Search

Search

Search

Search

We collaborate and engineer solutions to maximize asset value for our customers.

Explore

We work together with customers and understand that everyone has a role in providing the best solution.

Priority number one. We are focused on our own personal safety as well as the safety of others.

We deliver what we promise. We believe the quality of our service defines who we are.

We are resourceful. We are innovative and strive to apply the right technology and solution every time.

Under the agreement, Tidewater’s vessel, North Pomor, will be transformed into an advanced stimulation vessel designed to efficiently deliver offshore well stimulation services in the North Sea.

Halliburton unveils SK Well Pages, an all-in-one electric submersible pump workspace, equipping operators with insight to make decisions for optimal production.

Halliburton to provide completions and downhole monitoring services for the Northern Endurance Partnership (NEP) carbon capture and storage (CCS) system.

Halliburton deployed ROCS 2.0 in Gulf of America for safer, faster deepwater completion at 8,458 ft, cutting rig time and boosting control.

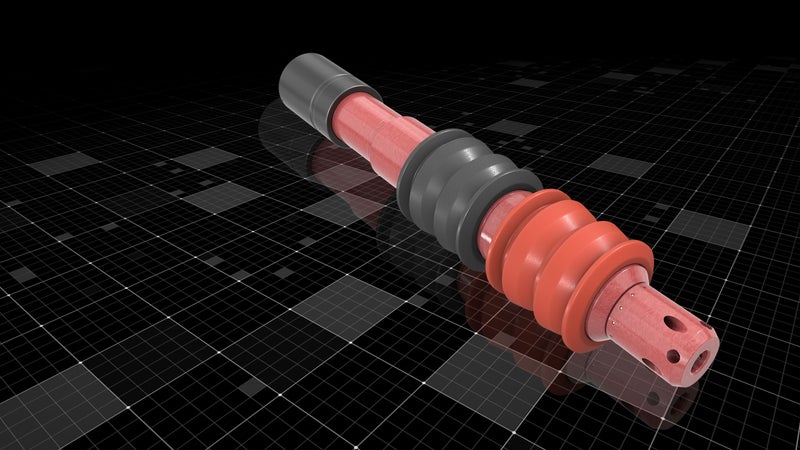

The dual-plug SSR-II™ cement plug system delivers an improved annular cement barrier for a production liner equipped with a VersaFlex® expandable liner hanger.

Deployed for the first time in Pakistan, solution delivers durability and drilling efficiency in complex formation for United Energy Pakistan Limited.

Own your career at Halliburton

02:30