Search

Search

Search

Search

Halliburton multilateral services and intelligent completions optimizes oil production

Download PDFMature Fields

Increase reservoir contact and maximize oil production in the Middle East

Middle East

An operator wanted to increase reservoir contact in order to realize an immediate increase in oil production.

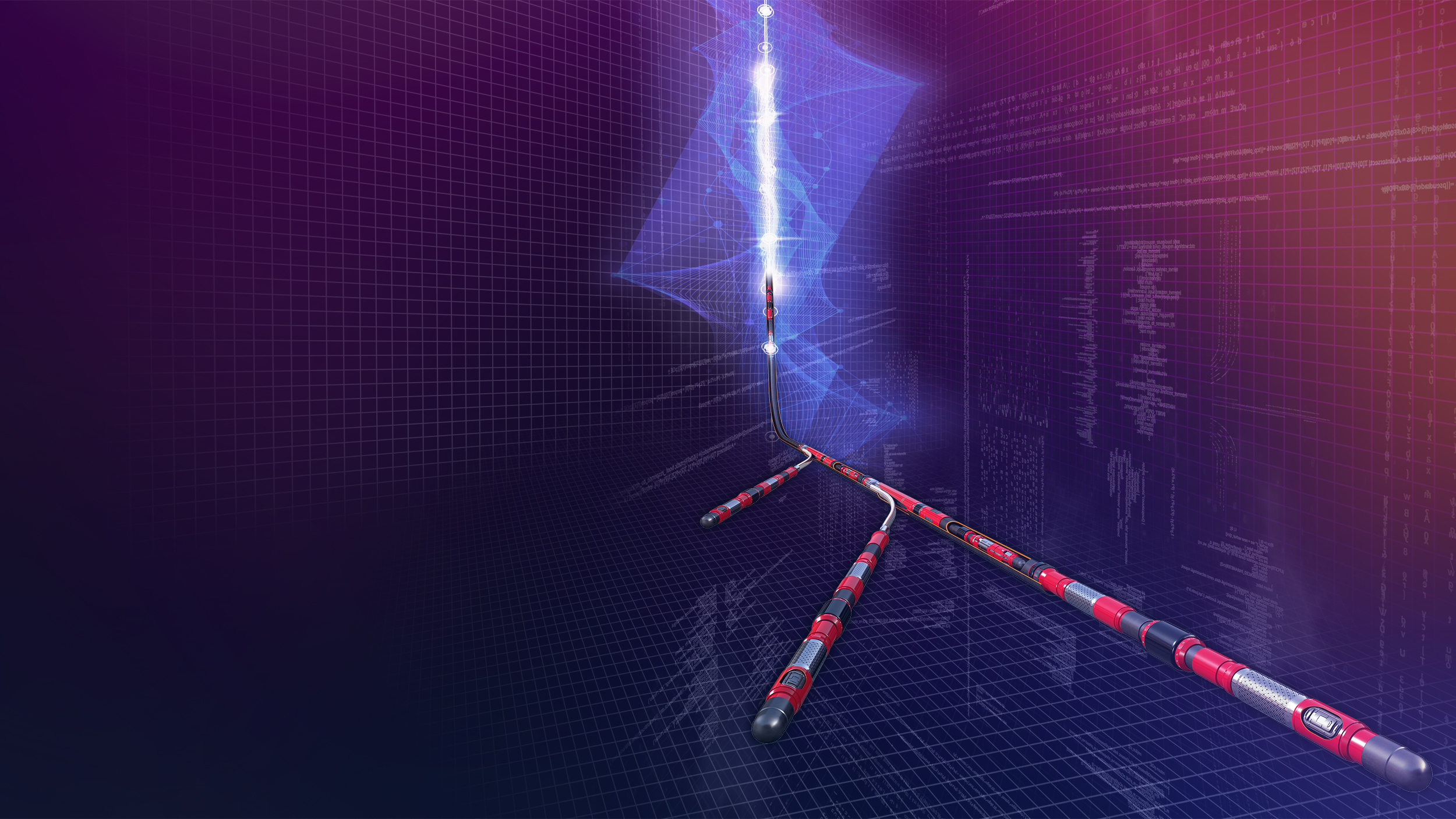

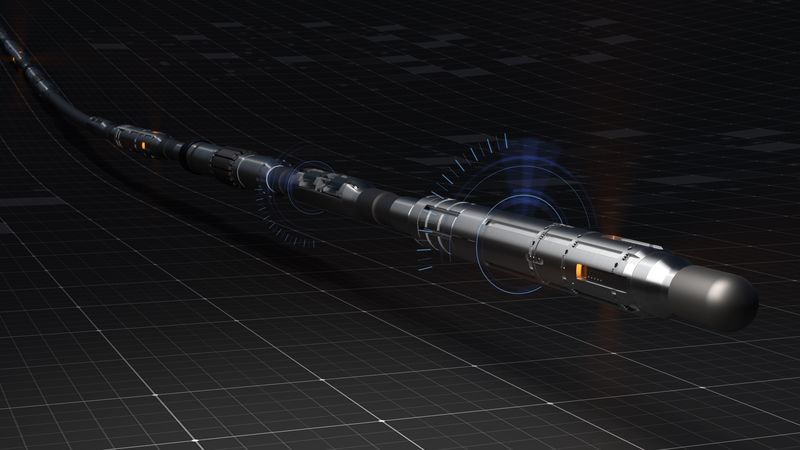

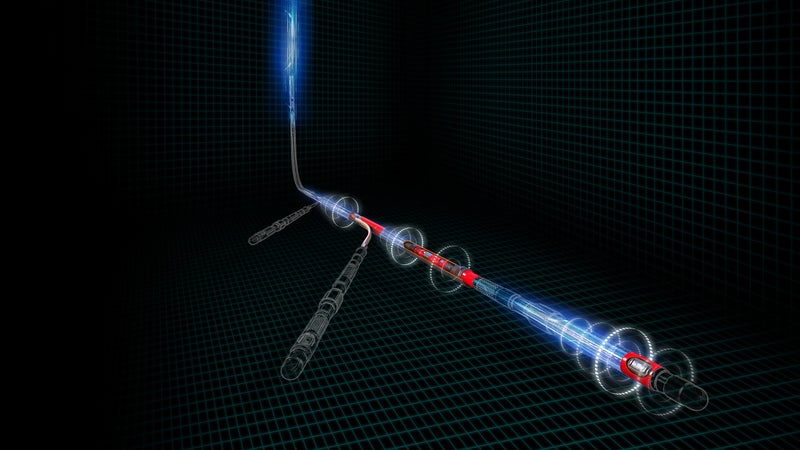

Halliburton recommended an integrated solution that included both multilateral services and intelligent completions technology. The MillRite milled exit multilateral system and SmartWell interval control valve helped maximize reservoir exposure and optimize increased production of the well.

As a result, the dual-lateral well more than doubled its reservoir contact, helping maximize the production rate. The immediate increase in production was coupled with an increase in the longevity of the well, since it could now be remotely controlled and monitored in both laterals from the surface.

