Search

Search

Search

Search

Mature Fields

Unconventional

Perform multistage stimulation of an offshore multilateral well

Kazakhstan

The operator of an offshore field in the Middle East required implementation of several cost-effective technologies to help increase production from a depleted carbonate formation. To address challenges and maximize contact with the pay zone, Halliburton listened to the operator’s requirements and provided a dual-lateral well design with horizontal branches, and multistage acid stimulation to improve the well productivity index at a given drawdown value.

Halliburton and the operator collaborated during the project design phase and identified post-stimulation fluid loss as a potential risk, which can jeopardize the ability to safely install the upper intelligent completion. Loss control materials/fluids would likely cause formation damage in the treated zone and therefore were not an option in this case. Halliburton suggested an off-the-shelf EGF expendable flapper valve as the fluid loss control device (FLCD) for the main bore. After installation of the upper completion, this FLCD can be deactivated (opened) using a dedicated intervention method to help ensure a clear flow path for hydrocarbon production. However, the lack of mechanical access to the lateral branch on the other side presented additional challenges that necessitated an innovative solution.

Because acid stimulation in offshore environments requires significant investment, Halliburton engineers proposed a competent zonal isolation and pinpoint placement of the treatment fluids to ensure operational success and maximized production results. Accurate placement of the openhole isolation packers at precise locations necessitated a tight tolerance on the setting depth. Thus, a liner hanger system able to convey the lower completion to the planned setting depth was also crucial.

In addition, frac sleeves with a clear opening signature were necessary to expedite operations and avoid uncertainty during treatment, which can lead to long delays for additional analysis and approval to pump the corresponding stage treatment.

Halliburton tailored a temporary FLCD for the lateral branch, and testing was conducted to verify its performance under specific well conditions. This device provided a means to control fluid losses into the stimulated zones so the intelligent completion could be installed without complications.

Swellpacker isolation systems were included in the lower completion design to provide competent compartmentalization along the open hole. The seal element length and ability to conform to wellbore inner diameter (ID) irregularities help ensure reliable hydraulic isolation in openhole applications.

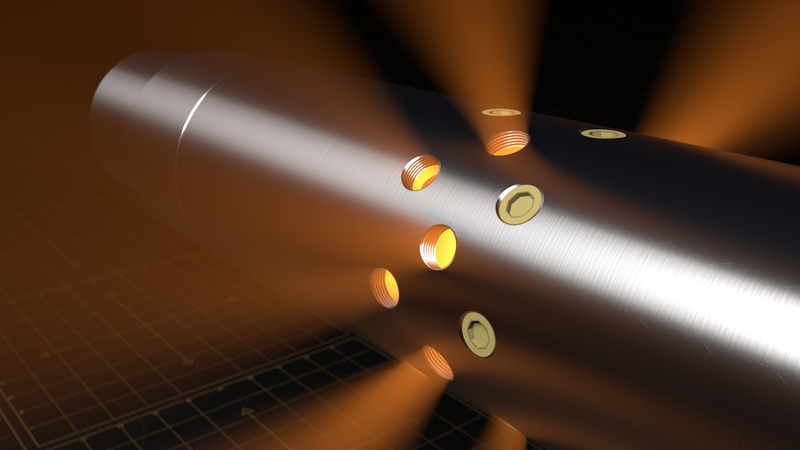

RapidSuite frac sleeve systems, including RapidStage® frac systems and RapidStart® initiator sleeves, were installed in each lateral and provided a clear opening signature, reducing uncertainty and allowing the operator to quickly decide whether to pump treatment downhole, without conducting additional time-consuming analysis.

Finally, to help enable successful, trouble-free conveyance of the lower completion to the planned setting depth, the VersaFlex expandable liner hanger with rupture disk feature was installed at near-horizontal depth.

ball action signature

stages of flawless stimulation operation performed

losses of Intelligent completion string installed

The temporary FLCD in the lateral branch provided effective fluid loss management and allowed for safe installation of the intelligent completion. Flowback operations were performed without restriction, reducing flowback time by an average of six days per branch and providing significant rig cost savings per branch. Additionally, the overall efficiency of operations helped maximize asset value and reduce the time to production, representing a quicker return on investment for the operator.

During multistage stimulation, the RapidStage® sleeve systems delivered an unmistakable ball action signature in 100% of the stages, increasing operator confidence and allowing the treatment plan to continue without delay. Swellpacker systems provided competent zonal isolation between stages, enabling pinpoint placement of treatment. In addition, the VersaFlex liner hanger successfully conveyed the lower completion to the desired setting depth at a near-horizontal inclination.

The RapidStage Frac Sleeve system helps ensure the stimulation treatment covers the targeted areas in the wellbore and maximizes the stimulated reservoir area

Download Data SheetAchieve complete zonal isolation

VersaFlex expandable liner hanger is offered as a single unit containing an integral upper tieback receptacle, an expandable liner hanger and a setting/running sleeve.

Download Data Sheet

RapidStage® frac sleeve systems optimize multistage completions by accurately placing stimulation treatments without intervention.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications