Search

Search

Search

Search

Flexibility and reliability for challenging and complex wells

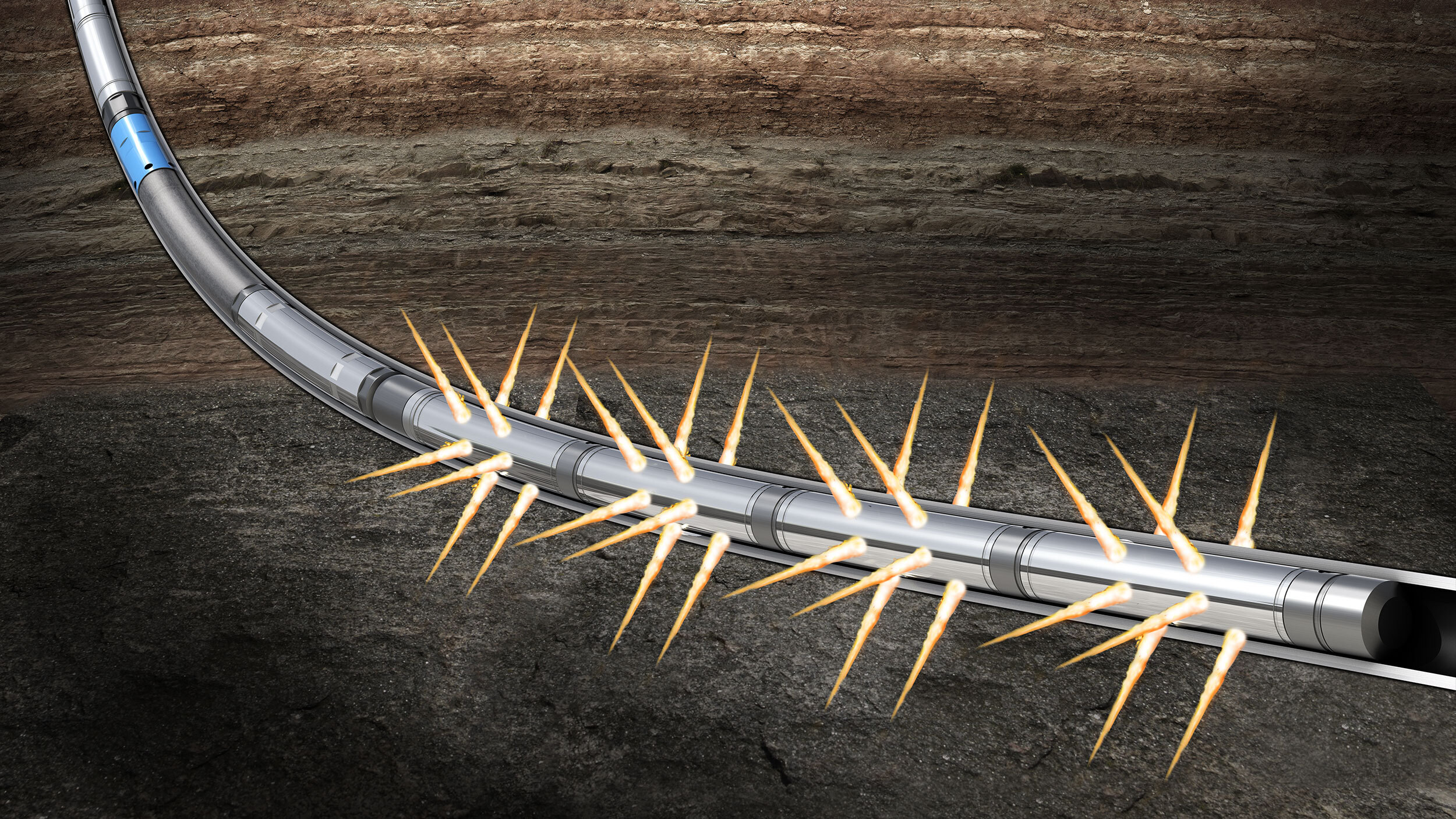

Talk to an expertThe Halliburton MaxFire electronic firing system (EFS) has numerous built-in features that enable explosive tools to be deployed and initiated safely. Halliburton makes three versions of the MaxFire system – one for tubing-conveyed perforating, one for slickline and coiled tubing, and one for RELAY™ digital slickline (DSL). Regardless of conveyance, the MaxFire systems have become synonymous with safety, precision, and flexibility.

No other firing system on the market offers the flexibility of the MaxFire electronic firing system – which can be safely deployed in any situation that calls for perforating casing, cutting pipe, or setting plugs – without the necessity for hiring multiple service providers to be on site.

The RF-Safe Rig Environment Detonator (RED®) tool, used in conjunction with the MaxFire system, provides triggering options suited to virtually any well. And because the RED tool is free from RF interference, rig site communications can safely continue during perforating operations.

No other firing system in the world offers the data recording capabilities and pressure ratings of the MaxFire electronic firing system.

The flexibility of the MaxFire EFS family makes it ideal for a variety of challenging applications and environments.

The fully programmable MaxFire provides unmatched capability, allowing low pressure-cycle operation, immediate or delayed detonation, or can initiate multiple gun assemblies independently on command.

MaxFire is ideal for cutting pipe during intervention. The conveyance flexibility of MaxFire allows fast and efficient use of explosive jet cutters conveyed on coiled tubing, slickline, or Relay DSL, which can result in significant cost savings. MaxFire tools can initiate any type and size of cutter for severing pipe.

Setting Plugs and Packers

The use of explosive setting tools is no longer limited by wireline conveyance. Using MaxFire, plugs and packers may now be set using conventional explosive setting tools conveyed on tubing, coiled tubing, slickline, or Relay DSL. MaxFire’s programming flexibility can provide delay times from many minutes to hours or days and can be tailored to work under virtually any completion sequence.

CASE STUDY / MaxFire Electronic Firing System

During a challenging operation on a deepwater well, lightning struck the derrick, disabling the top drive, drawworks, roughneck, and compensator, shutting down operations for almost 24 hours. MaxFire EFS enabled the operator to avoid a trip out and back in to check the affected bottomhole assembly for any necessary repairs or changes – thus saving the operator approximately USD 2.2 million.

Read the Case Study