A Middle East operator was looking to increase production on an offshore dual-lateral well. They felt by increasing reservoir contact, they would be able to maximize the value of the asset in terms of longevity and oil production. Finding a solution that would limit intervention, and therefore rig time and cost, was invaluable.

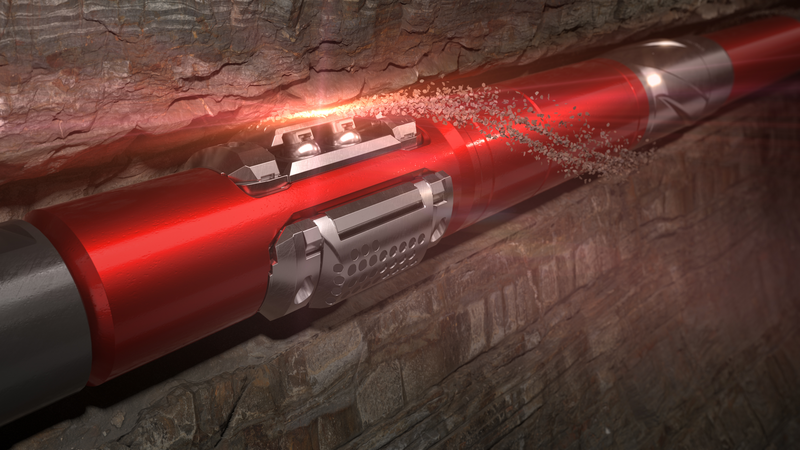

Halliburton Multilateral Services installed a latch coupling in the main bore casing string at 5,631 ft (1,716 m) measured depth (MD), followed by drilling and completing the main bore section with screens containing inflow devices and swellable packers. The MillRite track-guided milling machine, anchored in the latch coupling, milled a casing exit with precisely controlled window geometry. The aperture was opened to full gauge, creating a 15 ft window, with the MillRite one-trip whipstock system.

