Search

Search

Search

Search

Successful implementation of acrolein batch program reduces downtime, improves corrosion rates, and improves crude quality

Eliminate solids buildup and corrosion with Halliburton’s chemical solution

Permian Basin

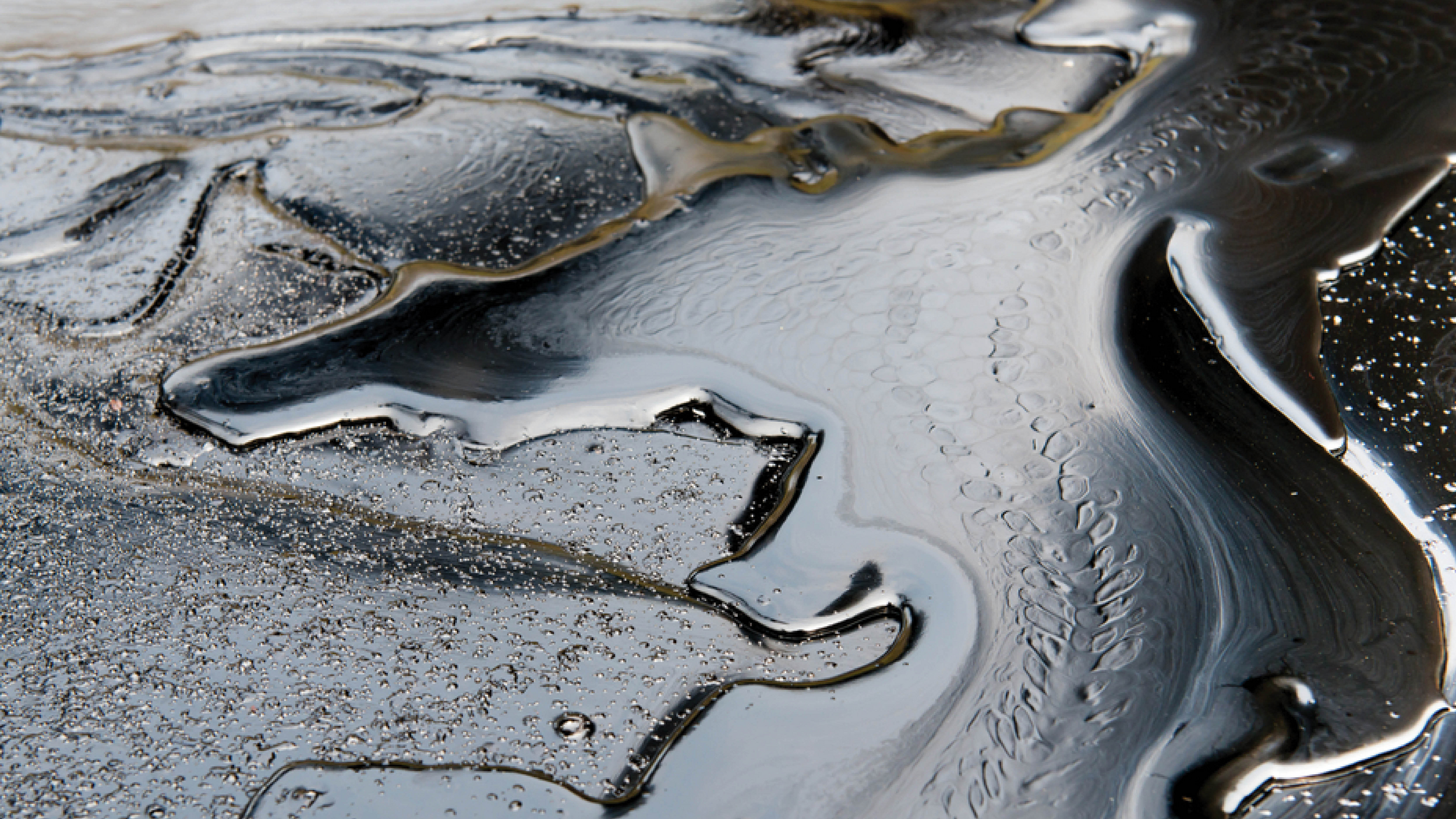

A Permian Basin pipeline operator was experiencing nearly 8 mpy corrosion on a 78-mile, 8-inch, wet-oil pipeline. Large amounts of iron sulfide and calcium carbonate solids were mechanically removed through pigging on a regular basis – sometimes monthly. Despite regular pigging and a combination corrosion/scale chemical inhibition program, solids buildup and corrosion continued to create operational risks for this operator, who is looking for cost-effective solutions to ship sour crude without service interruptions.

AcroClear is a water- and oil-soluble sulfide controller, allowing it to penetrate oily coatings on iron sulfide particles, clarify black water, and rid discharge of surface-sheening iron sulfide solids. Unlike acid or THPS (tetrakis (hydroxymethyl) phosphonium sulfate) treatments, AcroClear is a non-corrosive solution that does not affect the system pH, nor is it affected by iron concentrations. The highly reactive dissolver works quickly, completely and irreversibly. The extremely rapid reaction between our AcroClear product and H2S can be an advantage when retention time is an issue.

Multi-Chem recommended a five-day batch application of AcroClear at a dosage of 45 ppm to eliminate the solids, which were serving to exacerbate corrosion by providing a cathodic surface and interfering with the corrosion inhibitor’s ability to create a passivating film on the metal surface of the pipe. The batch of AcroClear was supported with a small dosage (9 ppm) of MC SS-5685 (acetic acid) to dissolve calcium carbonate scale.

Reduction in corrosion rate

H₂S generation

completely and irreversibly dissolved

Halliburton provides unparalleled technical expertise and customized specialty oilfield chemicals from the reservoir to the refinery