Search

Search

Search

Search

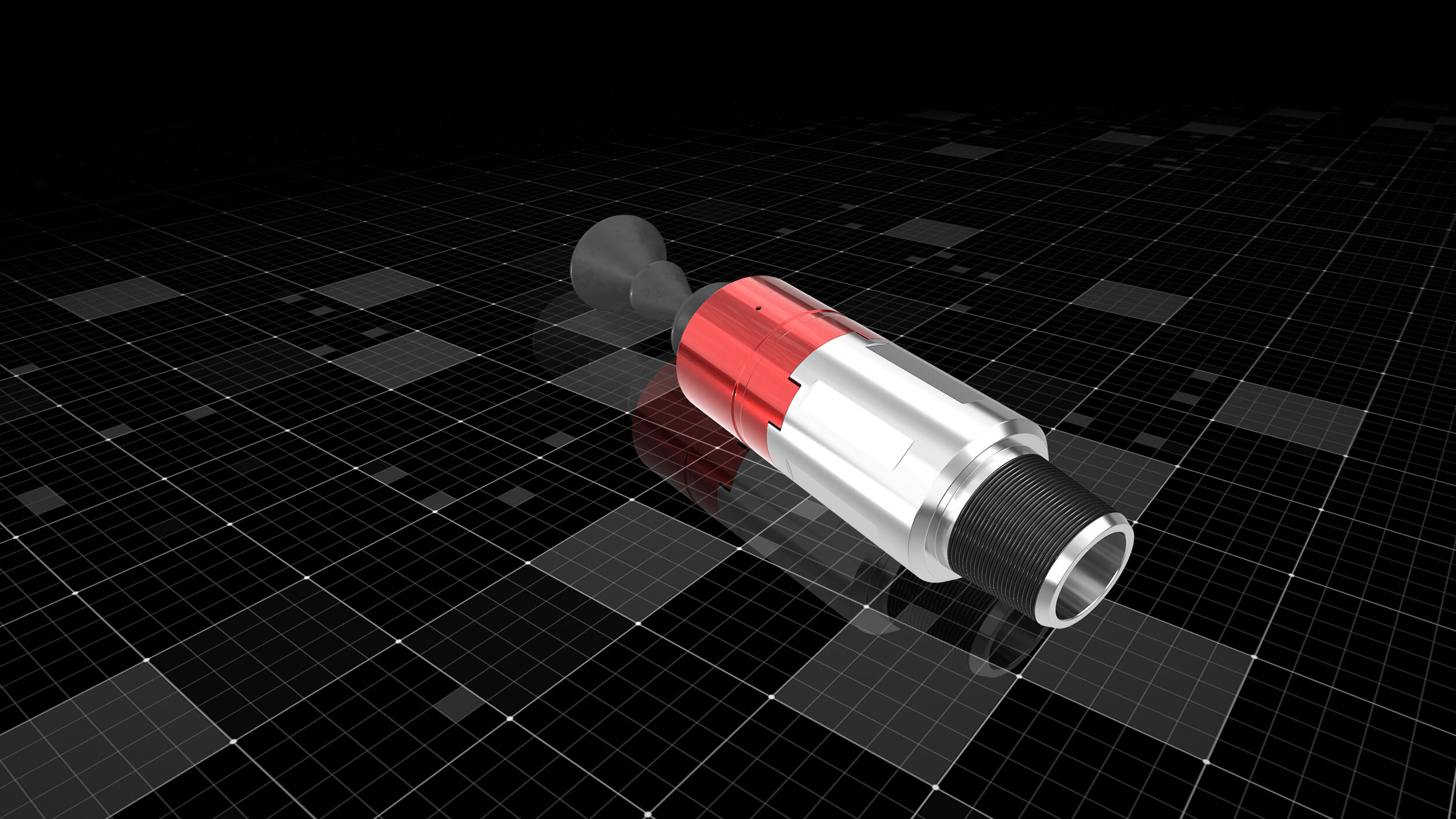

BHKA™ plug setting aid used to place cement plug during mature gas-well abandonment

Download PDFMature Fields

Isolate 1000+-m long well section as part of decommissioning plan

Australia

As part of a major operator’s decommissioning plan for more than 400 wells in Australia, reservoir and intermediate barriers are isolated by spotting cement plugs in separate stages. Deployment of an industry leading plug setting aid in one of these wells allowed Halliburton to successfully spot a 1239-m cement plug in a single run. This covered the required intervals with a single barrier and significantly reduced rig time and costs for the operator.

During a plug and abandonment campaign, an operator faced challenges isolating reservoir and intermediate barriers along a 1000+-m well section that deviated more than 50°. Previous cement solutions required more than seven days to achieve caprock isolation using a conventional balanced plug method to help reduce operational risks.

In this highly deviated well, pulling out of hole (POOH) after the cement plug is in place could increase the potential for fluid swabbing and contamination—both causes of cement plug failure. Because this well was critical to regulatory approval, it was necessary to engineer a solution for more efficient zonal isolation and lay the foundation for similar wellbore geometries while significantly reducing rig time.

Halliburton recommended the BHKA™ plug setting aid (disconnect tool) to isolate the interval through the placement of a single, undisturbed cement plug, which would maximize both operational efficiency and effectiveness.

The BHKA plug setting aid stands out as an industry-leading solution, widely adopted in both onshore and offshore wells. This innovative tool incorporates a displacement dart-driven disconnect mechanism, which selectively releases a section of the string. By doing so, it eliminates the need for stinging out, as the tailpipe remains securely within the balanced cement plug.

This design not only prevents fluid swabbing and contamination risks but also empowers operators to safely position longer cement plugs without the risk of work string entanglement. Furthermore, the flexibility extends to the cement slurry itself, allowing tailoring to specific design criteria—such as compressive strength and gel development—for the extended length of the plug, ultimately optimizing overall operations.

Reduction in rig time

Days rig time savings

USD saved

The work string was run to a measured depth of 2379 m and navigated through the highly deviated section without concerns for torque or tension stress. A 1239-m cement plug was successfully pumped and displaced with the BHKA plug setting aid solution. The immersed tailpipe was released at the designed pressure, which allowed for optimized and effective well abandonment.

The BHKA plug setting aid allowed the operator to reduce rig time by more than 50%, which saved more than USD 350,000. The success of this operation created an avenue for the operator to safely pump longer cement plugs in a single run across the entire plug and abandonment campaign to achieve the required zonal isolation.