Search

Search

Search

Search

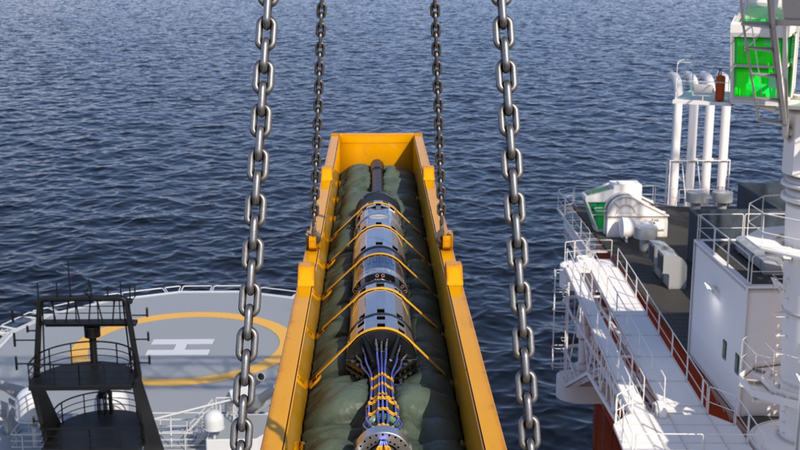

Completion and tubing hanger installed at 8,458 ft in the Gulf of America

Download PDFDeepwater

Simplify subsea operations, reduce risk, and improve control

Gulf of America

An operator sought to overcome key limitations of traditional umbilical systems, such as:

Deploy Optime, a Halliburton service, ROCS 2.0 technology to:

To fulfill a complex deepwater project safely and efficiently, a Gulf of America operator turned to Halliburton for subsea completions expertise and technology. The operator aimed to simplify its subsea operations, reduce risk, and improve control in extreme water depths through the use of the industry-first, umbilical-less Remote Operated Control System (ROCS). Halliburton collaborated with the operator to design and execute a record-breaking tubing hanger installation and deployed the deepest umbilical-less completion landing string globally, at 8,458 ft water depth.

Operators' strong focus on safety and efficiency is driving increased demand for more effective and streamlined deepwater completions and interventions. Traditionally, subsea operations rely on Intervention Workover Control Systems (IWOCS) to deploy and install deepwater tubing hangers and completions. These systems involve large, heavy multi-core umbilicals, reelers, and hydraulic power units (HPUs), all of which must be mobilized offshore.

The umbilical often represents the weakest link in offshore operations. Adverse weather or unexpected tubing movement can damage this expensive component, forcing operators to halt operations for repair or replacement—resulting in rig downtime and increased costs.

Beyond operational risks, IWOCS umbilicals and reelers introduce significant safety hazards, including critical lifts, suspended overhead loads, high-pressure lines, rotating equipment, and limited control and feedback. The sheer size of the equipment and limited real-time control hinder operators’ ability to make timely decisions.

Faced with these challenges, the operator sought a solution that would minimize equipment footprint, enhance safety, and accelerate operations—without compromising control or reliability.

Halliburton delivered a smarter, safer solution to traditional umbilicals: ROCS 2.0 technology, developed in collaboration with Optime, a Halliburton service. This umbilical-less system replaces conventional hydraulic setups with a compact control system, engineered for deepwater reliability and precision. ROCS uses high-resolution pressure sensors, solenoid-operated valves, and directional control valves to provide better control, visibility, and flexibility throughout the tubing hanger installation operation. These features allow more precise control of the tubing hanger running tool (THRT) and downhole (DH) functions.

For the customer, this meant a faster, safer deployment with fewer components to manage. The customer gained improved real-time control through high-resolution pressure sensors and precision valves and a safer environment through the elimination of large umbilicals, suspended loads, and high-pressure HPUs.

ft water depth

faster run-in-hole speed

stands/hour

Reduced deck testing and backloading time

The operator not only met its project goals but also set a new benchmark for deepwater completions. It achieved the deepest umbilical-less completion landing string ever deployed globally at 8,458 ft. The deployment delivered significant time savings through reduced rig time and a 2x faster run-in-hole speed that reached 12 stands/hour. It reduced deck testing and backloading time by 75%.

The simplified equipment setup and improved safety for offshore personnel reduced operational risk during deployment. In addition, the more rigid hydraulic system increased control line testing efficiency and supported a smaller footprint.

With the integration of ROCS, Halliburton delivered a smarter, more agile subsea completions approach, customized to meet the customer’s operational goals. This success reflects the Halliburton commitment to designing flexible, outcome-driven technologies that help customers operate with greater speed, safety, and confidence, especially in challenging offshore environments.

Minimize complexity and maximize flexibility with umbilical-less subsea tubing hanger installation systems