Search

Search

Search

Search

True to design, SP™ TRSV delivers superior performance and remains fully functional after 21 years downhole

Download PDFWell shut-in six years due to integrity issues

Angola

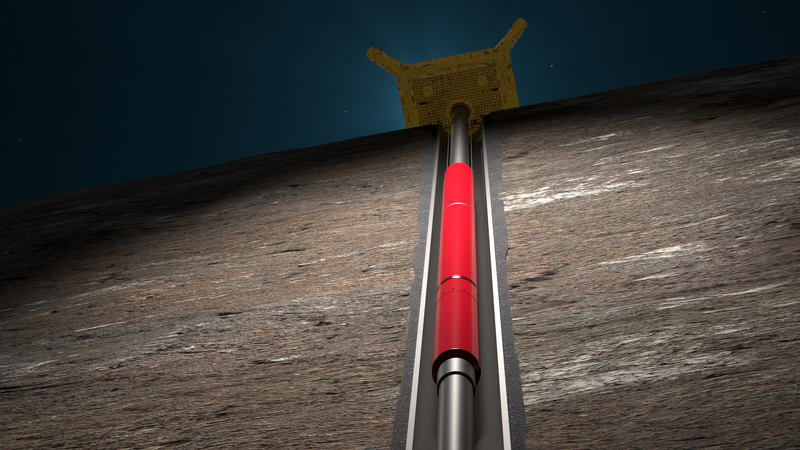

In 2001, Halliburton installed an SP™ tubing-retrievable safety valve (TRSV) in a subsea gas injector well drilled and completed for an operator in Angola in a water depth of approximately 4,429 feet (1350 meters). The SP TRSV was closed in 2016 due to well integrity issues. On returning to the well in 2022 to remove hydrates under the Christmas tree cap, the operator observed multiple barriers in a degraded state.

With the well expected to be taking losses, the choice of bridge plug was crucial to ensure its ability to set. Bridge plug selection also had to account for TRSV operation uncertainty after six years without functioning due to the reduced inner diameter (ID) if a hold open sleeve was required.

Integrated rig operations were performed to restore the well integrity, clear hydrates and test all barriers.

