Search

Search

Search

Search

Customized GeoTech® fixed cutter bit drills vertical well at higher ROP than competitor offset wells

Download PDFMature Fields

Engineering a customized bit solution to drill a vertical well at a higher ROP

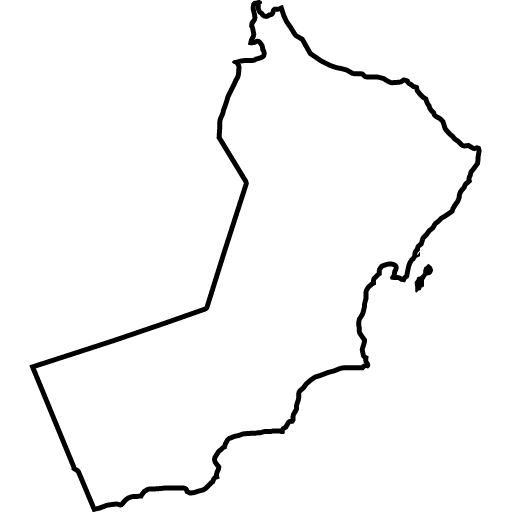

Oman, Western Asia

For a vertical well, engineer a customized bit that would be capable of:

Engineered custom bit design, utilizing DatCI℠ process and the following:

An operator drilling development fields in Oman needed to drill shoe-to-shoe in a vertical well from the Sharji to Dhruma formation at a high rate of penetration (ROP). A dysfunction analysis summary of offset wells showed that stick slip was a potential issue that required a customized bit design to optimize performance. Halliburton Drill Bits and Services used the collaborative Design at the Customer Interface (DatCISM) process to quickly find a unique solution, leveraging application intelligence and ensuring superior execution.

The resulting Halliburton engineered bit design consisted of several components configured to deliver high-performance drilling. The foundation technology, GeoTech® fixed cutter PDC bit, was enhanced by the Cerebro™ in-bit electronics data capture system – capable of continuous high-frequency data capture (1,000 Hz) – to optimize drilling parameters and mitigate drilling dysfunction. To increase point loading and efficiently fracture rock, the Shyfter™ R2 active element (the most durable of the Shyfter active line) was added; its impact arrestors and long gauge helped minimize bit instability. And to optimize cuttings removal for increased ROP, dual-action hydraulics was employed for more efficient heat removal at the PDC bit, while reducing stagnation zones across the flow between blades.

The innovative, high-performance bit design enabled the operator to successfully drill the 863-meter (2,831-foot) section at an average ROP of approximately 37 meters/hour (121 feet/hour). This represented a 58 percent improvement in ROP over the same field average and 16 percent higher than the recent best offset. Additional achievements included saving 16 hours of rig time compared to the offset wells, reaching the section total depth (TD) ahead of plan by 1.5 days, and saving USD 15,870 in just one run.

Hours of Rig Time Saved

Improvement in ROP

USD Saved in One Run