Search

Search

Search

Search

We collaborate and engineer solutions to maximize asset value for our customers.

Explore

We work together with customers and understand that everyone has a role in providing the best solution.

Priority number one. We are focused on our own personal safety as well as the safety of others.

We deliver what we promise. We believe the quality of our service defines who we are.

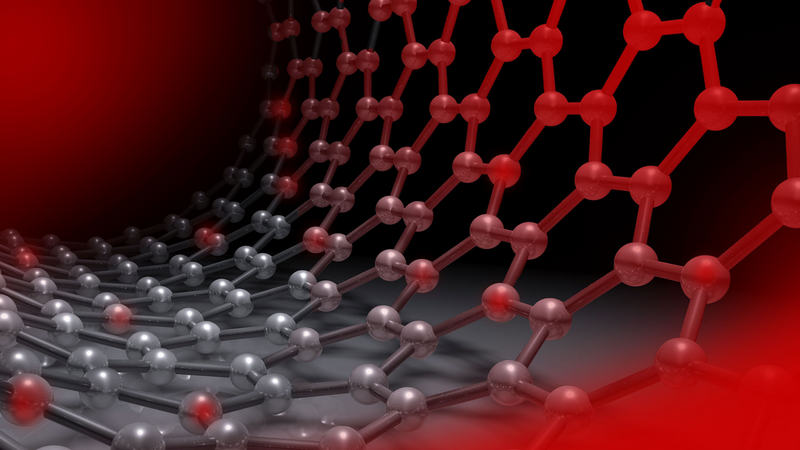

We are resourceful. We are innovative and strive to apply the right technology and solution every time.

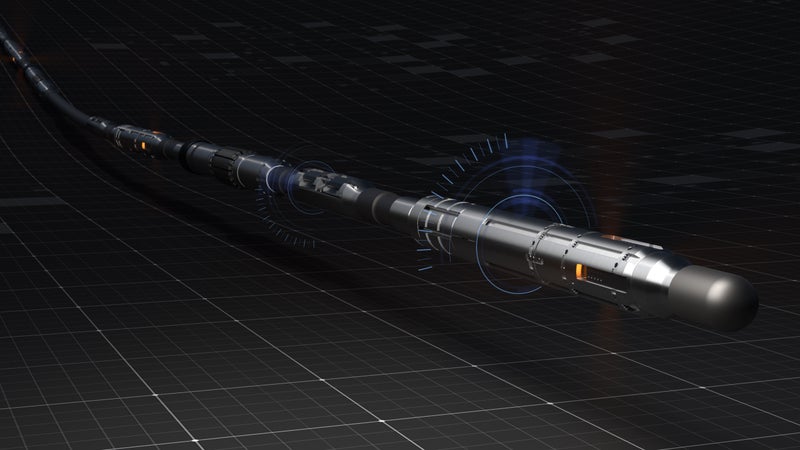

Halliburton unveils SK Well Pages, an all-in-one electric submersible pump workspace, equipping operators with insight to make decisions for optimal production.

Halliburton to provide completions and downhole monitoring services for the Northern Endurance Partnership (NEP) carbon capture and storage (CCS) system.

LIFE2025 brought together 800+ leaders to explore how Halliburton’s digital strategy, AI, and data science are transforming the upstream energy sector.

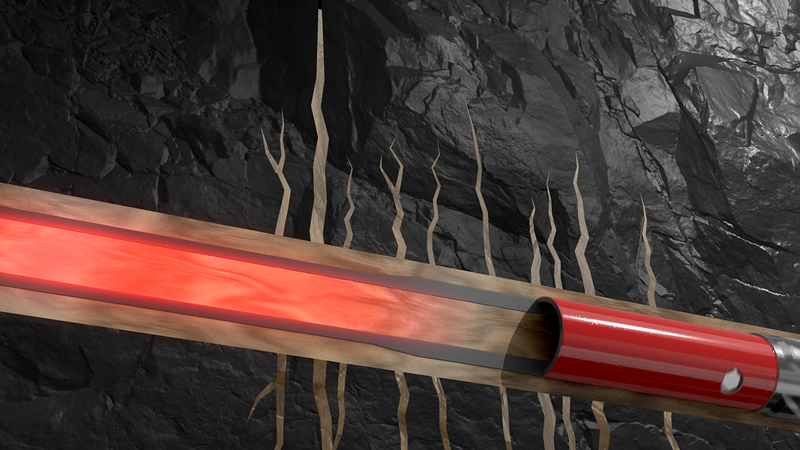

CorrosaCem™ cement system provided a corrosion-resistant solution for injection zones and full isolation of the casing string for future CCUS wells.

Custom solution enables operator to maintain wellbore stability, minimize losses, and complete successful gravel pack in deepwater environment.

Successful installation in Pakistan for a large onshore gas field yielded significant benefits, to include customized flow trims and increased production.

Own your career at Halliburton

02:30