Search

Search

Search

Search

Continuous application improves oil and water quality, eliminates tank cleanouts for operator in the Permian

Download PDF

North America

The approach essentially eliminated the problem with iron sulfide solids. Since the treatment began:

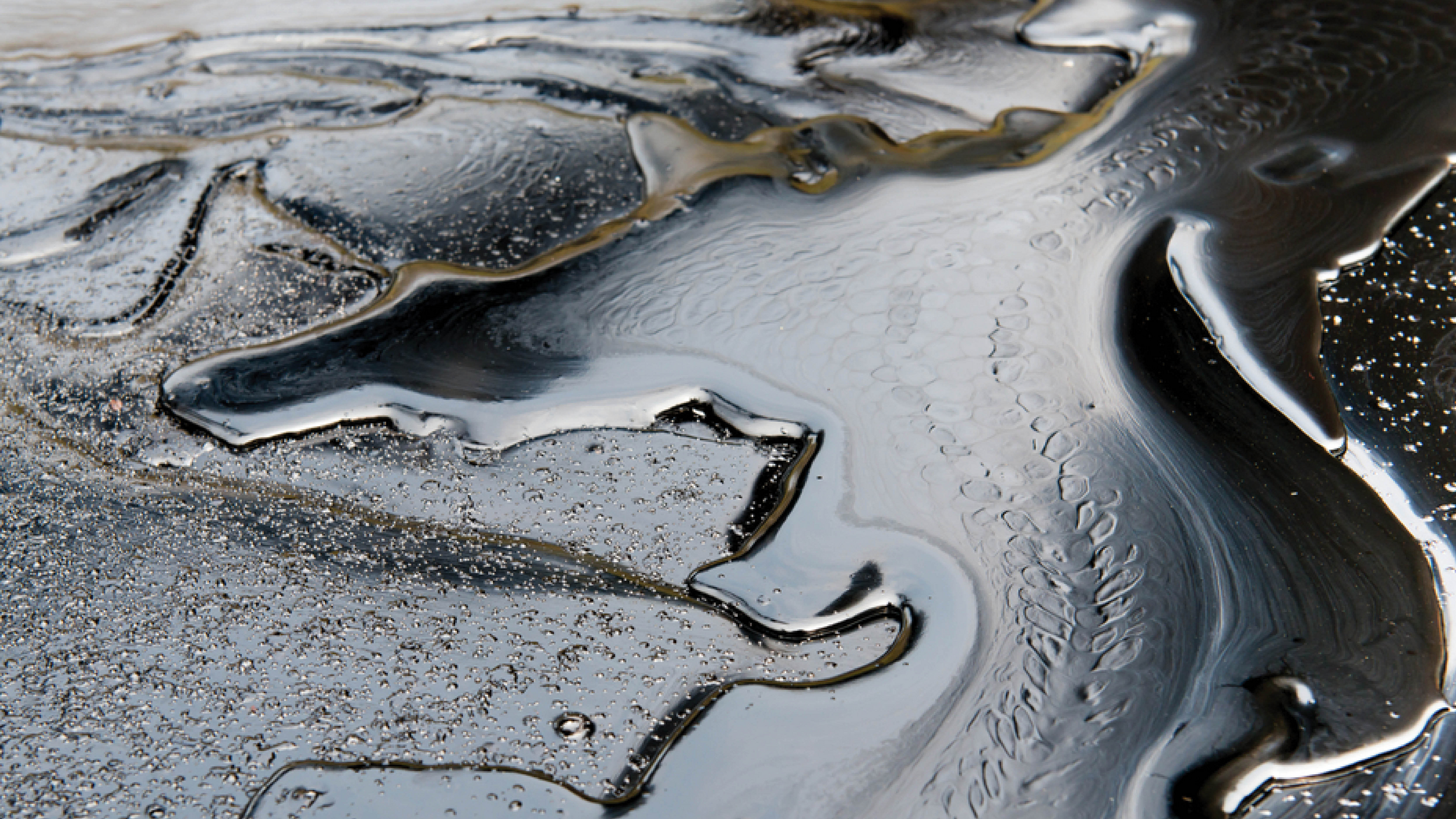

Iron sulfide (FeS) developing from the commingling of incompatible produced fluids in a West Texas operator’s tank battery caused a host of problems with the process stream: large interface pads in the gun barrel and water tanks, water in the oil tanks, oil carryover and black sludge in the system, and high H2S levels throughout. Multi-Chem, a Halliburton Service, was engaged to resolve the issue and recommended a continuous application of AcroClear®, an acrolein treatment designed to eliminate toxic H2S gases and FeS solids. The approach effectively removed the FeS and alleviated the need for other time-consuming and expensive operational workarounds.

Produced fluids from two high-producing wells with high H2S rates were combining with production from 16 other wells from different formations with elevated iron. This commingling led to the problems with FeS solids in the tank battery.

The interface pads and contamination of the water and oil streams that resulted forced the operator to shut in wells every month to allow for manual clean outs of the tanks. Sales oil regularly failed to meet pipeline specifications with BS&W levels in excess of 4%, which required reprocessing of the oil. Traditional batch treatments with a competitor’s acidic chelator were having a limited effect and caused new challenges by upsetting the system’s pH balance and raising corrosion risks. The operator resorted to re-piping the tank battery to delay the comingling of the two production streams to avoid the formation of FeS solids. This configuration bypassed an oil separation process that contributed to elevated hydrocarbons being transported to the saltwater disposal well.

Multi-Chem technical professionals visited the site to assess operations, sample produced fluids and conduct water analysis to determine the best treatment approach. They recommended treating the system continuously with AcroClear, an acrolein-based H2S scavenger and iron sulfide dissolver that consistently outperforms conventional chemical solutions.

The team established two injection points. The first was at the commingled stream from the 16 high-iron wells. The other treated the water stream for the two high H2S wells. The combined initial dose rate was 21 gallons/day. It was optimized down to 18.5 gallons/day. The water- and oil-soluble sulfide controller is able to penetrate the oily coatings on iron sulfide particles, clarify black water and rid discharge of iron sulfide solids. AcroClear is a simple organic molecule that is non-corrosive and does not affect the pH of an aqueous system.

The reaction between H2S, iron sulfide and acrolein produces a low molecular weight, highly water soluble by-product that is stable and prevents the regeneration of H2S and FeS. The rapid reaction with dissolved H2S can be an advantage when retention time is an issue.

At the start of the field trial, dissolved H2S levels at the outlet pump were 6 ppm and the levels of total suspended solids (TSS) were 300 mg/L. By the end of the trial, H2S levels were less than 1.0 ppm and the TSS was maintained at or below the 100 mg/L threshold.

The approach worked quickly with an almost 50% reduction in TSS within the first 10 days.

The reduction in solids throughout the tank battery and improved water quality delivered major benefits to the operator, including:

These improvements mean higher production volumes and money saved by eliminating less-effective treatments.

Following the success of the field trial, the operator made the treatment program at the site permanent and requested a continuous AcroClear treatment approach at another facility.

Halliburton provides unparalleled technical expertise and customized specialty oilfield chemicals from the reservoir to the refinery