Search

Search

Search

Search

Casing-while-drilling bit helps United Energy Pakistan Limited achieve record ROP

Download PDFMature Fields

Volcanic rock limits ROP and delays reaching total depth

Onshore Pakistan

In a complex onshore drilling environment, a leading operator aimed to improve drilling efficiency, reduce nonproductive time (NPT), and reach section total depth (TD) in a single run. The operation required navigating complex lithology, which included a variety of rock types. It required a durable and high-performing bit solution. To meet these goals, the team implemented advanced drilling technology designed to deliver consistent performance across complex formations.

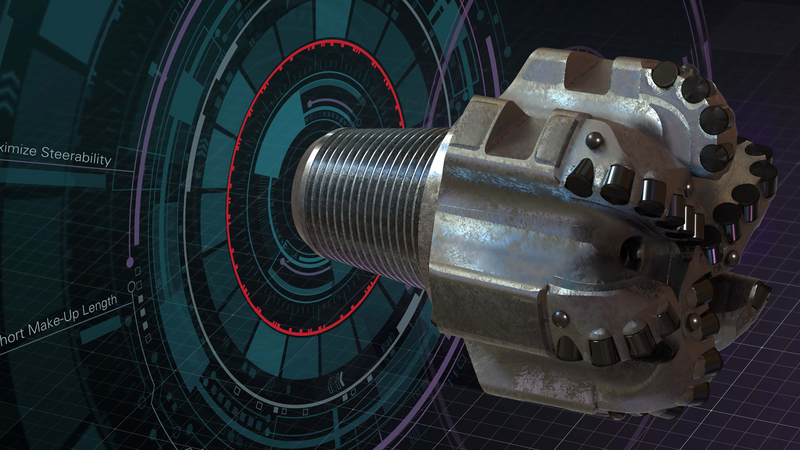

United Energy Pakistan Limited (UEPL) encountered significant challenges while drilling the 12 ¼-in. section. These challenges included the need to maintain bit durability and achieve a high rate of penetration (ROP) through a complex sequence of shale, sandstone, claystone, and abrasive volcanic rock. Conventional bits often led to increased bit trips and operational delays. UEPL needed a reliable casing-while-drilling solution that could withstand harsh downhole conditions, minimize inefficiencies, and enable a smooth and efficient transition to the next drilling phase.

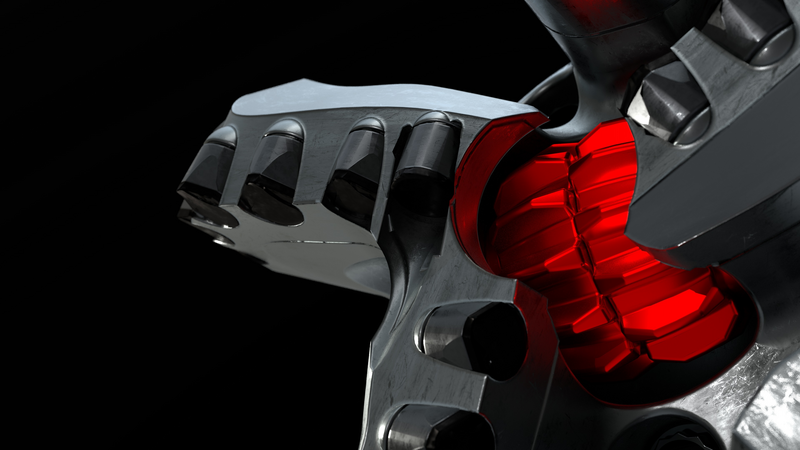

UEPL and Halliburton collaborated to engineer an innovative solution with the first implementation of a casing-while-drilling bit. Designed with an advanced cutting structure and a customized profile, this technology is engineered to maximize performance and help reach section TD. These features work together to deliver stability, durability, and drilling efficiency, while optimizing the cutting structure to handle both soft and hard lithologies.

ft/hr reached on-bottom ROP

Faster compared to offset well

Rig time saved

Drilled into volcanic formation

The casing-while-drilling bit improved drilling performance across multiple metrics. It reached an on-bottom ROP of 164.79 ft/hr, which was 37% faster than the offset well. The bit drilled 52 ft into the volcanic formation and reached TD without issues. The operation successfully ran the 9 5/8-in. casing to TD. In the next phase, the following bit completed the drill-out and continued section drilling without complications.

The casing-while-drilling bit has become the performance benchmark for the customer in the region. Due to its success, the customer expanded its use to additional locations and across various casing sizes. This approach saved valuable rig time, enabled record ROP to reach TD, and achieved a smooth drill-out.

Directional drill bits designed for high build rates in curve and lateral applications.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.

Halliburton Crush & Shear™ hybrid drill bit technology optimally places the PDC and rolling elements increasing drilling efficiency.