Search

Search

Search

Search

February 8, 2021

An increasing number of producing fields are exhibiting late life symptoms like aging well stocks, high water cut, and flow assurance issues, all of which can lead to well integrity issues such as high casing pressure, mechanical failures, or corrosion problems. Many gas fields report high CO2 and H2S content which can be challenges for pipe metallurgy and reliability. Faced with increasingly stringent regulations, a shrinking experienced workforce, and the need to control costs, E&P operators are getting serious about well integrity management (WIM).

To be sure, well integrity has been a key area of focus in the industry since early 2000 when regulators and leading operators started recognizing the magnitude of problems posed by well integrity risks. Consider the following:

Many international oil companies and a few large national oil companies launched their own WIM initiatives and worked towards pushing them into their producing assets. The rest of the industry, however, moved relatively slowly to catch up with their peers.

The post-2014 price collapse strengthened focus on WIM when E&P companies across the board started to look for cost-effective ways to improve the recovery from the existing fields. Wells that were shut in or impaired due to well integrity issues became obvious opportunities for production gain. These issues also drew attention to the need for better processes and systems to improve well integrity performance.

Over the past few years, we have seen an accelerating adoption of digital WIM systems by E&P companies looking to implement exception-based integrity management, drive better risk assessment, standardize their WIM processes, and automate workflows.

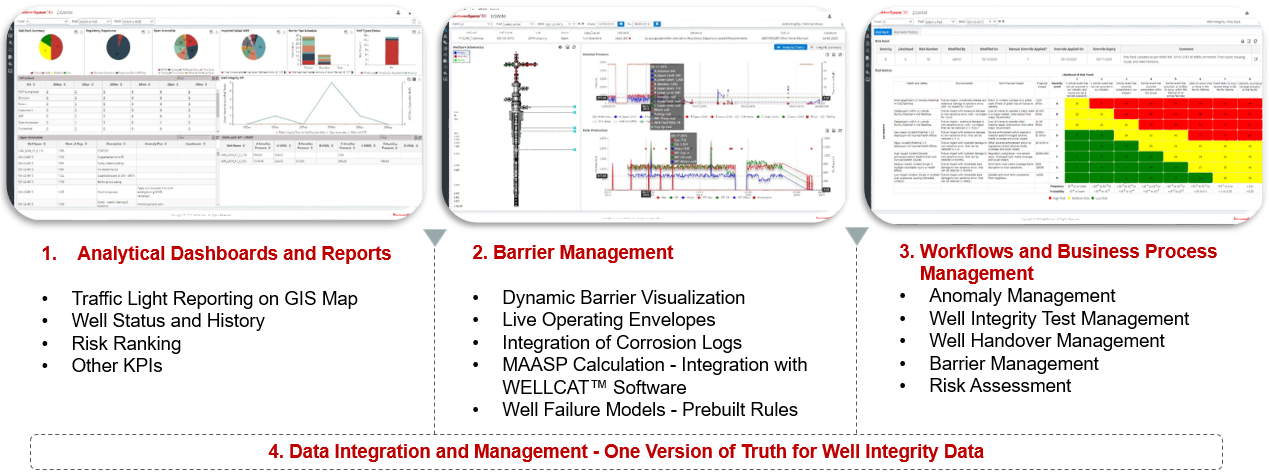

DecisionSpace® Well Integrity Management software is designed to help minimize risks and associated production losses by streamlining well integrity monitoring and analysis. With automated and integrated workflows, it delivers rapid diagnosis of well barrier elements to spot well integrity risks faster and execute preventive and corrective maintenance in time. End users can be aided in rapidly identifying high-risk wells, taking corrective actions faster, and mitigating issues to maximize well availability.

The combination of best-in-class engineering, flexibility for customization, and future readiness provides a unique value proposition to E&P companies.

Best-in-class Engineering

The traditional practice of using standard operating envelope calculations (e.g., maximum allowable operating pressure) doesn’t always fully address complex and intertwined well integrity risk factors such as well head movement, temperature and pressure effects, casing wear, zonal isolation, and tubing/casing safety factor (SPE 164230. March 2013). These are additional elements to consider in managing the integrity of complex and wells such as high-pressure-high-temperature, high H2S, or deep-water wells.

Integration with WELLCAT™ software gives DecisionSpace Well Integrity Management software a superior ability to detect the downhole integrity risks early on and help prevent downtime or environmental hazards. Over 80% of the operators globally trust WELLCAT for its advanced engineering calculations required for well design.

Workflows in DecisionSpace Well Integrity Management software automatically fetch engineering calculations to continuously update the Stress and Load envelopes of the tubulars and alert end users if actual operating conditions of the wells trend closer to those envelopes. This approach gives end users a better understanding of how changing operating conditions impact the integrity of the wells, which is not always possible with the simple MAASP-based operating envelopes.

Flexibility for Customization

No two oilfields are the same and neither are their requirements for well integrity management solution. When software can’t easily adapt to the unique context of the oilfield operations, it can force E&P companies to adjust to the constraints of the software, even at the cost of sacrificing the institutional knowledge or best practices. The result can be lost opportunity for innovation and buy-in from the users.

DecisionSpace Well Integrity Management software is built on the E&P industry’s fully open, interoperable DecisionSpace platform which offers E&P companies flexibility for customization and the ability to create well integrity management solutions tailored to their unique business processes and IT environment.

Future Readiness

Any WIM software needs to work in a heterogenous technology environment. It needs to talk to a multitude of data sources and adjust to changing modes of operations or expansion. An inability to adjust adds to architectural complexity and cost of ownership, and E&P companies may need to procure additional technologies to keep up with the growing needs of their business.

DecisionSpace Well Integrity Management software can help solve these problems.

The underlying DecisionSpace platform connects with a variety of data sources and accommodates evolving workflows, visualization, and analytical needs without requiring additional technologies. The platform is the foundation to all Halliburton’s digital offerings and is supported by long-term product roadmaps and R&D investments. With a track record of successful implementations globally, it brings to E&P companies the assurance of referenceable quality and future readiness.

REFERENCES

Oil & Gas Journal. October 11, 2004. API committee addresses annular casing pressure management .

OnePetro. October 28, 2009. Well-Integrity Issues Offshore Norway.

Oil & Gas Authority. 2018. Wells Insight Report.

NORSOK STANDARD D-010. Rev. 3, August 2004. Well integrity in drilling and well operations.

ISO. March 2017. ISO 16530-1:2017. Petroleum and natural gas industries — Well integrity — Part 1: Life cycle governance.

Production Technology. Islam Fetoui. October 14, 2017. 5 things you should know about the ISO 16530-1 Well Integrity Standard.

One Petro. Robello Samuel. March 10, 2013. Well Integrity Management System (WIMS): Coupled Engineering Analysis. Paper presented at the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, March 2013. Paper Number: SPE-164230-MS.