 percent of the core sample, and prevent hole enlargement or irregularities that would impair wireline data acquisition. After logging runs were completed, production casing would be set and cemented in the lateral. Achieving and maintaining optimal wellbore conditions were essential elements for success.

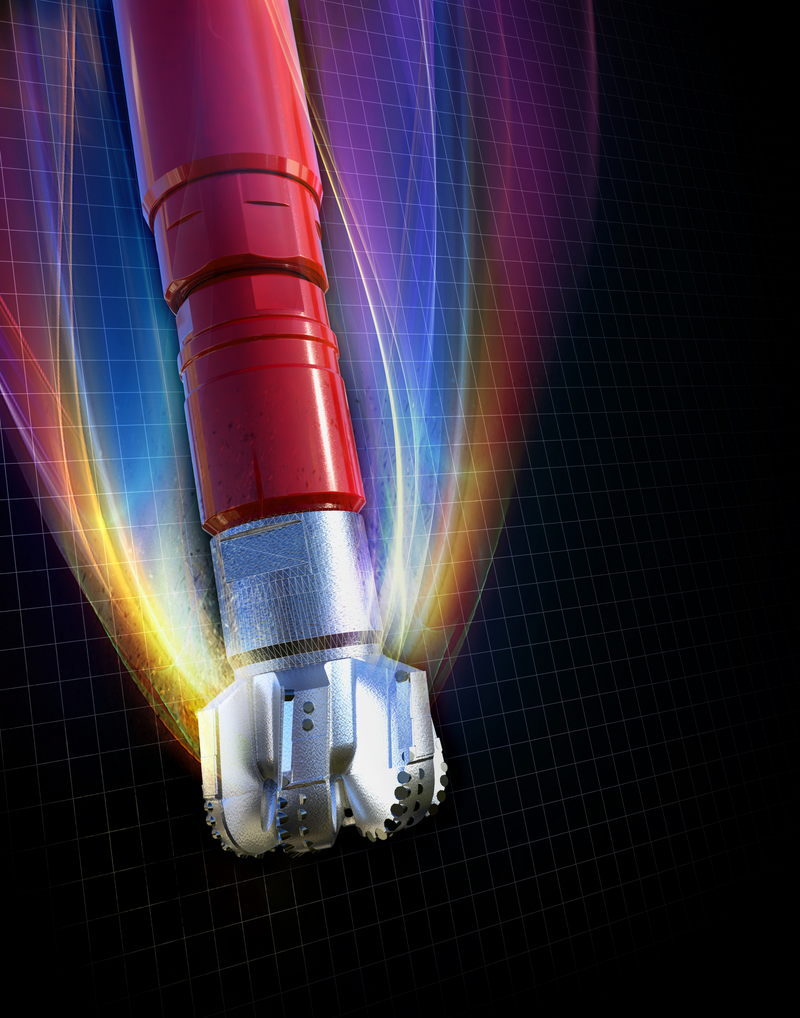

The Baroid technical team proposed running a BaraECD® high-performance non-aqueous fluid (HPNAF) formulated with diesel as the base oil. The BaraECD system has been proven to provide a low controlled ECD in wells with a narrow margin between the pore pressure and fracture gradient, while also providing necessary hole cleaning and resistance to barite sag to drill the intermediate, pilot hole, and lateral sections.

The fluid was designed at the Halliburton lab in Neuquén, with technical support from Bolivia-based personnel. The diesel-based HPNAF exhibits an exceptional low-end rheology achieved by including a customized suspension package built to exacting specifications. The result is a highly stable fluid that can remain static for long periods without risk of settling. On this well, the BaraECD system was used successfully in conjunction with managed pressure drilling (MPD) to increase the operator’s flexibility and control over pressure management.

As this was the first time the BaraECD fluid had been used in Argentina by this operator, the well was deemed a “critical first well” candidate. A global technical field advisor (GTFA) was assigned, and the GTFA and local team were also supported by regional and global experts.

The mud density was managed between 1.96–2.06 SG (16.4–17.2 lb/gal), and the fluid exhibited a flat, stable rheology profile compared with conventional oil-based mud (OBM) used on offset wells.

USD saved

reduction in fluid losses

feet total depth (TD)

Throughout the drilling operation, the BaraECD system delivered ECD values in a manageable range, reducing overall downhole losses and helping to prevent the onset of wellbore instability in the Vaca Muerta formation. Circulating pressures stayed well below the limits of the rig equipment.

Coring operations were performed from 2,912 meters (9,554 feet) to 3,011 meters (9,879 feet) (recovering 100 percent of the core samples). Eight wireline runs were conducted successfully while drilling the 1,512-meter (4,961-foot) horizontal section to TD at 4,662 meters (15,295 feet). Wiper trips were performed smoothly, and production casing was set and cemented with no issues.

Drilling with the BaraECD system delivered several significant benefits for the operator:

Mitigate pressure challenges and simplify completions with our most advanced NAF

Navigate challenging pressure windows between pore and fracture pressure in complex wells to reduce drilling days and NPT.

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.