A rotary steerable system (RSS) drilled the 1,121 ft (342 m) lateral to 6,760 ft (2,033 m) MD, and the liner was set and cemented up to the junction. After the main bore casing and the lateral liner were cleaned out, the RSS drilled the 6 1/8-in. horizontal section to the target depth of 9,990 ft (3,045 m) MD. Screens with inflow control devices along with swellable packers were installed in the lateral.

Halliburton next performed the washover (recovery of the whipstock and the part of the transition joint protruding into the main bore), completing the TAML Level 4 multilateral junction in one operation. A TAML Level 4 junction is defined as having both the main bore and lateral bore cased and cemented at the junction with full bore access. The MillRite system created the multilateral junction successfully in a minimal number of trips without incurring any nonproductive time.

Halliburton interval control valves (ICV) with the Accu-Pulse™ control module and ROC™ permanent downhole gauges were installed in the mainbore. ICVs are remotely-operated downhole valves used to control flow into or out of the two intervals. ROC electronic pressure and temperature gauges continuously monitor downhole parameters and transmit data to surface in real time, while the ICV, in conjunction with the Accu-Pulse module, helps to optimize production from the different laterals. SmartWell interval control valves have 10 discrete choke settings and can be hydraulically operated from surface to optimize the production from each lateral during the life of the well. The operator was now able to monitor and optimize the inflow from both laterals remotely from surface without downhole well intervention.

ft window created by the MillRite one-trip whipstock

level 4 more than doubled the reservoir area

Feet target depth reached

The TAML Level 4 dual-lateral well more than doubled the reservoir contact area compared to drilling and completing a conventional single-lateral well, and doubled the production rate. Compared to the rig time it takes to drill two single-lateral wells, a dual-lateral well requires much less rig time, and negates the duplication of all up-hole well construction costs, including drilling, casing, cementing and fluids costs.

One of the primary benefits of multilateral junction systems is full-bore access to the lower main bore and into the lateral. By maintaining full gauge past the junction, the choice of completion equipment is not restricted. Another significant benefit, the latch coupling, continues to act as a permanent downhole landing orientation device for future lateral re-entry and workover operations.

Halliburton’s solution provided a cost-effective way to significantly increase reservoir contact, vary downhole flow rates and optimize production. By optimizing production rates, the well is expected to produce for a significantly longer time. The operator has implemented this solution in numerous other offshore wells and has been so successful that there are plans to continue the use of these technologies for future development of this and other fields.

MULTILATERAL SYSTEMS

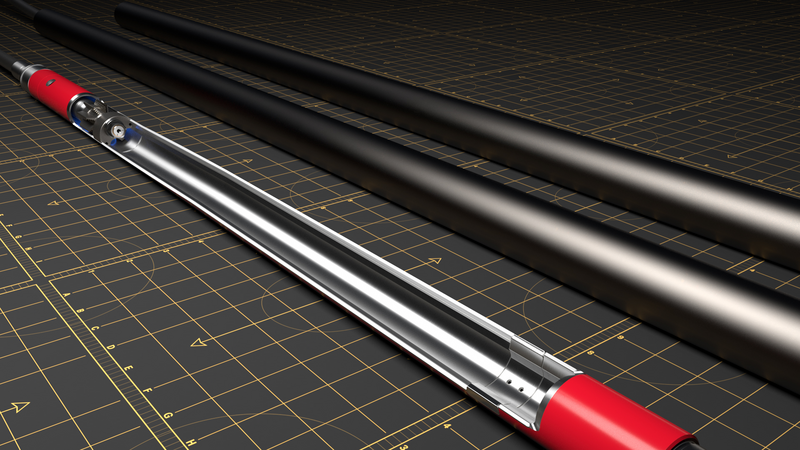

The MillRite® system is designed for use in new or existing wells that are to be developed as multilaterals for the exploitation of additional zones or reserves.

Download Data Sheet

The MillRite milled exit multilateral system provides consistent and geometrically controlled casing exit.

Collect, transmit, and analyze downhole data, and remotely control and monitor reservoir zones with Halliburton SmartWell® completion systems.

Greater profitability and a higher return on investment with innovative multilateral technology

Halliburton intelligent completions technology help accelerate production and improve decision-making to increase ultimate recovery and maximize asset value

Halliburton rotary steerable systems are engineered with advanced technologies to reduce well time and accurately place well in reservoir.