Search

Search

Search

Search

Unconventionals

Formulating a high-density WBM kill mud

Parva Negra Field, Neuquén, Argentina

An operator in Argentina’s Parva Negra field planned to re-enter and deepen an extended-reach well that had been temporarily abandoned in 2015. A high-density drilling fluid would be needed to maintain well control. The ability to control equivalent circulating density (ECD) and optimize rheological properties would be critical to the success of this exploratory well operation.

Total measured depth (MD) on the original well was 2,032 meters (6,667 feet) and the bottomhole temperature was 199°F (93°C). The objective for the re-entry was to drill through the Quintuco and Vaca Muerta formations. A managed pressure drilling (MPD) system was installed to help provide an adequate ECD without increasing the surface mud weight.

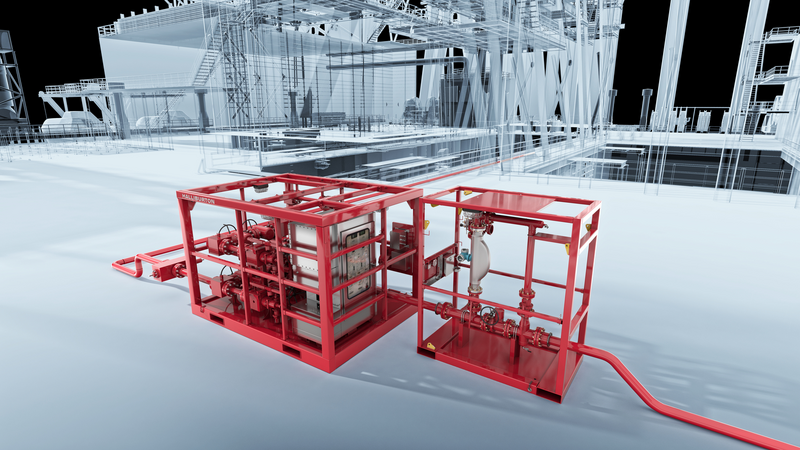

The water-based mud (WBM) selected for the operation was formulated with a wetting agent and CARBONOX® filtration control agent. Using a wetting agent can alter the surface tension on dispersed particles in WBM, leading to lower flow properties and improved ECD management.

A saltwater and gas influx occurred in the Vaca Muerta formation at 2,214 meters (7,264 feet). The mud density was increased from 2.10 sg to 2.21 sg (17.5 lb/gal to 18.4 lb/ gal) as drilling continued with the MPD system. The operator wanted to proceed with well abandonment, but a higher-density kill mud would be required to complete this operation.

Baroid technical personnel evaluated sources for the hematite weighting agent in Argentina. The use of hematite instead of barite for the ultra-high-density kill mud required a Management of Change (MOC) document to analyze potential risks and to address logistics concerns about obtaining the necessary quantities of hematite needed to perform the job without delays. The document was prepared through collaboration between the operator’s representatives and the Baroid technical team.

Hematite samples from three different suppliers were tested with the water-based CARBONOX system. Extensive analysis was completed at the Halliburton lab in Neuquén and at the rigsite to optimize the rheological properties (Table 1). The kill mud must provide sufficient suspension capacity to support a mud weight of 2.55 sg (21.3 lb/gal) while exhibiting the lowest possible plastic viscosity, yield point, and gel strength values (properties shown in the table). This would help minimize the ECD increase during the kill operation.

Particle size distribution (PSD) testing was also performed on the hematite samples to determine which candidate was best for ECD management (Table 2).

lb/gal Displaced

USD Cost-Savings

Nonproductive Time (NPT)

The optimized WBM formulation, weighted with hematite to 2.55 sg (21.3 lb/gal), was displaced into the wellbore prior to commencing the abandonment operation. This was the highest WBM mud weight used in this area for well control.

The operation helped reduce rig time by approximately three days, resulting in an estimated cost savings of USD 108,000.

The abandonment procedure was carried out successfully through the collaboration of all service companies under the operator’s leadership. Zero nonproductive time (NPT) was recorded.

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.

Addressing the toughest issues in well intervention, Halliburton offers services to extend well life, improve performance, and limit downtimes.

Navigate challenging pressure windows between pore and fracture pressure in complex wells to reduce drilling days and NPT.

We customize filtration solutions for every job, so you get targeted options to help you maximize filtration and ensure environmental compliance