SP TRSV was installed

ft water depth

well closed due to integrity

later reopened and SP TRSV was fully functional

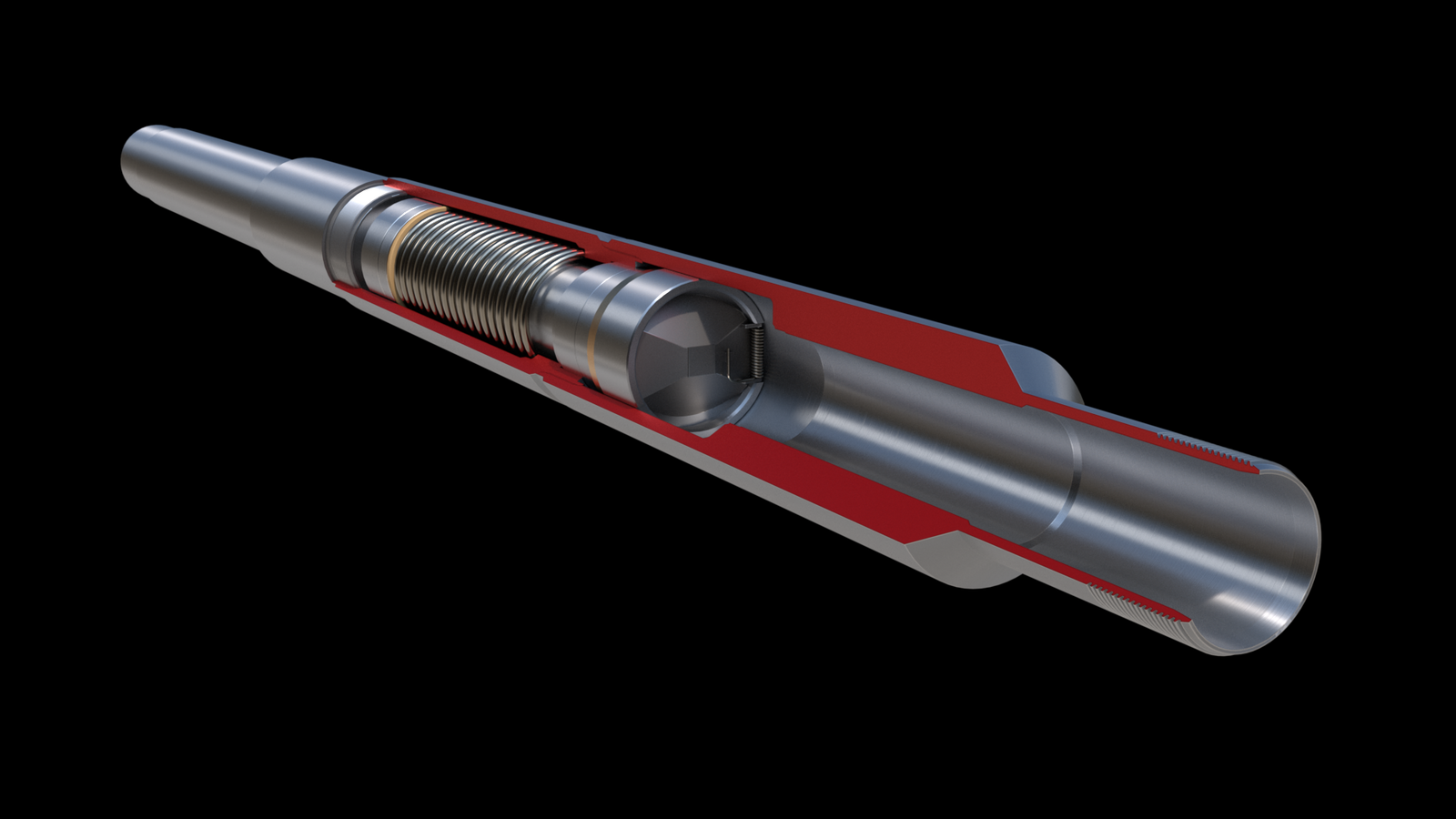

During intervention operations, the Halliburton Angola team function tested the SP™ TRSV several times to confirm valve operation and successfully performed inflow testing with its metal-to-metal sealing flapper and seat. The SP TRSV remains in service and the operator avoided additional intervention time and costs associated with valve replacement.

The ability to function after 21 years in the well demonstrates the SP TRSV’s superior performance and reliability.

Halliburton tubing-retrievable and wireline-retrievable subsurface safety valves are a field-proven solution for operators.

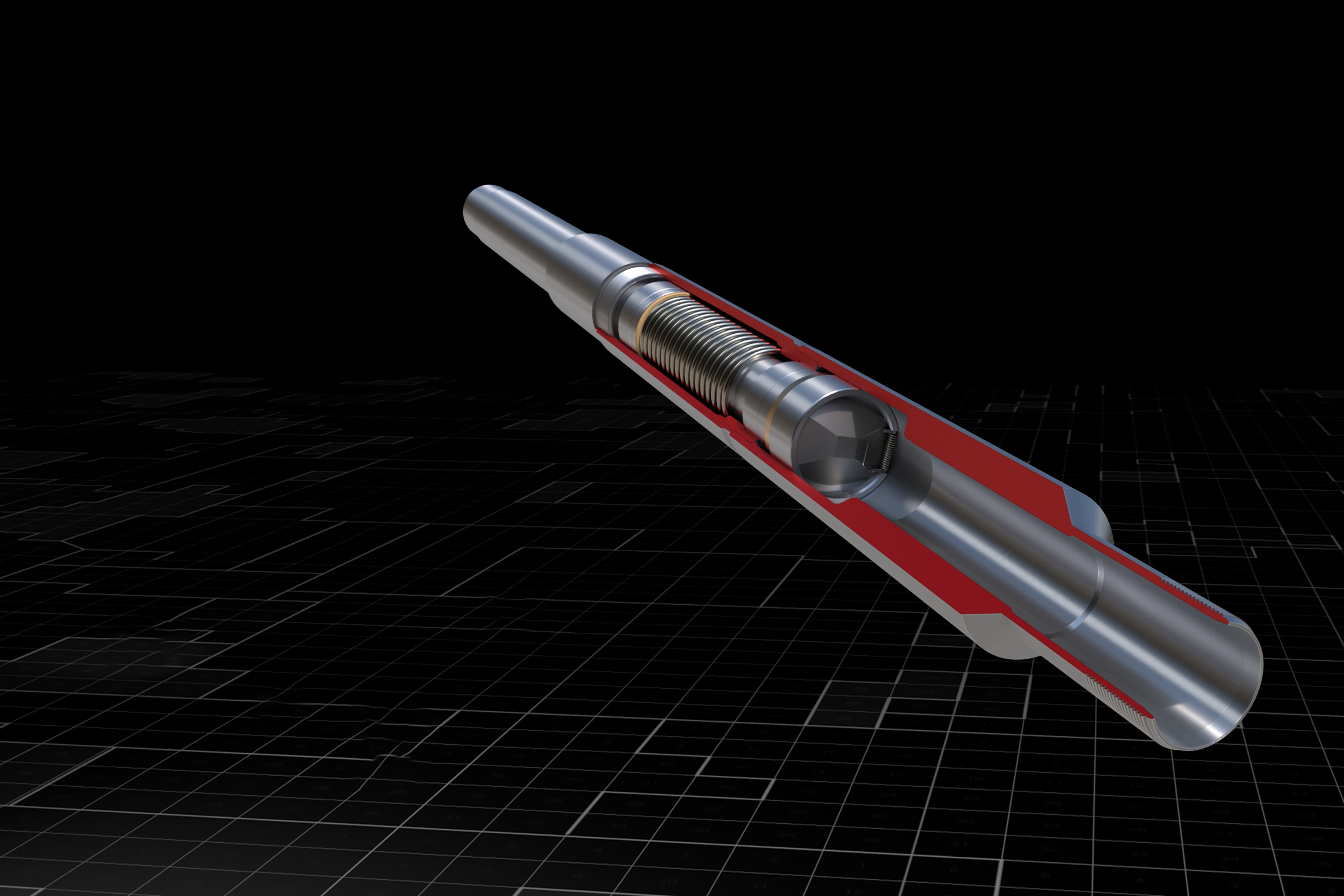

A single rod-piston non-elastomer flapper valve designed for hostile environments and extended life applications where ultimate reliability is required.