Search

Search

Search

Search

732-day run pulled with all pumps passing API inspection saves $900,000 in operating expenses

Download PDFUnconventionals

Solids falling out of the solution can become lodged in pump stages

West Texas

Unconventional wellbores in West Texas frequently experience power-related shutdowns. When the electric submersible pump (ESP) equipment is not running, produced frac/formation sand can fall back out of the solution and re-enter the ESP, lodging in pump stages.

Restart attempts after a shutdown can overstress motors, accelerate pump wear, overheat the cable, and/or result in catastrophic failure. In unconventional sandy wellbores, the volume of solids in solution exacerbates the issues. This issue can shorten ESP run life to as little as 180 days in West Texas wells.

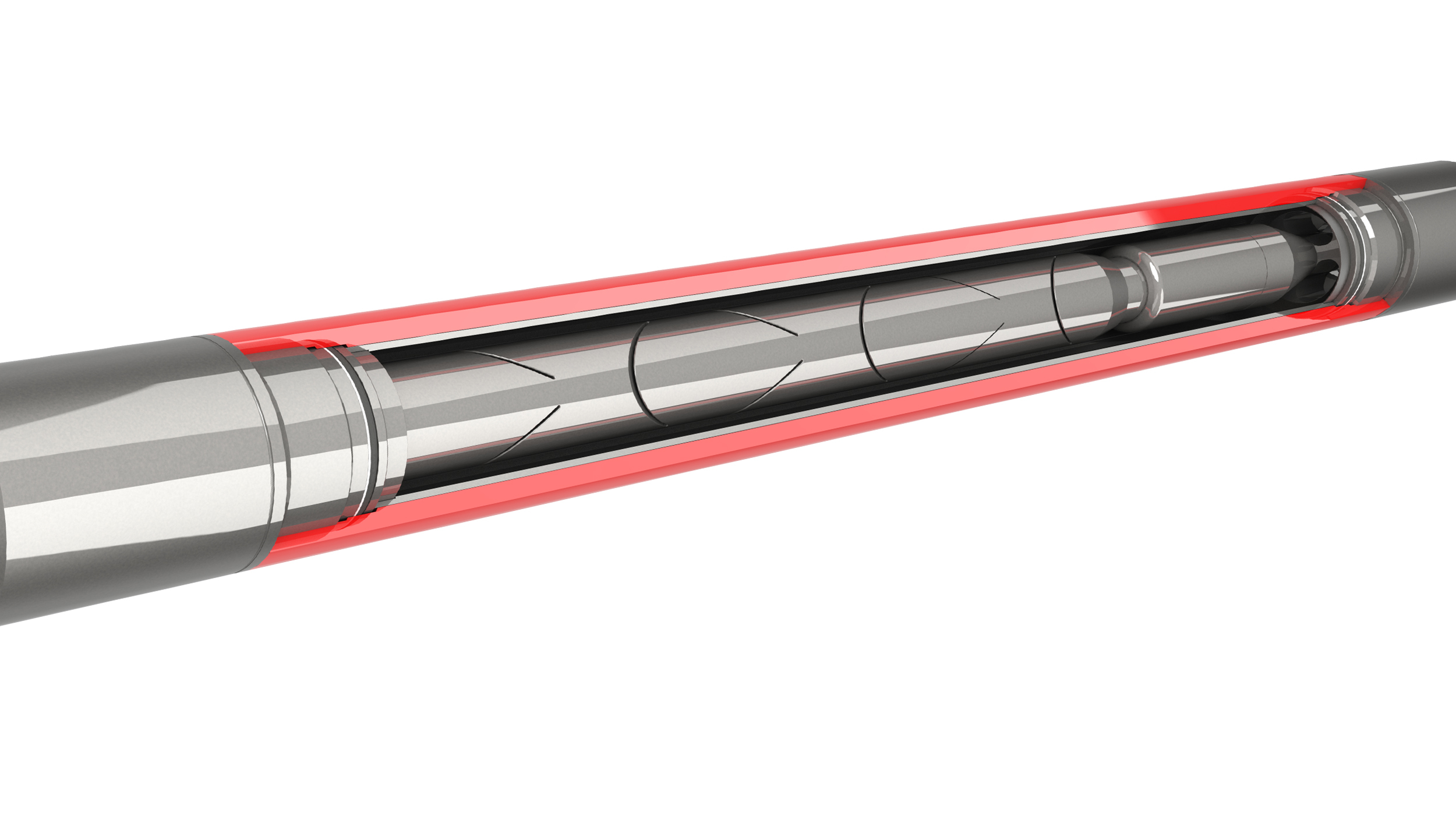

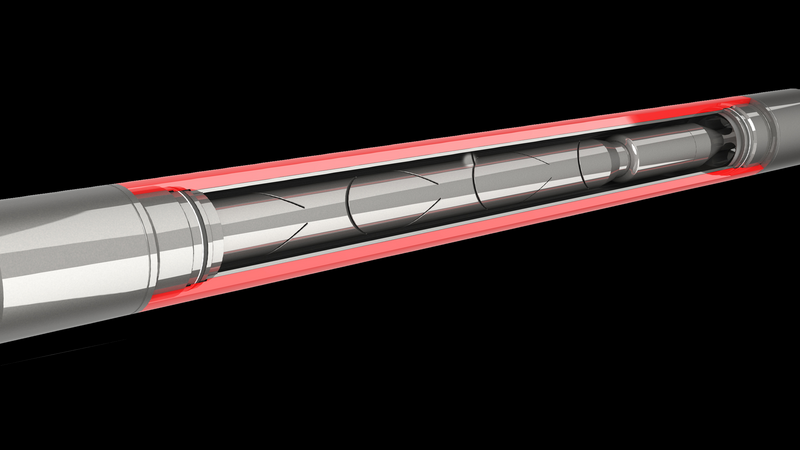

Developed with Halliburton’s frac engineers, the SandRight solids fallback preventer deters damaging solids from re-entering the ESP during shutdown events. This allows ESPs to resume stable operations without suffering from hard restarts. Compact and easy to deploy, SandRight’s capabilities address common issues associated with most fallback preventers, including erosion/corrosion, paraffin buildup, incompatibility with desanders, and jamming issues. Additionally, it retains the ability to perform through-tubing chemical treatments.

The operator, an early adopter of the SandRight fallback preventer technology, has installed over 150 units with zero sand fallback-related failures. A highly corrosive well with 55,000 PPM H2S was recently pulled when production fell off after 732 days. The Sandright performed its job with distinction: all pumps passed API testing despite shutdowns occurring an average of every 12 days over the two-year run life. The extended run time quadrupled the normal ESP run time in this area, saving the customer roughly $900,000 in operating expenses.

Sandright installations

Failures

Days run

Saved

The SandRight® tool prevents solids from entering the ESP system during shutdown events, eliminating overstressed motors and accelerated pump wear when restarting the system.