Search

Search

Search

Search

Custom solution enables operator to maintain wellbore stability, minimize losses, and complete successful gravel pack in deepwater environment

Download PDFDeepwater

Develop HPHT drilling fluid tolerant with zinc bromide, an industry first

Offshore

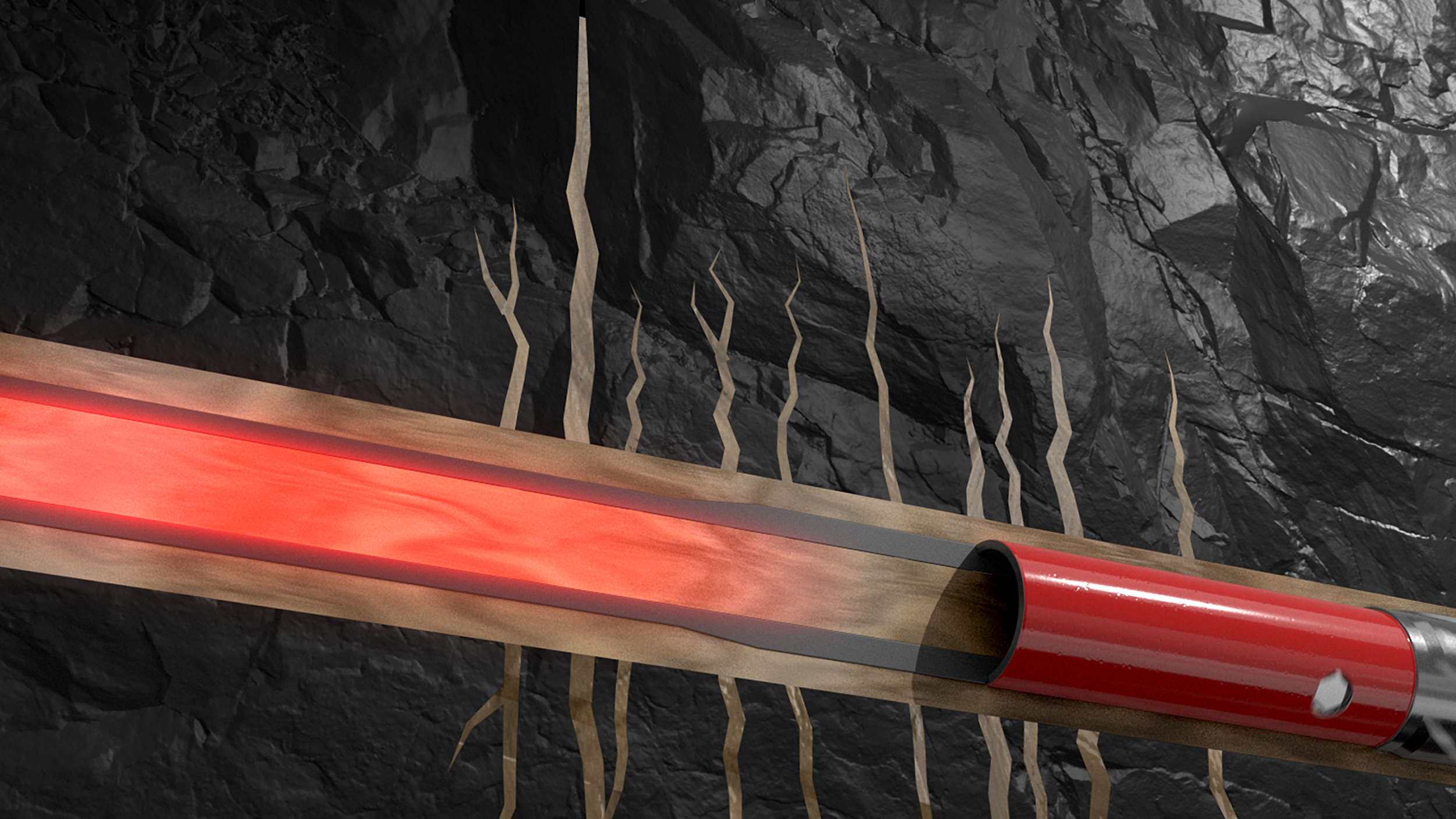

Halliburton engineered and delivered a fluid solution that met the customer’s requirements and reinforced our commitment to provide engineered fluid solutions customized to maximize wellbore value. When an operator requested a high-pressure, high-temperature (HPHT, 344°F BHT) reservoir drilling fluid with a filter cake tolerant with zinc bromide — an industry first — Halliburton developed the BaraFLC® W-1096 chemical additive.

Before deployment, Halliburton conducted laboratory tests to validate the solution’s performance. The customer reviewed and approved the results. The BaraDrilN® X Generation III reservoir drill-in fluid system met the specifications and delivered strong field performance. This solution now serves as the standard for future HPHT operations in the region.

The customer’s well presented several technical challenges. First, the operation demanded a 14.5 ppg density drilling fluid system compatible with zinc bromide — a solution standard systems typically do not support. Additionally, it was essential to maintain wellbore stability and protect the formation throughout the drilling process. The system also needed to minimize fluid losses during drilling to improve efficiency and reduce formation damage. Finally, the fluid had to support a gravel pack and remain stable in the presence of zinc bromide.

Halliburton created a solution with the BaraDrilN® X Generation III reservoir drill-in fluid system and the new BaraFLC® W-1096 polymer.

The system demonstrated exceptional performance under HPHT conditions. It maintained full compatibility with zinc bromide and improved chemical stability throughout the operation. The solution included a 14.7 ppg low-solids screen running fluid and a 14.8 ppg filter cake breaker, both tailored to meet the well’s specific requirements. It also preserved wellbore stability and minimized fluid loss. This contributed to a safer and more efficient operation. Laboratory tests confirmed the system’s effectiveness, leading to the operator’s approval.

Drilled with no adverse effects

Downhole losses

Hour contact time with zinc bromide

ppg density drilling fluid required

The fluid system delivered strong performance across multiple operational metrics. It helped the operator achieve zero downhole losses and maintained exceptional wellbore stability throughout the 69-hour wireline campaign.

Following a 48-hour contact period with zinc bromide, the gravel pack was executed. This demonstrated the fluid’s long-term stability and compatibility. The system also exhibited high gas tolerance and withstood gas levels up to 1,185 units without compromising performance. While drilling through 332 ft of cement, there were no adverse effects on fluid properties. The fluid system remained tolerant of zinc bromide and contributed to improved wellbore stability and integrity.

Specialized drill-in fluids for every reservoir that improve well productivity and reduce formation damage.