Search

Search

Search

Search

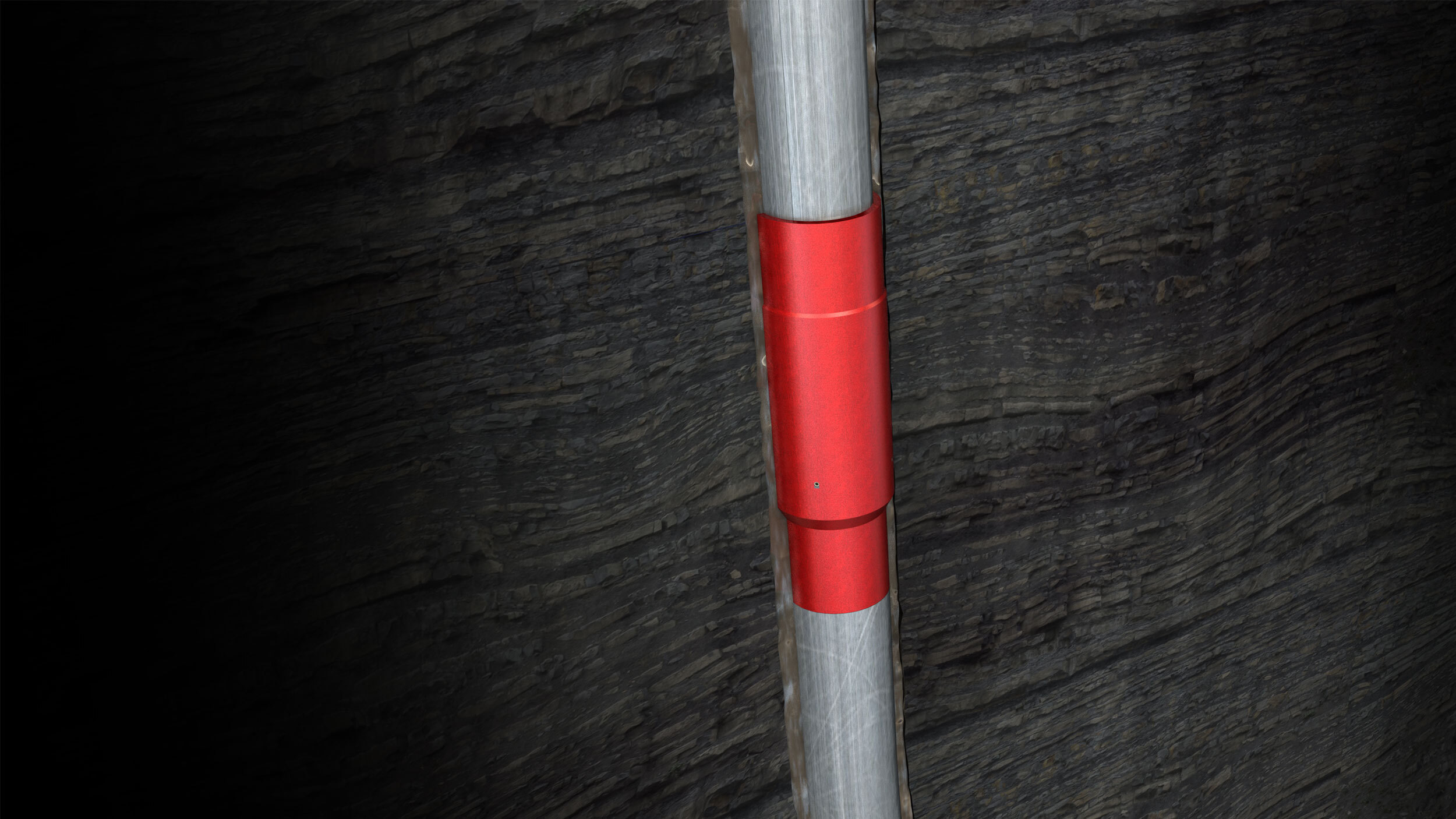

Overcome excessive drag forces to run casing to depth

Talk to an expertThe AirGlide® floatation collar significantly lowers drag and frictional forces to allow casing to get to bottom faster. Through use of an innovative glass disk, the AirGlide floatation collar can lift the casing string away from the wellbore to reduce drag between the casing and the formation to provide improved casing running capabilities. Because the AirGlide floatation collar utilizes an innovative glass disk rather than ceramic parts, there is zero risk of plugoff or damage to float equipment, and the need for a debris catcher is eliminated.

An innovative glass disk handles differential pressures up to 12,500 psi to withstand shocks during handling and well operations but disintegrates into fine, sand-like particles upon activation. These sand-like fragments are easily pumped through float equipment with no risk of plugoff or damage to the equipment, thus leaving a fullbore inner diameter (ID) casing for cementing and completions operations.

An innovative glass disk is capable of handling differential pressures up to 12,500 psi but disintegrates into fine particles upon activation.

0:38

Risk of plugoff or damage to float equipment

PSI maximum differential pressure capability

Debris left after activation