Search

Search

Search

Search

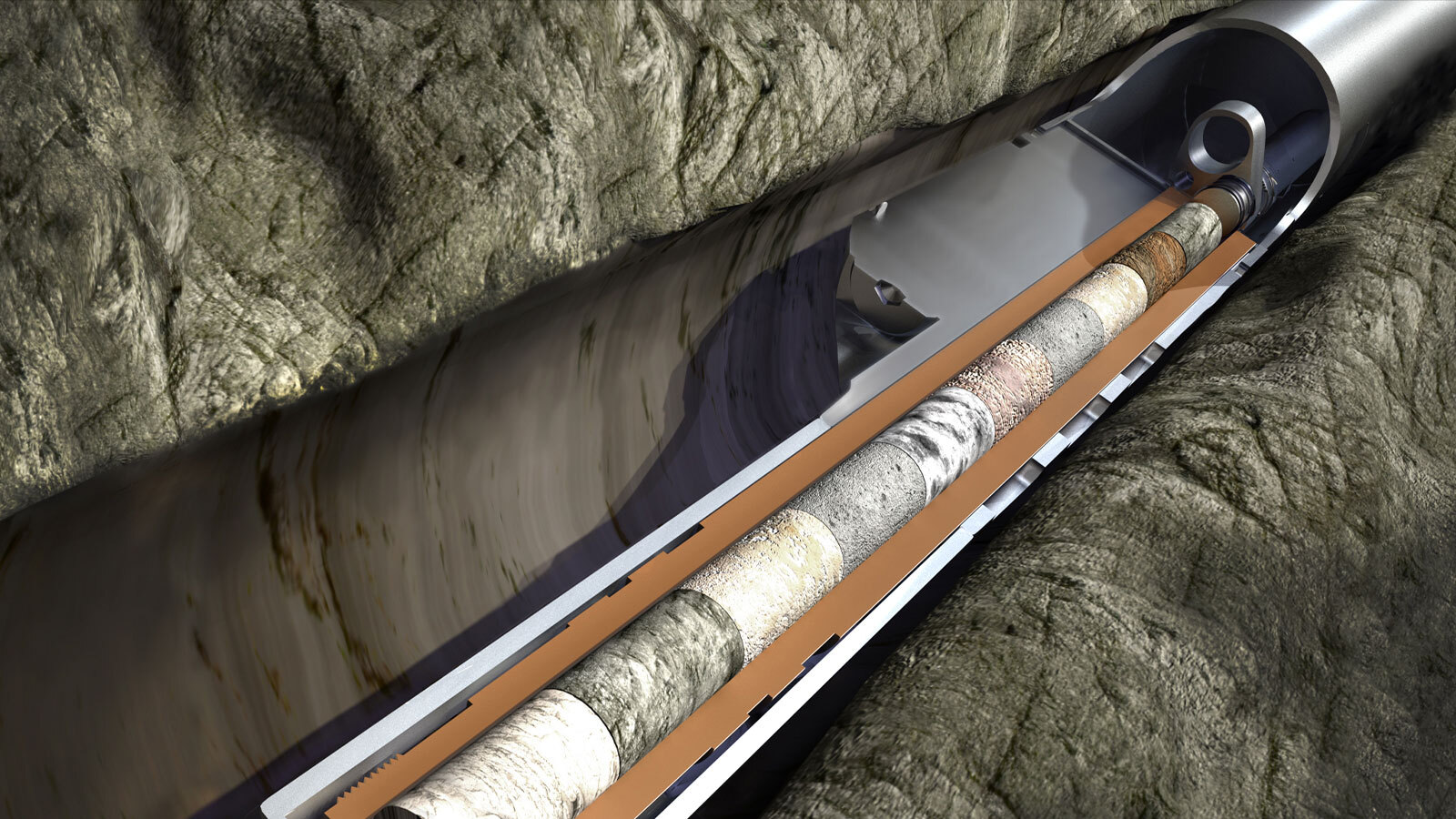

Our CoreVault solution captures up to 10 core samples in a sealed pressure vessel–in one run. Our vessel safely locks critical reservoir fluids in your cores

Talk to an expertBy preserving 100% of the fluids within the core sample, we're able to define critical fluid properties of the hydrocarbons in the reservoir. This enables a more accurate simulation of production—a world's first for the industry.

Traditional coring tools let fluids escape from samples as they depressurized. As a result, analysis had to be based on estimates of fluids lost rather than measurement of fluids in place. Measurements of samples obtained with the CoreVault system showed 2.5 times more oil and gas in place than previously estimated.

With a fully automated coring system controlling all parameters, the ability to core in the toughest environments is possible. Our system can operate in either pressure- or torque-controlled coring modes that optimize the coring time.

Traditional rotary coring services can't identify if a core is actually recovered. Operators must waste valuable rig time taking extra cores or must make additional runs to acquire missed cores. Our tool accurately measures each core cut, guaranteeing your core has been recovered from every requested depth.