Search

Search

Search

Search

Operator saves an estimated $200,000 in completion costs on plug-and-perf operation

Download PDFUnconventional

Eliminate cost and time associated with millout

North Dakota, Williston Basin

In a quest to minimize completion costs, the operator was looking to remove the typically required post-fracturing treatment cleanout from the plug-and-perforate process.

After the fracturing treatment had been completed, both wells exhibited positive performance during initial flowback operations.

An operator in the Williston Basin wanted to reduce or eliminate the cost and time associated with post-fracturing treatment millout operations. Two wells, similar in construction with a ~10,000-foot vertical section and a ~10,000-foot lateral, were completed using Halliburton fully dissolvable Illusion frac plugs.

n more than 49 stages, there were zero issues in running the plugs to depth, setting, and withstanding fracturing treating pressures. After the fracturing treatment was completed, the two wells were flowed back for three days. Both wells met operator expectations during initial flowback operations, allowing the operator to place both wells onto production without completing a coiled tubing millout.

n an ongoing effort to reduce the cost of completing a well using the plug-and-perforate method, an operator in the North Dakota Williston Basin was looking to reduce or completely remove the time and investment required to complete a post-fracturing treatment millout, an operation which has become standard practice with composite fracturing plugs.

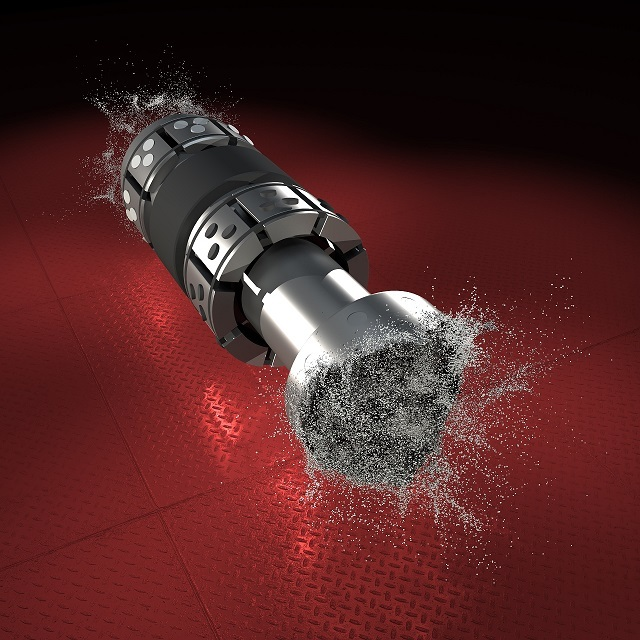

Despite dissolvable technology being relatively new, the Illusion frac plug has had over 1,000 successful installations in the Williston Basin alone. Halliburton knew that this fully dissolvable plug could reliably stand up to the challenges of this operation, while helping meet the operator’s goal of eliminating post-frac millout. This plug features a large inside diameter that allows for fluid to flow through the plug during flowback or production, and a fully dissolving rubber element and metallic body. It is run-in-hole just as a composite frac plug would be, making installation quick and easy.

Illusion plugs were pumped and set at desired depth

wells placed on production without millout

days of millout operations saved

estimated saved

A total of 49 Illusion frac plugs were pumped and set at the desired depths with an average line speed of 570 ft/min through the vertical section and 450 ft/min in the lateral section of the wellbore. The plugs required minimal fluid volumes to pump down, minimizing the risk of formation damage and reducing completion costs. All 49 plugs held up to fracturing treating pressures, even after hours of down time and wellbore fluid exposure.

Upon completion of the fracturing treatment, the wells flowed back successfully. The operator then rigged up the production equipment and allowed both wells to continue to produce. A post-fracturing treatment millout was never needed, saving the operator an estimated $200,000 in completion costs on these two wells. Eliminating the millout process wiped out operator concerns, giving them peace of mind as well as extra dollars back in their pocket.

Frac Plugs

The Illusion frac plug not only helps alleviate the cost and time of plug mill-out operations, but it also helps remove the risk associated with coiled tubing.

Download Data Sheet

This high-performance frac plug provides zonal isolation of the wellbore during stimulation treatment and customized dissolution times